Preparation method of dibutyltin oxide and its application in the synthesis of sucralose

A technology of dibutyltin oxide and dibutyltin dichloride, which is applied in the field of preparation of organic tin substances, can solve the problems of serious adsorption, side reactions, poor temperature and salt resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

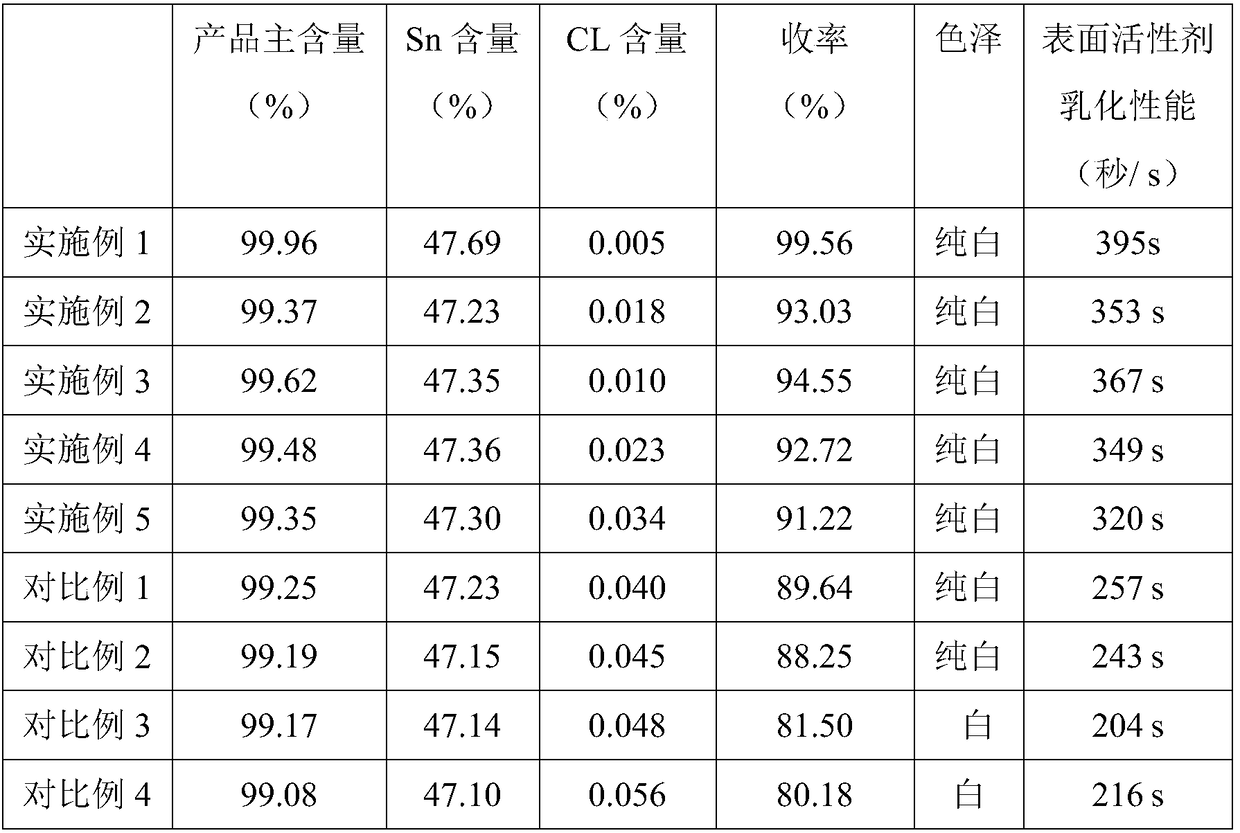

Examples

preparation example Construction

[0036] The invention provides the preparation method of dibutyltin oxide, at least comprises the following steps:

[0037] (1) Synthesis of tetrabutyltin: add magnesium powder, composite solvent and n-butyl chloride to the reactor, heat up to reflux reaction for 0.5h, slowly add dropwise the mixed solution of n-butyl chloride and tin tetrachloride, reflux reaction for 3h, Cool to room temperature, add 10% hydrochloric acid aqueous solution, stir evenly, separate the organic layer, and concentrate the organic layer under reduced pressure to obtain a colorless liquid tetrabutyltin;

[0038] (2) Synthesis of dibutyltin dichloride: add tetrabutyltin and catalyst in the reactor in step (1), replace with nitrogen 3 times, slowly add tin tetrachloride dropwise, control the temperature in the reaction system to be less than 80°C, After the dropwise addition, keep warm at 65°C for 1h, raise the temperature to 136°C, keep warm for 3h, cool to room temperature, add 10% hydrochloric acid ...

Embodiment approach

[0055] In one embodiment, the Gemini cationic surfactant is prepared by reacting tertiary amines, concentrated hydrochloric acid and epichlorohydrin; the tertiary amines include dodecyldimethyl tertiary amine, dodecylphenylbutyl One or more of tertiary amines.

[0056] In one embodiment, the preparation method of described Gemini cationic surfactant comprises the following steps:

[0057] (1) Add tertiary amine and concentrated hydrochloric acid into the reactor in a molar ratio and slowly heat up to 60°C, keep the temperature for 5 hours, and cool to obtain tertiary amine hydrochloride;

[0058] (2) Add tertiary amine hydrochloride, tertiary amine, epichlorohydrin and n-propanol into the reactor, heat up to 65° C., keep the reaction for 8 hours, and concentrate under reduced pressure to obtain Gemini cationic surfactant.

[0059] In one embodiment, the molar ratio of the tertiary amine to the epichlorohydrin in the Gemini cationic surfactant is (1-1.3):1.

[0060] In one em...

Embodiment 1

[0079] The preparation method of dibutyl tin oxide at least comprises the following steps:

[0080] (1) Synthesis of tetrabutyltin: add magnesium powder, composite solvent and n-butyl chloride to the reactor, heat up to reflux reaction for 0.5h, slowly add dropwise the mixed solution of n-butyl chloride and tin tetrachloride, reflux reaction for 3h, Cool to room temperature, add 10% hydrochloric acid aqueous solution, stir evenly, separate the organic layer, and concentrate the organic layer under reduced pressure to obtain a colorless liquid tetrabutyltin;

[0081] (2) Synthesis of dibutyltin dichloride: add tetrabutyltin and catalyst in the reactor in step (1), replace with nitrogen 3 times, slowly add tin tetrachloride dropwise, control the temperature in the reaction system to be less than 80°C, After the dropwise addition, keep warm at 65°C for 1h, raise the temperature to 136°C, keep warm for 3h, cool to room temperature, add 10% hydrochloric acid aqueous solution, filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com