Collection and dust removal device implemented by concave cavity on water hammer pavement under assistance of rolling brush

A technology of a dust removal device and a water spray device, which is applied in road cleaning, construction, cleaning methods, etc., can solve the problems of difficult dust collection and inability to completely remove road dust, etc., so as to improve the road cleaning effect and improve the utilization of water resources. efficiency, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

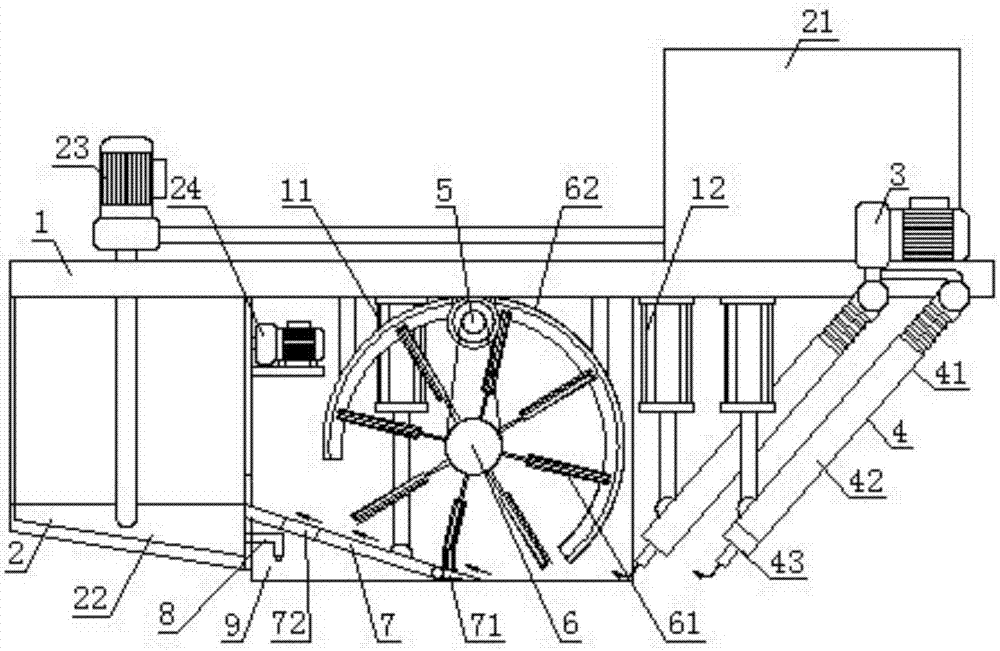

[0042] Such as figure 1 As shown, the present invention includes a rack 1, a water storage system 2 and a water pump 3 are respectively installed on the rack 1, and the water storage system 2 includes a clean water tank 21 and a sewage recovery tank 22 respectively installed on the rack 1. The clean water tank 21 Connected to the water inlet of the water pump 3, a number of water spray devices 4 for spraying water on the road are installed on the frame 1, and a number of water spray devices 4 are stacked on top of each other, and the water outlet of the water pump 3 is connected to the water spray device 4; A motor 5 is fixed on the upper part. The output shaft of the motor 5 is connected with a runner 6 through a belt drive. The runner 6 is mounted on the frame 1 through a bearing. A number of dust removal medium water collection brushes 61 are provided on the runner 6; a sewage recovery tank 22 A deflector 7 is installed on the deflector 7, the end of the deflector 7 is hinged...

