Pressurized propulsion tool for horizontal well

A technology for horizontal wells and tools, applied in drilling equipment and methods, rotary drilling rigs, construction, etc., can solve the problems of difficult feeding and decompression of the drill string in the horizontal section, and achieve the effects of simple and reliable control and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

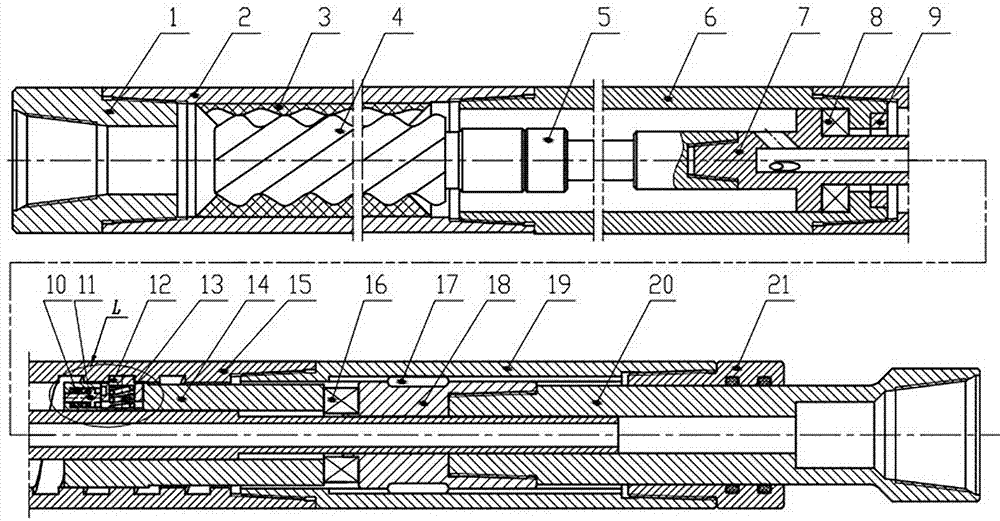

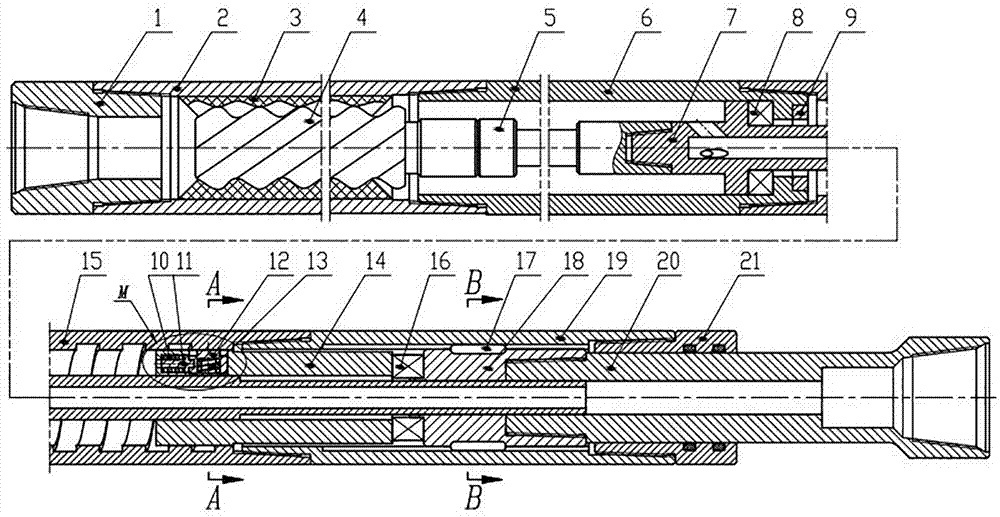

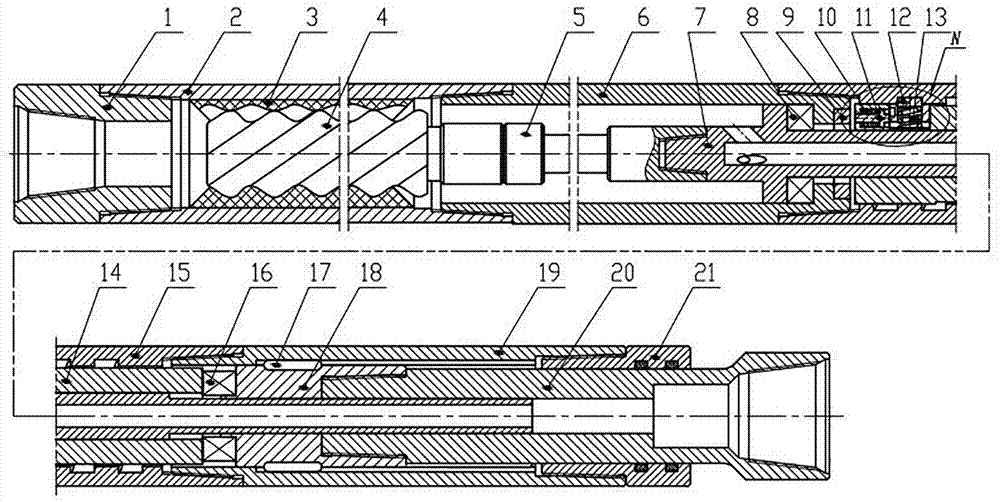

[0018] Such as figure 1 , figure 2 and image 3 As shown, a horizontal well pressurization propelling tool of the present invention is composed of an upper joint 1, a stator housing 2, a rubber stator 3, a screw rotor 4, a cardan shaft 5, a cardan shaft housing 6, a central tube 7, an adjusting Core bearing 8, magnetic ring 9, spring a10, locking pin 11, slide block 12, spring b13, push cylinder 14, spiral cylinder 15, thrust bearing 16, slide pin 17, bearing housing 18, outer casing 19, output shaft 20 and The anti-drop cap 21 is composed of; its structural features are: the upper joint 1 is connected with the upper drill string screw, the output shaft 20 is connected with the lower drill string screw; the rubber stator 3 is fixed in the inner cavity of the stator housing 2, and the screw rotor 4 is inserted The inner cavity of the rubber stator 3; the upper end of the stator housing 2 is connected with the lower end of the upper joint 1 with screws, the lower end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com