Joint traction type humanoid robot hand

A robotic hand and pull-type technology, applied in the field of bionic robots, can solve the problem that the structure cannot meet the requirements of continuous improvement of product performance, and achieve the effect of good bionic effect, light weight, and ingenious mechanism conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

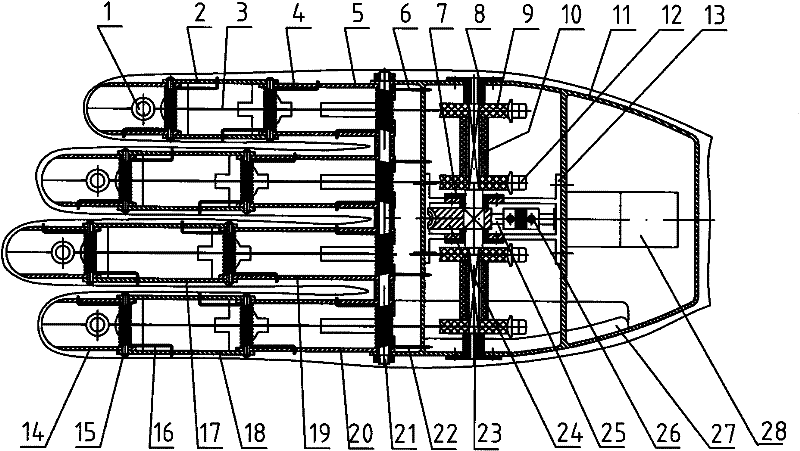

[0013] Attached below figure 1 to attach Figure 5 Embodiments of the present invention are further described.

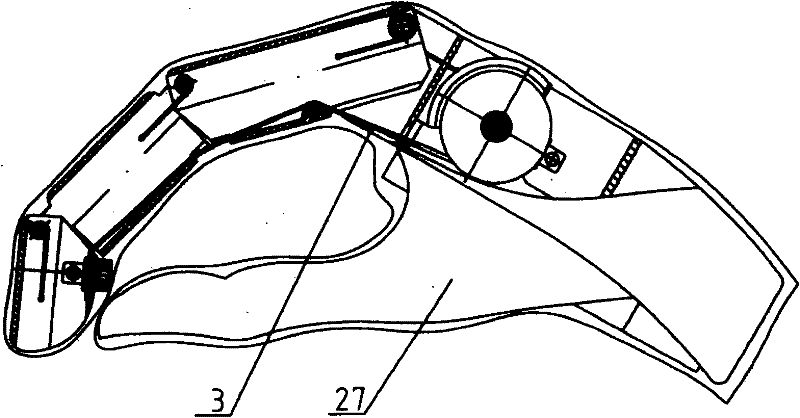

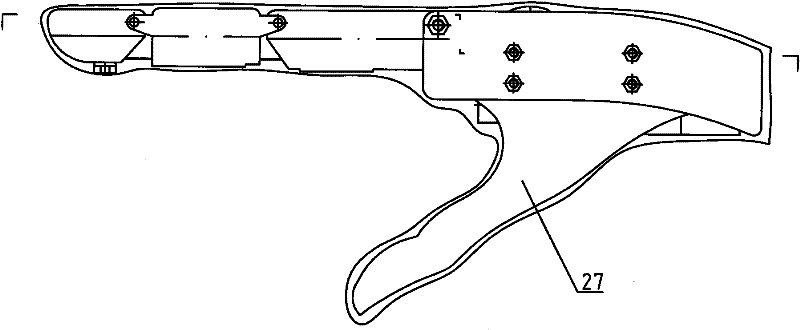

[0014] like figure 1 , figure 2 and image 3 As shown, the joint pulling type humanoid robot hand of the present invention comprises thumb 27, index finger, middle finger, ring finger and little finger as a whole, wherein:

[0015] Described thumb 27 is a curved overall thumb, fixed on the palm frame 3 (see figure 1 ).

[0016] The structures of the index finger, middle finger, ring finger and little finger are as follows: figure 2 and image 3 Shown, as can be seen from the figure, the index finger and the ring finger are all connected as one by the front phalanx 14, the middle phalanx 18 and the back phalanx 20 through the phalanx 15; Section 17 and middle finger rear phalanx 19 are connected as a whole by knuckle shaft 15; described little finger is connected as a whole by front knuckle 14, little finger middle knuckle 2 and little finger rear knuckle 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com