Washing machine

A washing machine and washing tub technology, applied in the field of washing machines, can solve the problems of dirt storage, bacteria breeding, and the inability to disassemble and clean the inner and outer tubs, so as to achieve the effects of saving materials, saving water, and avoiding the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

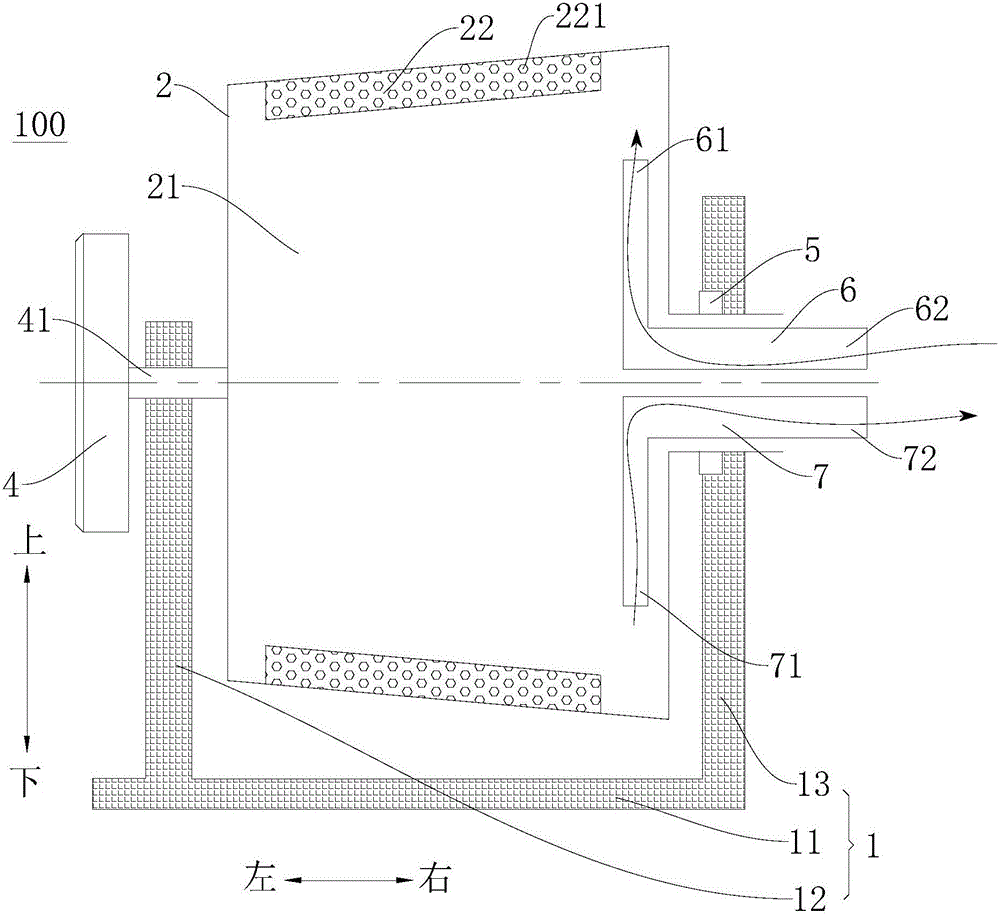

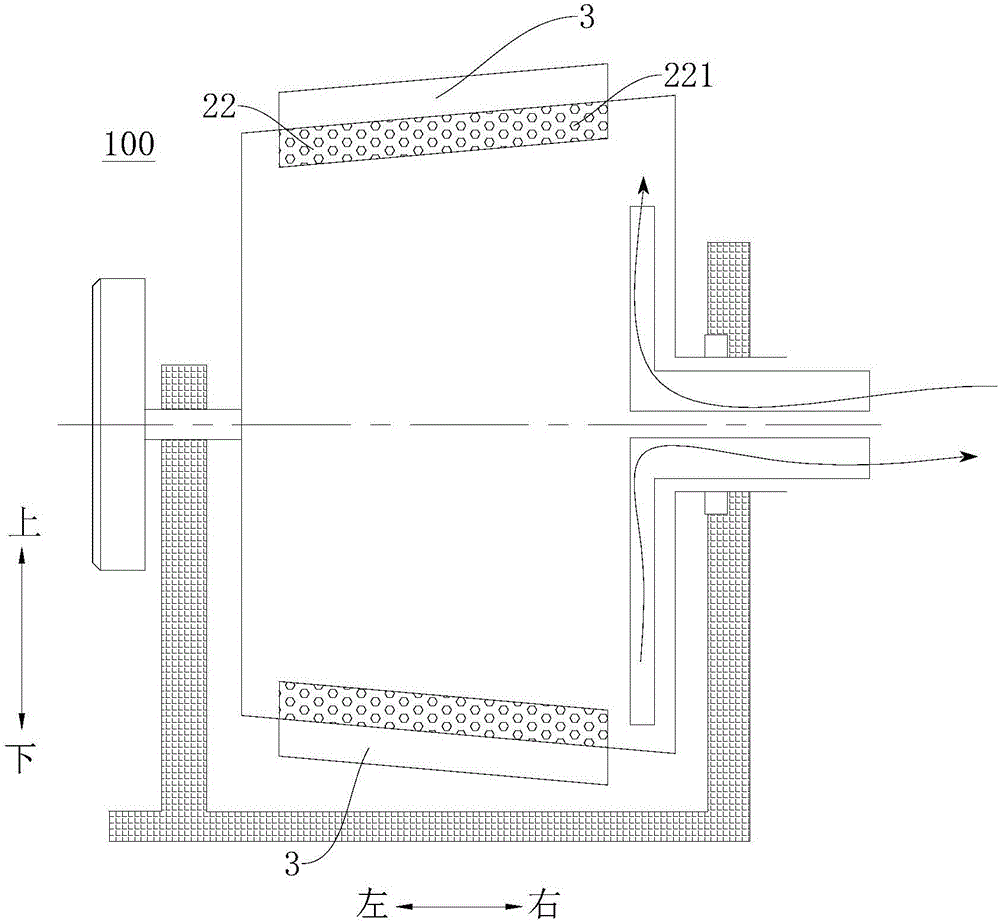

[0072] refer to Figure 1 to Figure 4 , according to the embodiment of the present invention, the washing machine 100 includes: a base 1 , a washing tub 2 , a sump 3 , a driving member 4 , a support assembly 5 , a water inlet pipe 6 and a drain pipe 7 .

