Robot shooting device

A launcher and robot technology, applied in the field of robots, can solve the problems of poor manufacturing process, high risk factor, unsuitable for civilian use, etc., and achieve the effect of high accuracy, good adaptability, and not easy to shoot by mistake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

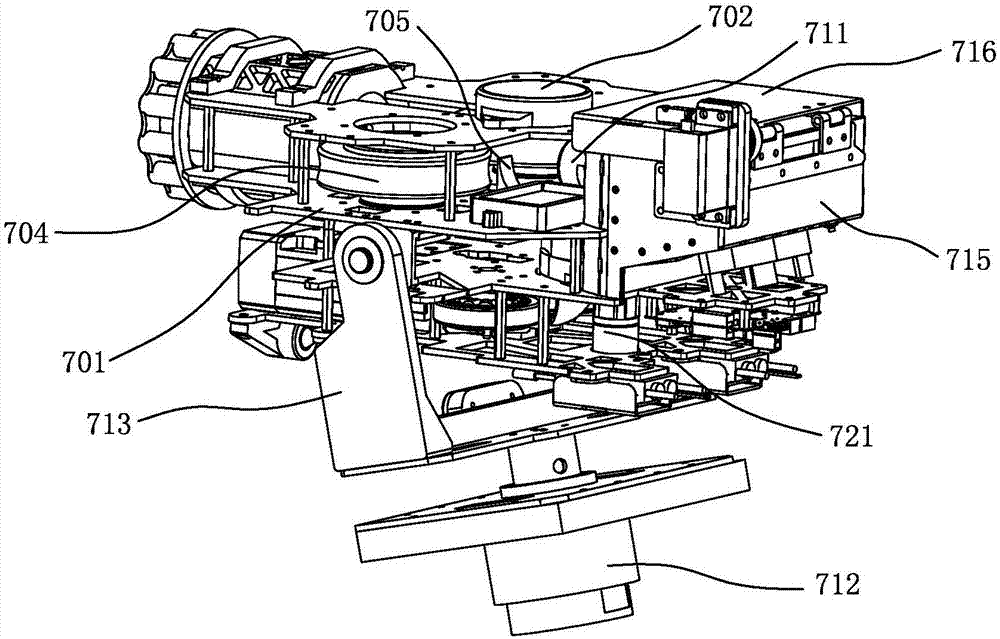

[0026] Such as Figure 1 to Figure 6 As shown, a robot launching device provided in this embodiment can launch two types of spherical materials with different sizes and materials at the same time. In this embodiment, projectiles of two sizes are used as examples for illustration.

[0027] Such as Figure 4 As shown, the robot launching device includes a base plate 701 and a feeding tube 702 arranged above the base plate 701. The large projectile 723 falls into the base plate 701 through the feeding tube 702 and enters the station to be fired. A firing cylinder is provided on one side of the station to be fired. 703, the telescopic end of the percussion cylinder 703 is provided with a percussion cover 711, and the percussion cover 711 is opposite to the large projectile 723.

[0028] The other side of the big projectile 723 is provided with a pair of rotatable friction launching wheels 704. The friction launching wheels comprise a rotor motor, the rotating shaft of the rotor m...

