Integrated pneumatic variable-stiffness mirror milling flexible supporting device with real-time thickness measuring function

A flexible support and integrated technology, applied in the direction of positioning device, support, measuring/indicating equipment, etc., can solve the problem of not considering the position adjustment of the ultrasonic thickness measuring probe, not considering the center position support, etc., to suppress vibration and increase the effective area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

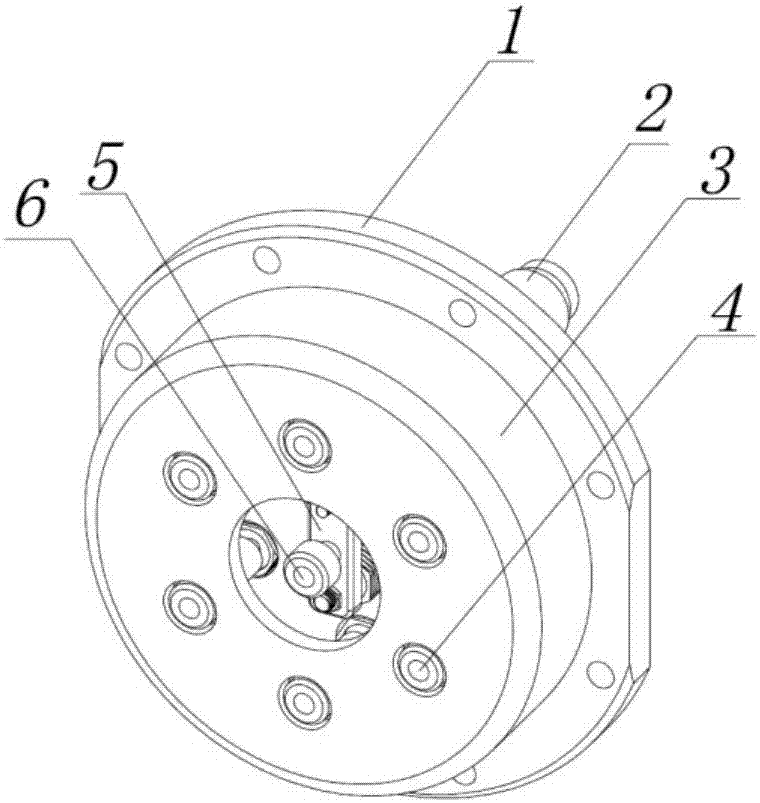

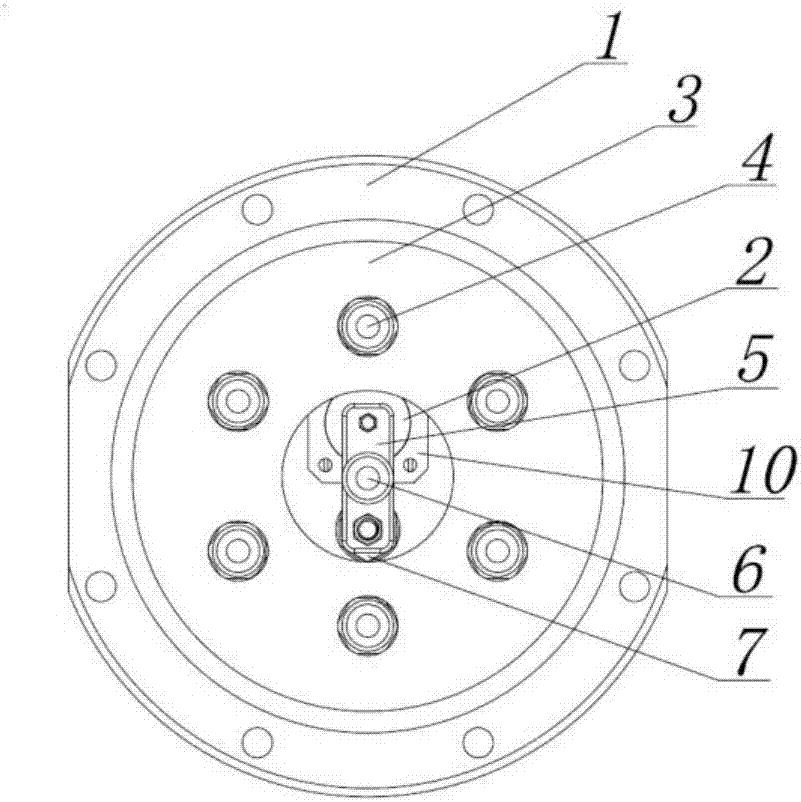

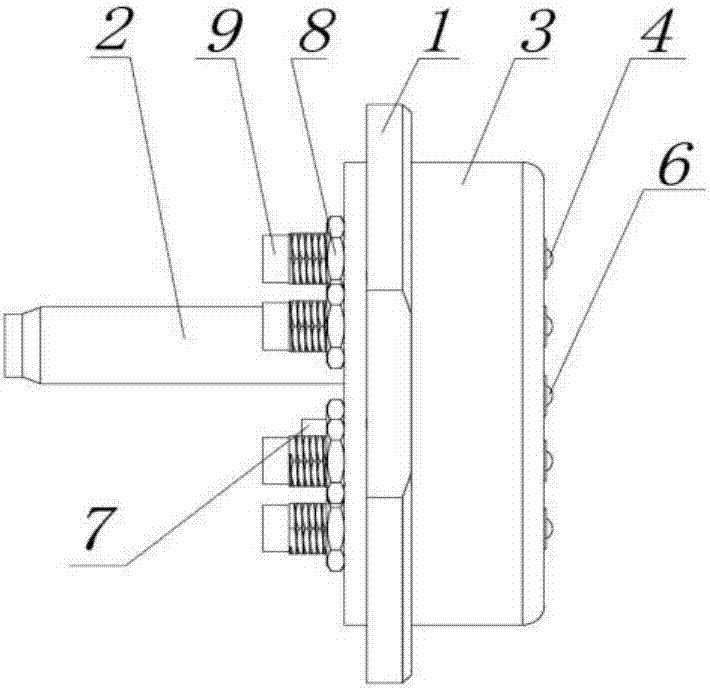

[0020] As shown in the accompanying drawings, the integrated real-time thickness measuring pneumatic variable rigidity mirror milling flexible support device 15 of the present invention includes a base 1, and an end cover 3 is fixed on the right side of the base 1, and the end cover 3 can be fixedly connected with the base 1 by bolts, and a through hole for connecting with the processing robot is opened in the outermost circumferential direction of the base 1 .

[0021] The base 1 is respectively provided with a sensor fixing stepped hole and a main thread through hole, and the central axis of the sensor fixing stepped hole and the central axis of the main thread through hole are parallel to the central axis of the base 1 And they are arranged symmetrically on both sides of the central axis of the base 1 respectively, and the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com