Automatic open-circuit method for supernormal heat generation of connector

A technology of connectors and self-disconnection, which is applied to the components, circuits, and connections of connecting devices, and can solve the problems of high cost, unreliability, and loss of elasticity of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

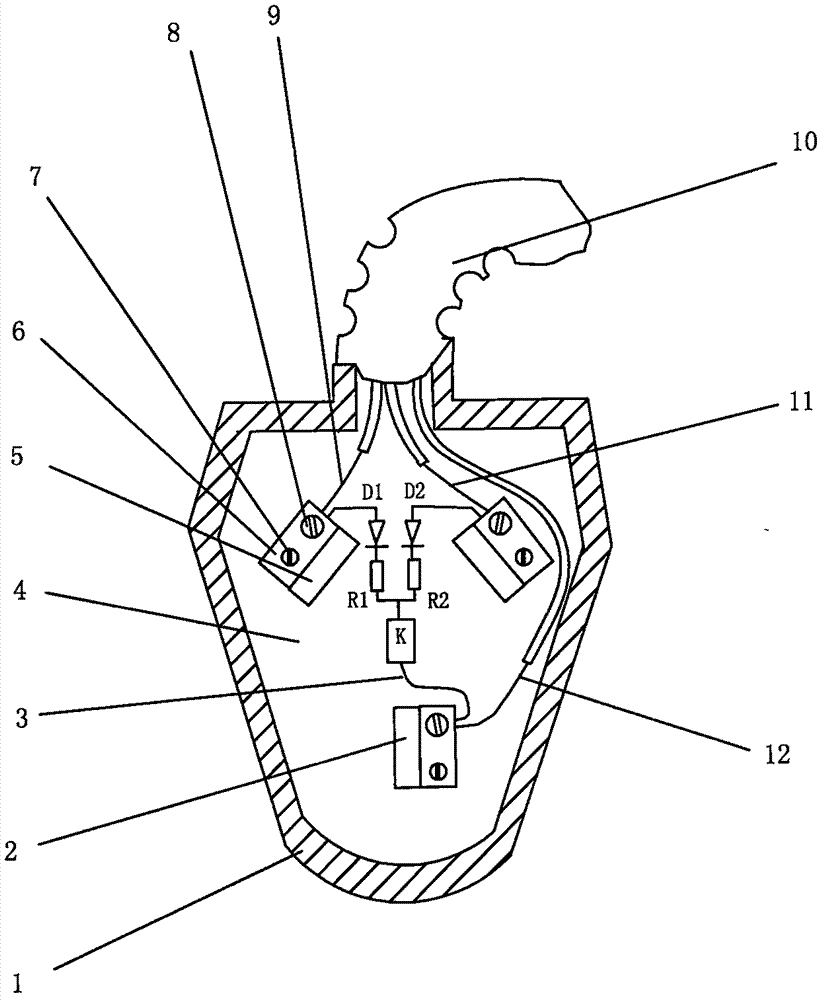

[0008] figure 1 It is a schematic diagram of the self-breaking circuit structure of the electric plug with abnormal heating. In the figure, 1 is the wall of the plug shell as an insulating member, 2 is the ground wire insert (that is, the ground wire metal insert), 3 is the wiring of the thermal switch circuit, 4 is the plug base plate as the insulating member, and 5 is the power supply insert (That is, the two power supply metal inserts correspondingly distributed on the left and right, such as single-phase plugs, one is live wire and the other is neutral wire), 6 is the insert seat, 7 is the fixing screw of the insert seat, 8 is the power connection screw, 9 is a power cord, 10 is an outer soft wire of a plug, 11 is another power cord, 12 is a ground wire, D1 and D2 are diodes, R1 and R2 are current-limiting resistors, and K is a thermal switch. The power supply plug 5 and the ground wire plug 2 are integrated with the plug seats on their respective sides, the plug seats ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com