Multichannel ultrasonic flaw detection device and method

An ultrasonic flaw detection, multi-channel technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves for material analysis, cooling/ventilation/heating transformation, etc., can solve problems such as poor cooling effect, and achieve safe working performance. Effect of reducing temperature and preventing uncertain influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

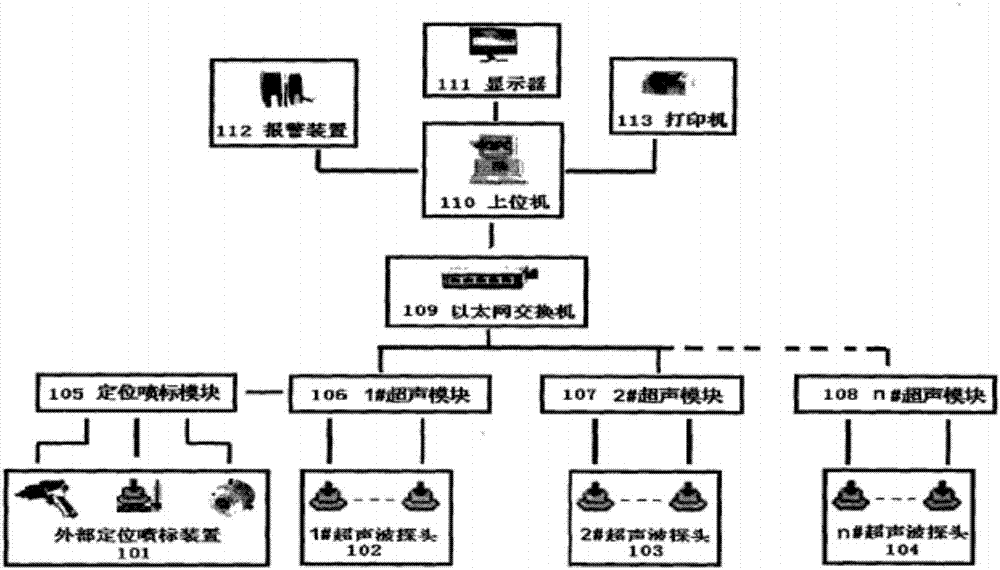

[0033] like Figure 1-Figure 4 As shown, it includes a display 111, a host computer 110, an alarm device 112, a printer 113, an Ethernet switch 109, an ultrasonic module 106, an ultrasonic module 107, an ultrasonic module 108, an ultrasonic probe 102, an ultrasonic probe 103, an ultrasonic probe 104, and a positioning spray label Module 105, external positioning label spraying device 101, the system is composed of multiple ultrasonic modules, each ultrasonic module is connected to 2-64 ultrasonic probes, each ultrasonic module is connected to the host computer through an Ethernet switch, and the host computer is connected to the host computer respectively The display, the printer, and the alarm device are connected; the positioning marking spraying module is connected to one of the ultrasonic probes, and the positioning marking spraying module is connected to an external positioning marking spraying device;

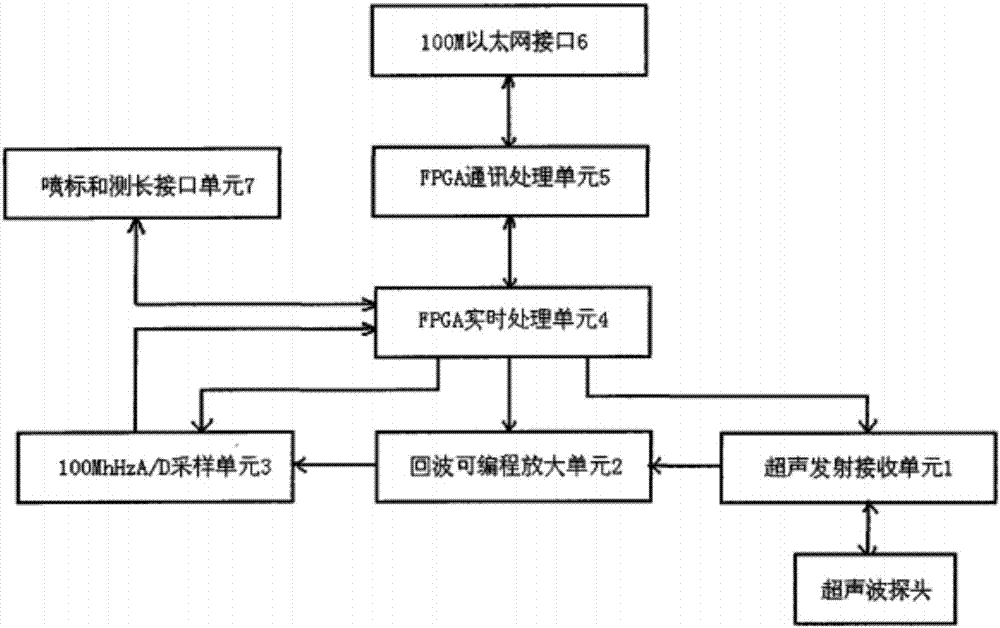

[0034] The ultrasonic module consists of an ultrasonic transmitting ...

Embodiment 2

[0051] A multi-channel ultrasonic flaw detection device, including a display 111, a host computer 110, an alarm device 112, a printer 113, an Ethernet switch 109, an ultrasonic module 106, an ultrasonic module 107, an ultrasonic module 108, an ultrasonic probe 102, an ultrasonic probe 103, an ultrasonic probe 104, Positioning and marking module 105, external positioning and marking device 101, the system is composed of multiple ultrasonic modules, each ultrasonic module is connected to 2-64 ultrasonic probes, each ultrasonic module is connected to the host computer through an Ethernet switch, and the host computer Then connect with the display, printer, and alarm device respectively; the positioning marking spraying module is connected with one of the ultrasonic probes, and the positioning marking spraying module is connected with an external positioning marking spraying device;

[0052] The ultrasonic module consists of an ultrasonic transmitting and receiving unit 1, an echo ...

Embodiment 3

[0075] Multi-channel ultrasonic flaw detection device, multi-channel ultrasonic flaw detection device, including display 111, host computer 110, alarm device 112, printer 113, Ethernet switch 109, ultrasonic module 106, ultrasonic module 107, ultrasonic module 108, ultrasonic probe 102, ultrasonic probe 103, ultrasonic probe 104, positioning marking module 105, external positioning marking device 101, the system is composed of multiple ultrasonic modules, each ultrasonic module is connected to 2-64 ultrasonic probes, and each ultrasonic module communicates with the The upper computer is connected, and the upper computer is connected with the display, the printer, and the alarm device respectively; the positioning and marking module is connected with one of the ultrasonic probes, and the positioning and marking module is connected with the external positioning and marking device;

[0076] The ultrasonic module consists of an ultrasonic transmitting and receiving unit 1, an echo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com