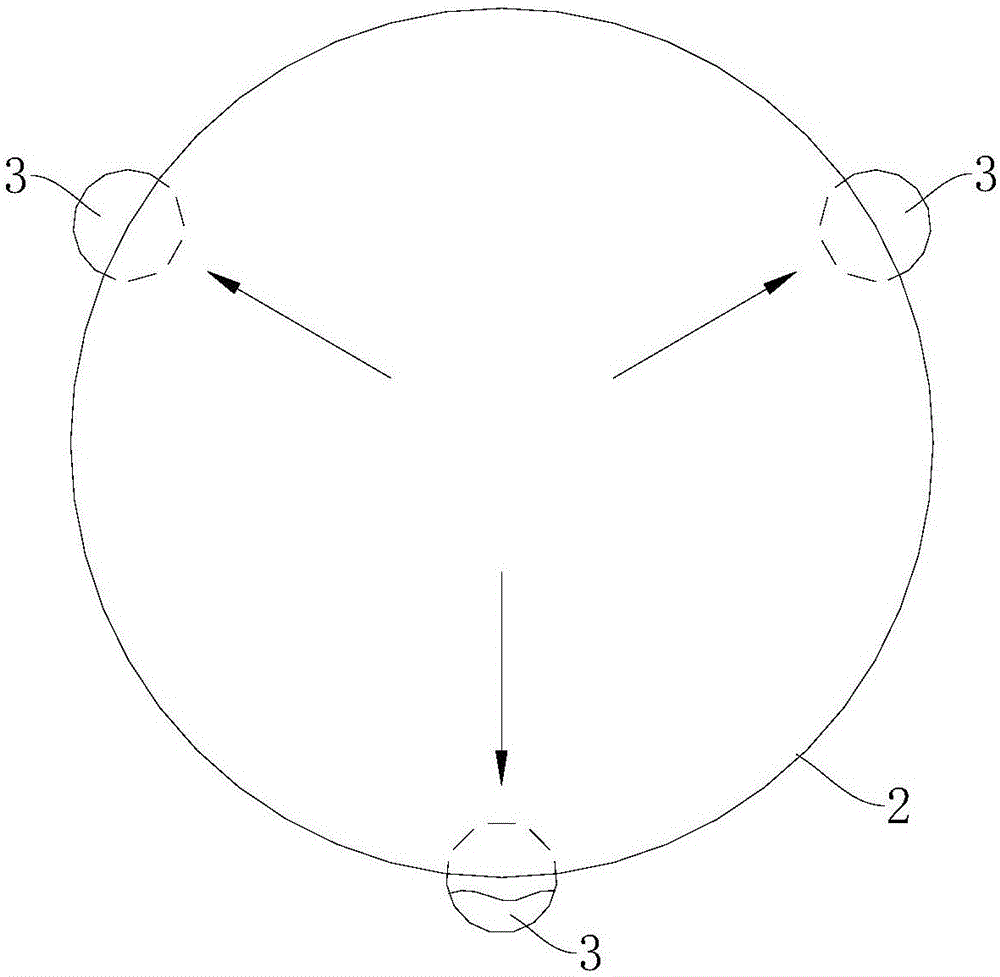

[0073] Specifically, the washing bucket 2 is rotatably arranged on the base 1 around a horizontal rotation axis, and the washing bucket 2 defines a washing chamber 21, and clothes can be put into the washing chamber 21 to be washed. refer to Figure 2 to Figure 4 Lifting ribs 22 can be formed on the inner peripheral wall of the washing tub 2, and the lifting ribs 22 can help to lift the clothes, thereby contributing to the full washing of the clothes. The lifting ribs 22 can be provided with a plurality of water-permeable holes 221. The water in the washing chamber 21 can further flow out through a plurality of water permeable holes 221 .

[0074] The sump 3 can be arranged on the washing bucket 2, and the sump 3 is opposit...

Embodiment 2

[0088] refer to Figure 5 and combine figure 1 and figure 2 , The structure of the second embodiment is basically the same as that of the first embodiment, the difference is that the sump 3 is not provided in the second embodiment, and in addition, the pump in the first embodiment is replaced by a blower 8 in the second embodiment.

[0089] Specifically, refer to Figure 5 , according to some specific embodiments of the present invention, the washing machine 100 further includes: a blower 8 , the blower 8 communicates with the washing chamber 21 , and the blower 8 is used for introducing air into the washing chamber 21 . For example, a ventilation hole is formed on the support assembly 5, one end of the ventilation hole is connected to the blower 8 and the other end is communicated with the washing chamber 21, or the suction pipe of the blower 8 directly extends into the washing chamber 21, so that the blower 8 can blow the outside The compressed air in the washing chamber...

Embodiment 3

[0092] refer to Figure 6 and combine figure 1 and figure 2 The structure of the third embodiment is basically the same as that of the first embodiment, the difference is that the sump 3 is not provided in the third embodiment, and in addition, a partition 9 (such as a clothing baffle) is set inside the washing tub 2 in the third embodiment.

[0093] Specifically, refer to Figure 6 and combine figure 1 , according to some specific embodiments of the present invention, the washing machine 100 may also include: a partition 9, the partition 9 may be arranged between the lifting rib 22 and the water inlet pipe 6 and / or the drain pipe 7, that is to say the partition 9 may be opposite It is fixed inside the washing tub 2, thus, the partition 9 is installed in the washing tub 2, and when the washing tub 2 rotates, the partition 9 will rotate together with the washing tub 2. In the state where the water inlet pipe 6 and the drain pipe 7 are fixed, the clothes partition 9 can pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com