Heating micro-evaporation mosquito killer

A mosquito killer and mosquito technology are applied in the field of mosquito killing and can solve problems such as poor mosquito killing effect of the mosquito killer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

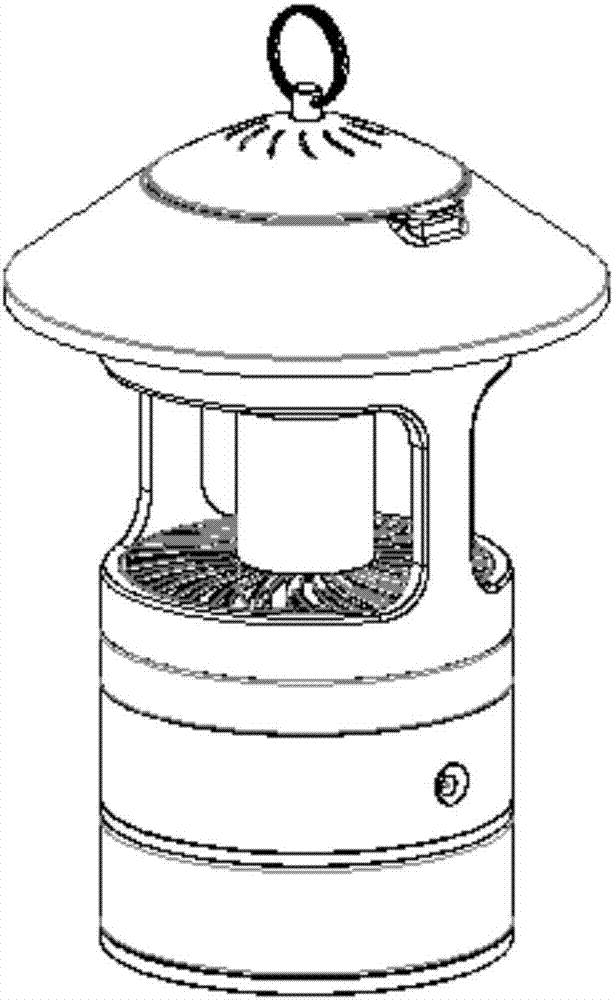

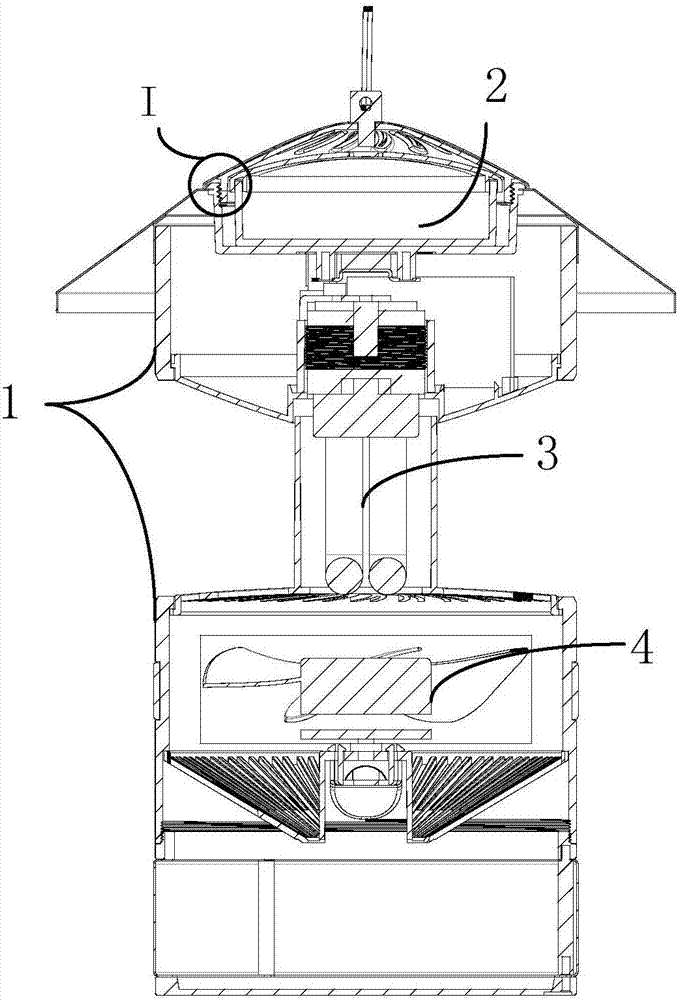

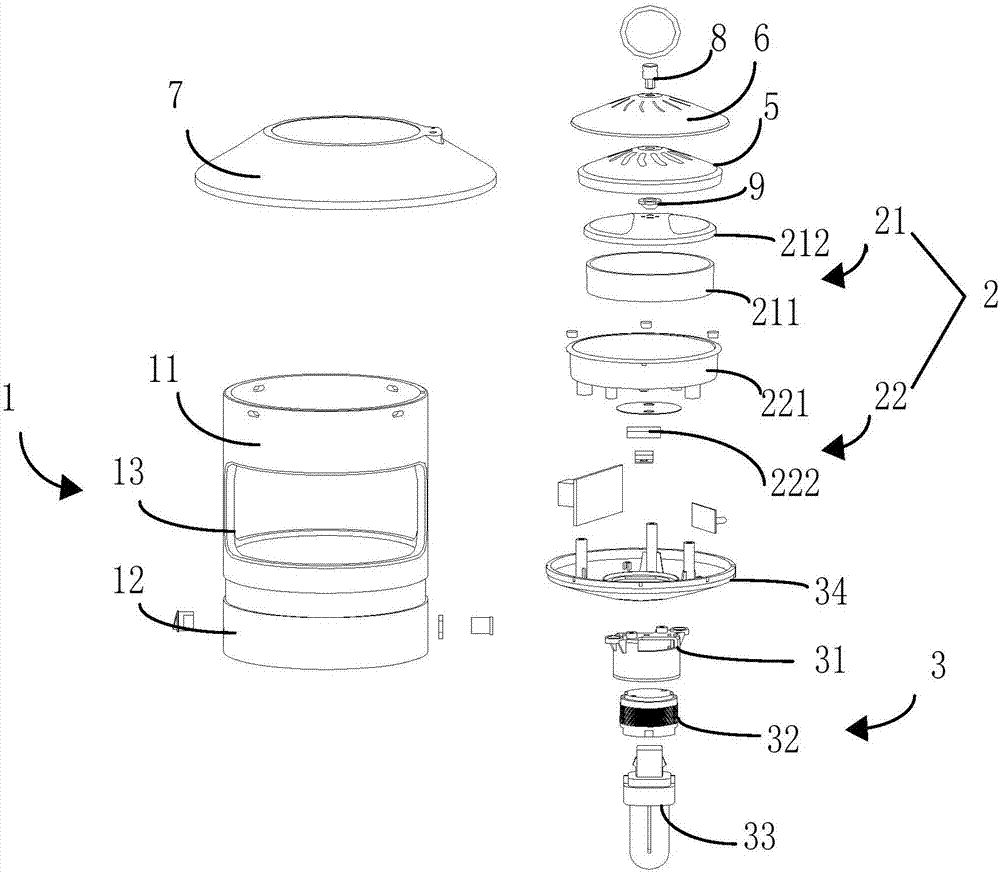

[0062] This embodiment provides a heating micro-evaporation mosquito killer, please refer to Figure 1 to Figure 5 ,include:

[0063] Housing 1, the housing 1 includes an upper cylinder 11, a lower cylinder 12, and a rib 13 arranged between the upper cylinder 11 and the lower cylinder 12; between the upper cylinder 11, the lower cylinder 12 and the rib 13 Form a trapping space;

[0064] The light lure mechanism 3 is installed in the housing 1 and emits a light source to the outside to attract mosquitoes to the trapping space;

[0065] The warm lure mechanism 2 is arranged on the upper part of the light lure mechanism 3, including a trapping device 21 for containing liquid bait and a heating device 22 located below the trapping device 21;

[0066] The collection mechanism 4 is arranged at the lower part of the light-induced mechanism 3, and is used to collect and kill mosquitoes attracted by the light-induced mechanism 3 and the temperature-induced mechanism 2.

[0067] Duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com