Embodiment 2

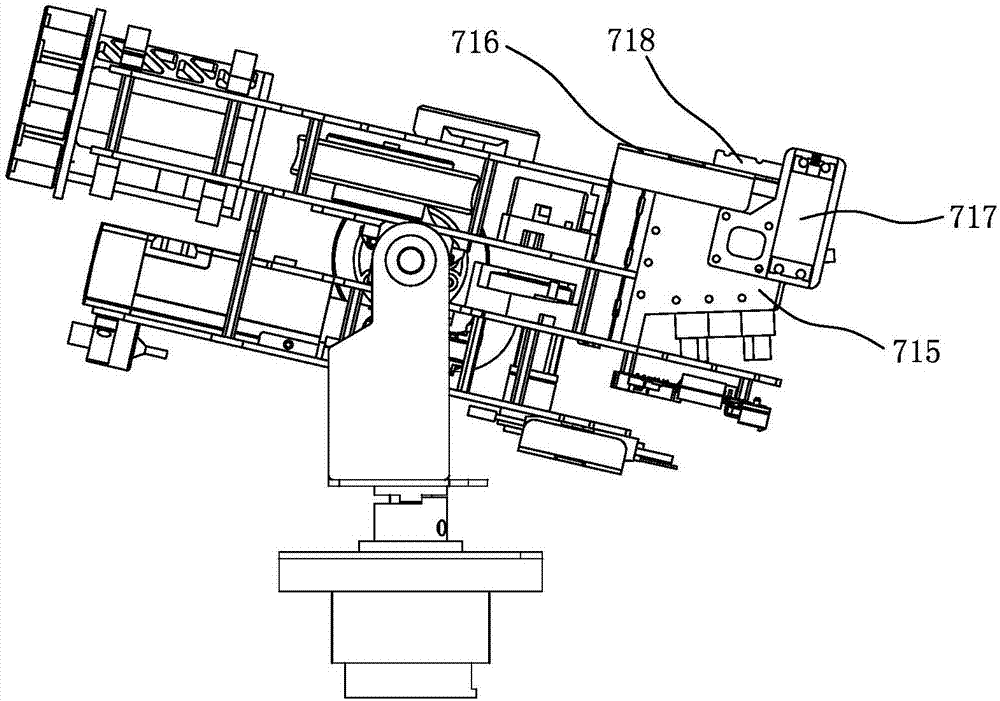

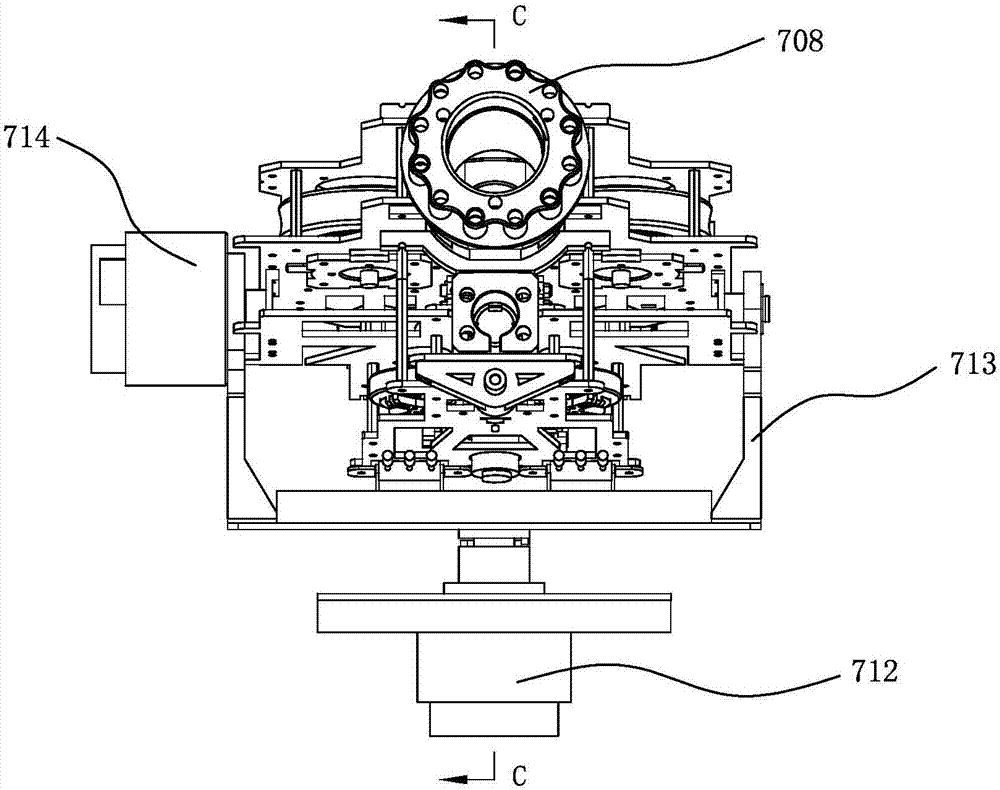

[0037] Such as Figure 7 As shown, the robot launching device in this embodiment is installed on a two-axis pan / tilt. In order to maintain the stability of the launching device, it is designed to only launch one kind of projectile. Therefore, the robot launching device in this embodiment is the same as that in Embodiment 1. The difference of the launching device of the present invention only lies in that each part relevant with launching small projectile is omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com