Waste compression device in circuit substrate packaging process

A technology for circuit substrates and compression devices, applied in the field of compression devices, can solve the problems of increased labor force, increased waste, multilateral scraps, etc., and achieves the effects of increasing the utilization rate of effective space, facilitating handling and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical scheme of the present invention will be further described below in conjunction with the drawings.

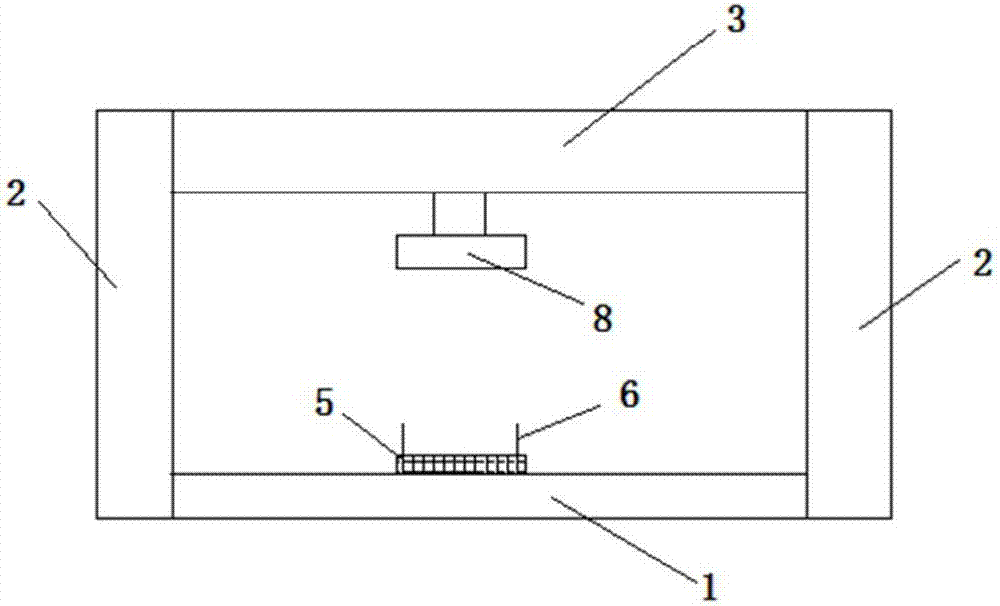

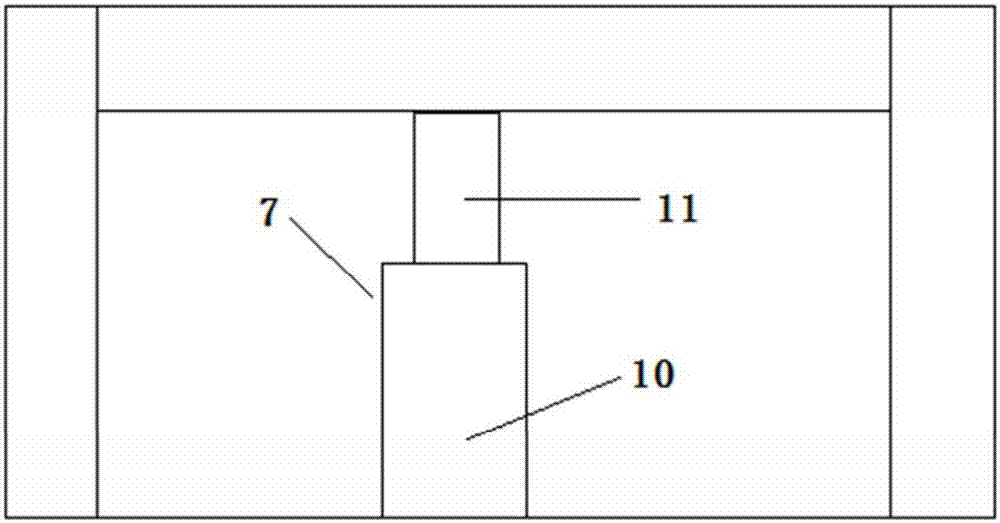

[0013] Such as Figure 1-3 As shown, the waste compression device in the circuit board packaging process of the present invention includes a square base 1, guide support columns 2 respectively provided on the four corners of the base 1, and a square top plate 3. The four corners of the top plate 3 are provided with sliding plates. The block is connected to the guide support column 2 and can slide up and down. The square top plate 3 is also provided with a groove 4 to prevent foot sliding; the device also includes a nitrogen cylinder 7 arranged symmetrically between the guide support columns 2 on both sides. The nitrogen cylinder 7 includes a cylinder block 10 and a cylinder rod 11. The base 1 is provided with a carrier 5 and a box body 6 for storing waste materials. The upper surface of the carrier 5 is provided with a groove for engaging the box body 6 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com