Embodiment 2

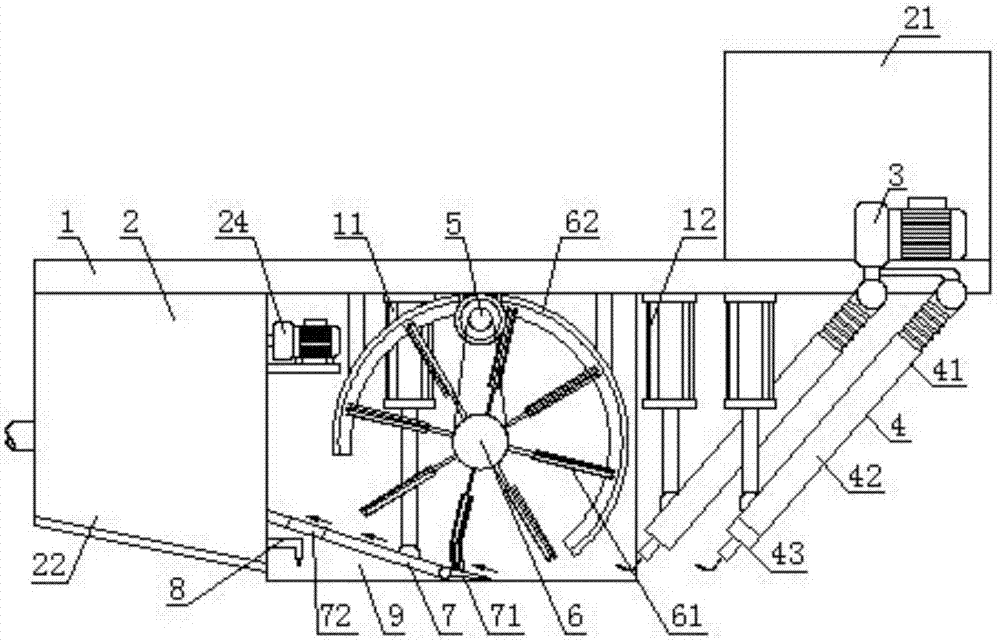

[0051] Such as figure 2 As shown, the present invention includes a rack 1, a water storage system 2 and a water pump 3 are respectively installed on the rack 1, and the water storage system 2 includes a clean water tank 21 and a sewage recovery tank 22 respectively installed on the rack 1. The clean water tank 21 Connected with the water inlet of the water pump 3, the sewage recovery tank 22 is provided with a sewage outlet, the frame 1 is equipped with a number of water spray devices 4 for spraying water on the road surface, and the water spray devices 4 are stacked on top of each other, and the water outlet of the water pump 3 Connected with the water spray device 4; a motor 5 is fixed on the frame 1, and the output shaft of the motor 5 is connected with a runner 6 through a belt drive. The runner 6 is mounted on the frame 1 through a bearing. The runner 6 is provided with a number of dust collectors Medium water collection brush 61; a deflector 7 is installed on the sewage r...

Embodiment 3

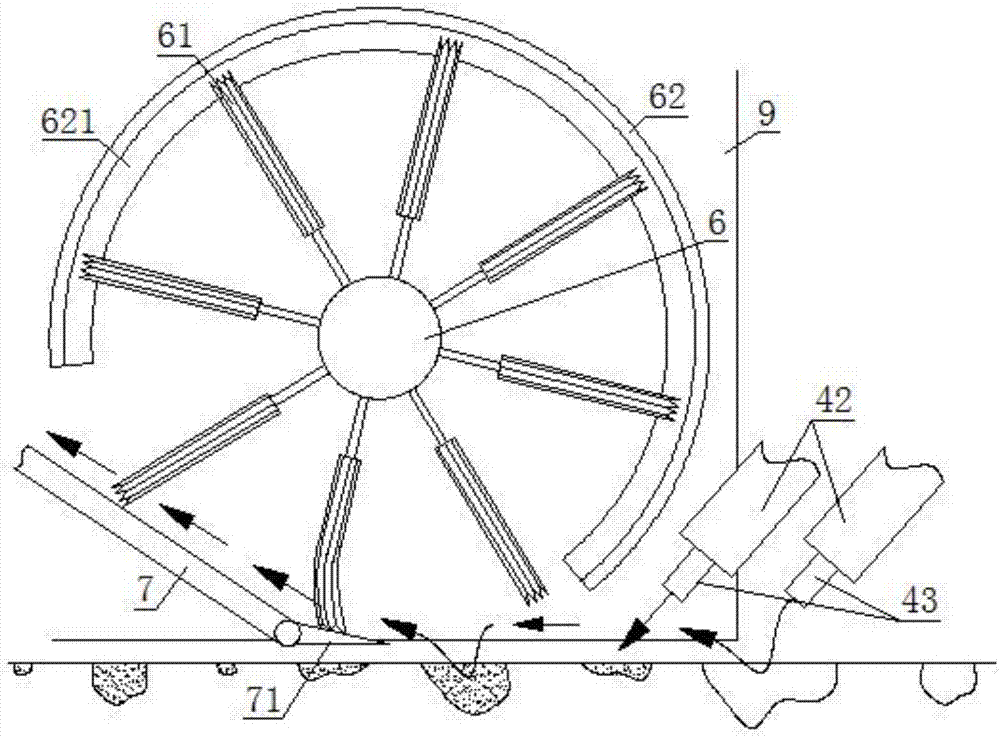

[0060] On the basis of the first or second embodiment, the frame 1 is also fixed with a runner shell 62, the runner shell 62 is sleeved outside the runner 6, and the runner shell 62 is provided with water for collecting dust removal medium. The sewage thrown by the brush 61 is collected and re-transmitted to the diversion groove 621 of the road surface.

[0061] When the runner rotates, part of the sewage on the dust removal medium water collection brush 61 will be collected by the water storage system 2, and the excess water on the dust removal medium water collection brush 61 will be thrown into the diversion groove 621 of the runner shell 62 due to centrifugal force , And is transported by the diversion groove 621 to the dust-removing medium water collection brush 61 contacting the road surface again for reuse, which improves the utilization rate of water resources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com