Cable installing robot

A cable installation and robot technology, applied in cable installation, cable installation devices, manipulators, etc., can solve the problems of increasing unnecessary losses in construction, signal attenuation, etc., and achieve the effect of simple and efficient work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

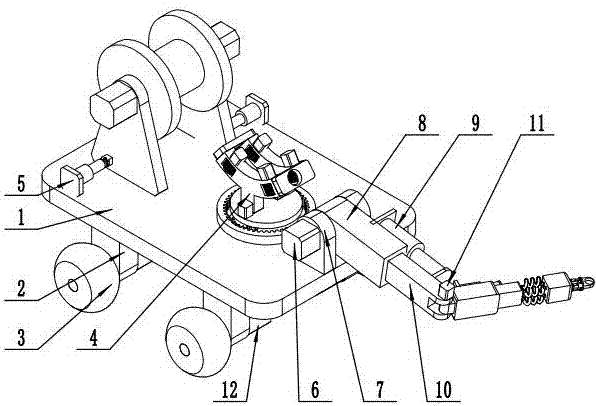

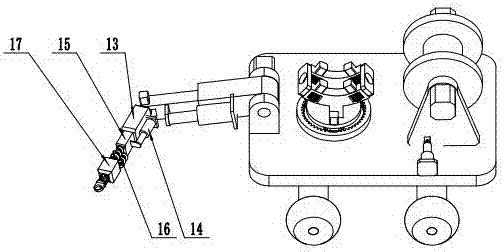

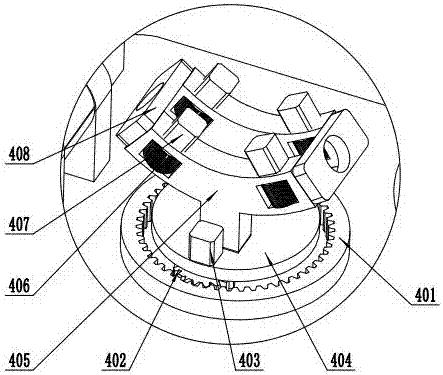

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a cable installation robot includes a platform 1, four wheel frames 2, four wheels 3, a lead device 4, two first electric cylinders 5, a first servo motor 6, a first motor base 7, a first telescopic Cover 8, second electric cylinder 9, first telescopic rod 10, second servo motor 11, four sixth servo motors 12, second telescopic sleeve 13, third electric cylinder 14, second telescopic rod 15, spring 16, Forearm 17, rear end plate 18, fourth electric cylinder 19, front end plate 20, splint 21, third servo motor 22, two supports 23, cable turntable 24, two bearings 25, is characterized in that: described platform 1 The rear portion is provided with a chute; the upper ends of the four wheel frames 2 are installed on the four corners of the platform 1 respectively, and the four wheels 3 are installed on the rotating shafts of the four wheel frames 2 respectively. The sixth servo motors 12 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com