Pulling and pressing combined bearing manner large-tonnage anchor cable and manufacturing and installing method

A load-bearing mode and large-tonnage technology, applied in excavation, sheet pile walls, construction, etc., can solve problems such as damage and large stress concentration, and achieve the effects of simple equipment, increased shear force, and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A large-tonnage anchor cable in a combination of tension and compression load-bearing mode and a method for making and installing it. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

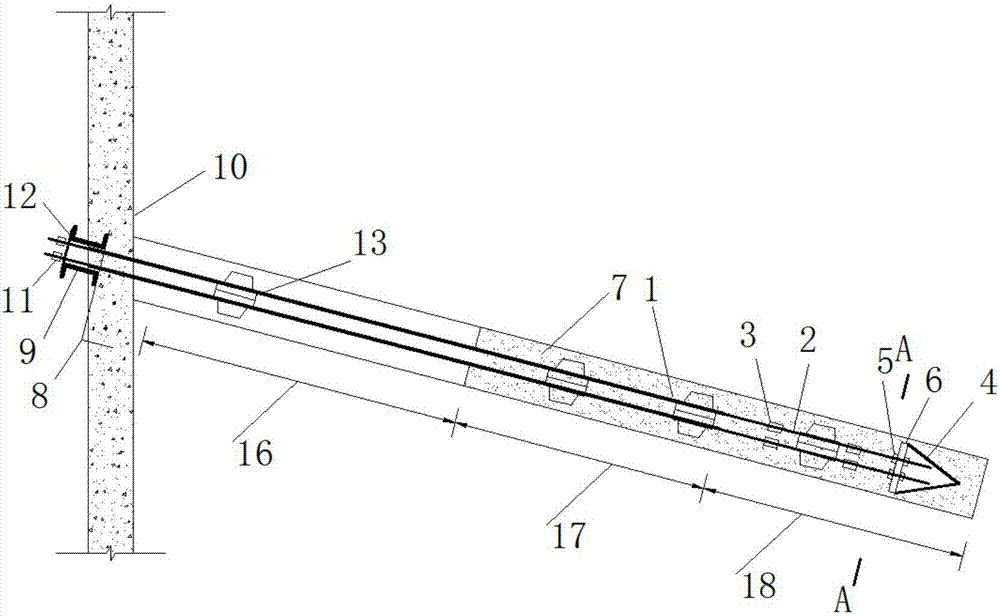

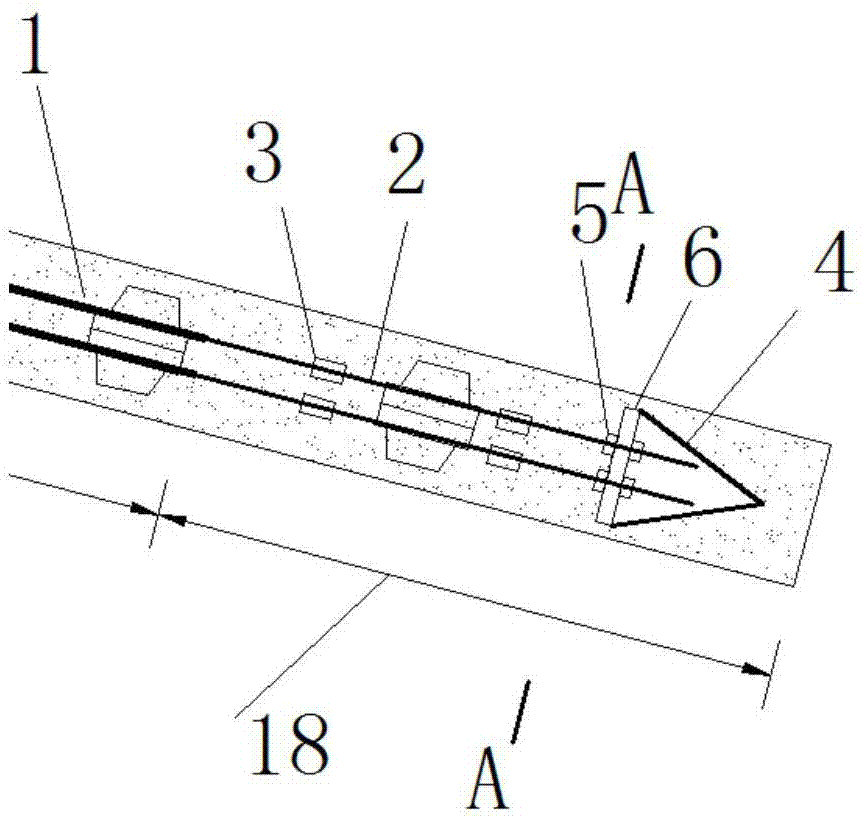

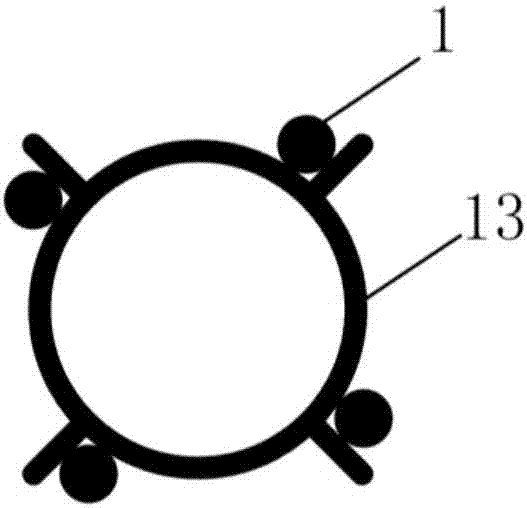

[0038] Such as figure 1 and figure 2 As shown, a large-tonnage anchor cable in a combined tension-compression bearing mode includes a tension anchor section 18, a pressure anchor section 17 and a free section 16 from bottom to top, and the tension anchor section 18 is used as a pressure bearing body for the pressure anchor section 17. , the steel strands of the tension anchoring section 18 are stripped of plastic outsourcing and grease, and the tension anchoring section 18 includes a shear pin 3, a pressure bearing plate 6 and a cone-shaped guide head 4 from top to bottom, and the shear pin 3 is set On each bundle of steel strands, the shear pins 3 are hollow cylindrical, and the steel strands pass t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap