Stand column aluminum product and wall leaning aluminum product connection structure

A technology for connecting structures and aluminum materials, applied in the direction of walls, building components, building structures, etc., can solve the problems of easy to hide dirt and dirt, exposed to the outside of the column aluminum material, cumbersome installation, etc. Beautiful appearance and easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

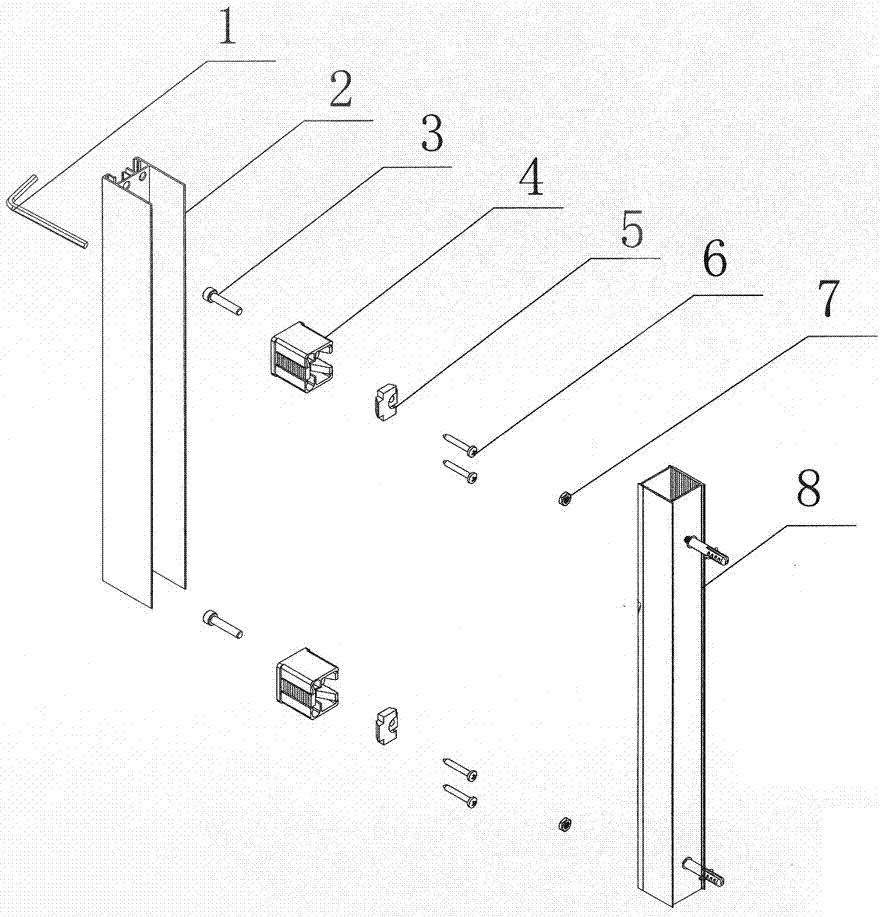

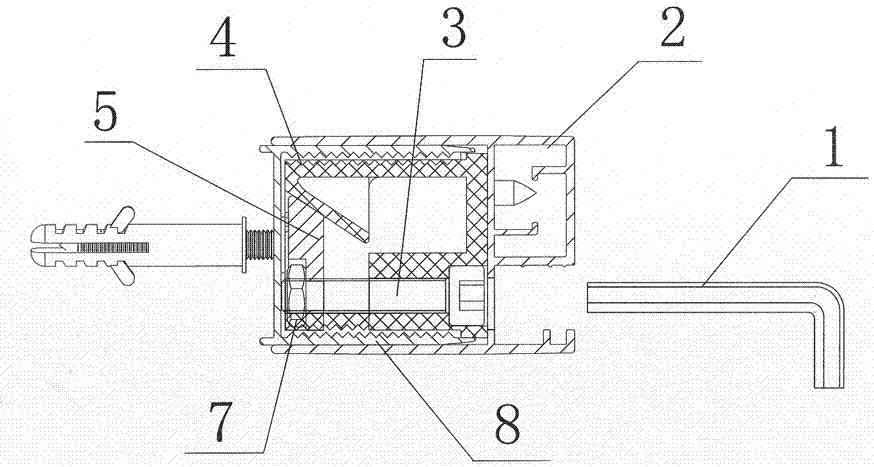

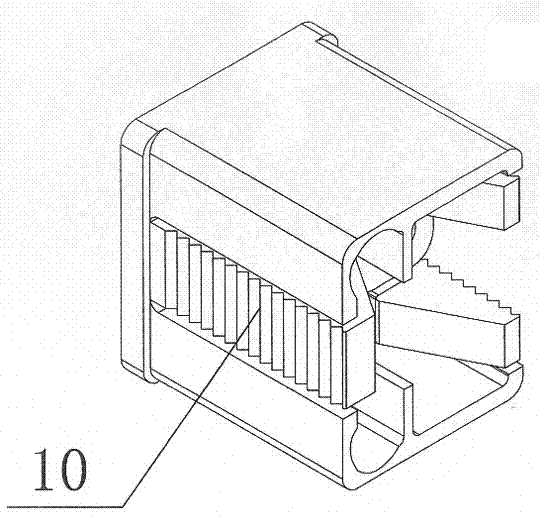

[0016] As shown in the accompanying drawings, a connection structure between a column aluminum material and a wall aluminum material includes a column aluminum material 2 and a wall aluminum material 8, and a pre-connection module is provided inside the column aluminum material 2, and the pre-connection module It is composed of screws 3, locking plastic parts 4, sliders 5 and locknuts 7 connected in sequence, and the pre-connection module is fixedly connected to the column aluminum material 2 through cross-recessed pan head screws 6. Both sides of the locking member are respectively provided with serrations I10, wherein the serrations on one side are arranged in the middle position, and the serrations on the other side are arranged in the upper and lower positions. The aluminum wall 8 is provided with a notch 9 matching the pre-connection module, and the two sides of the aluminum wall 8 are provided with serrations II11 matching the serrations I10 on both sides of the locking m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com