Patents

Literature

63results about How to "Realize dynamic compensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic load-variable multi-variable control method for air separation device

InactiveCN102520615ARealize decoupling controlRealize dynamic compensationAdaptive controlAir separationNonlinear control

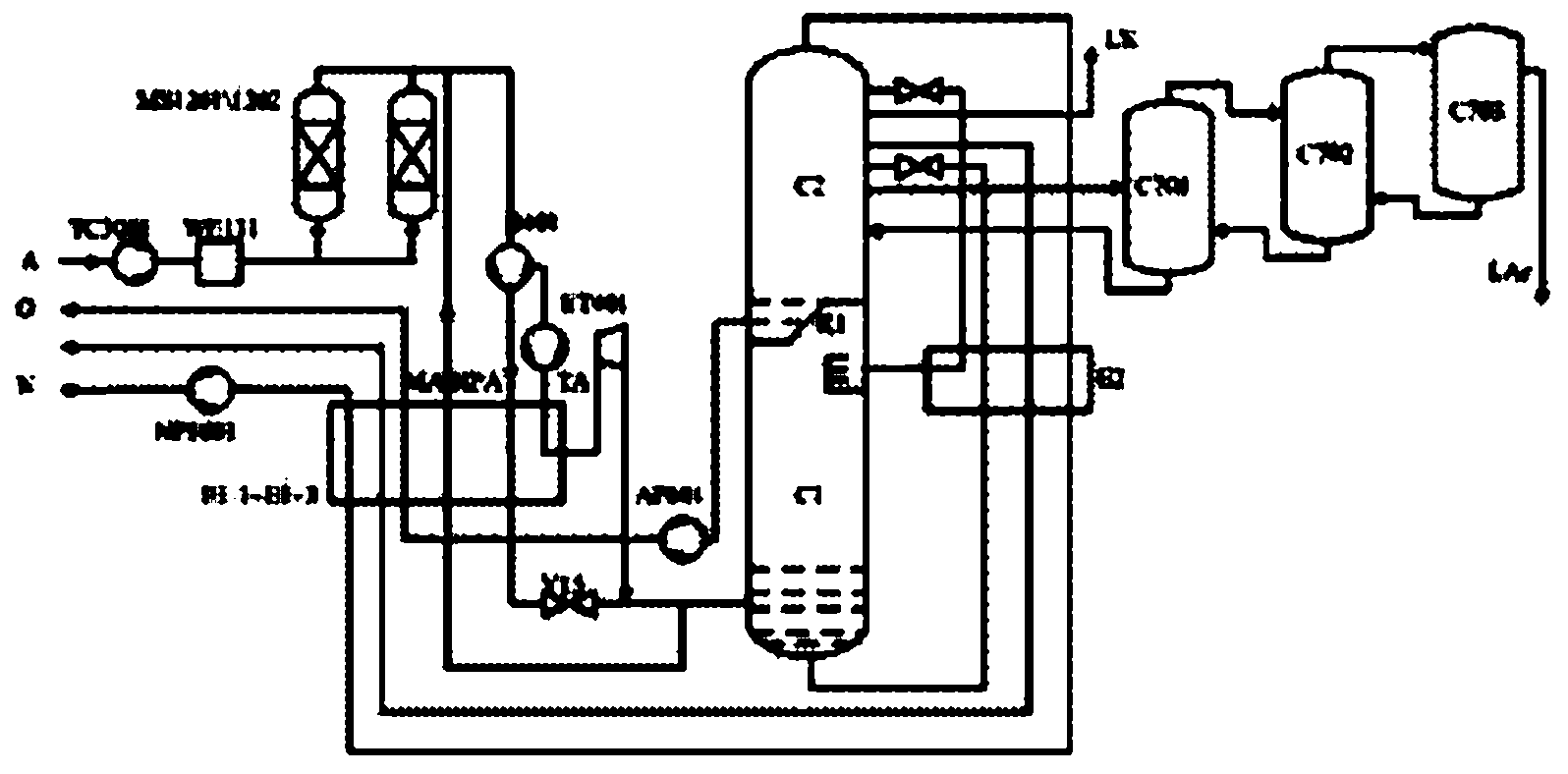

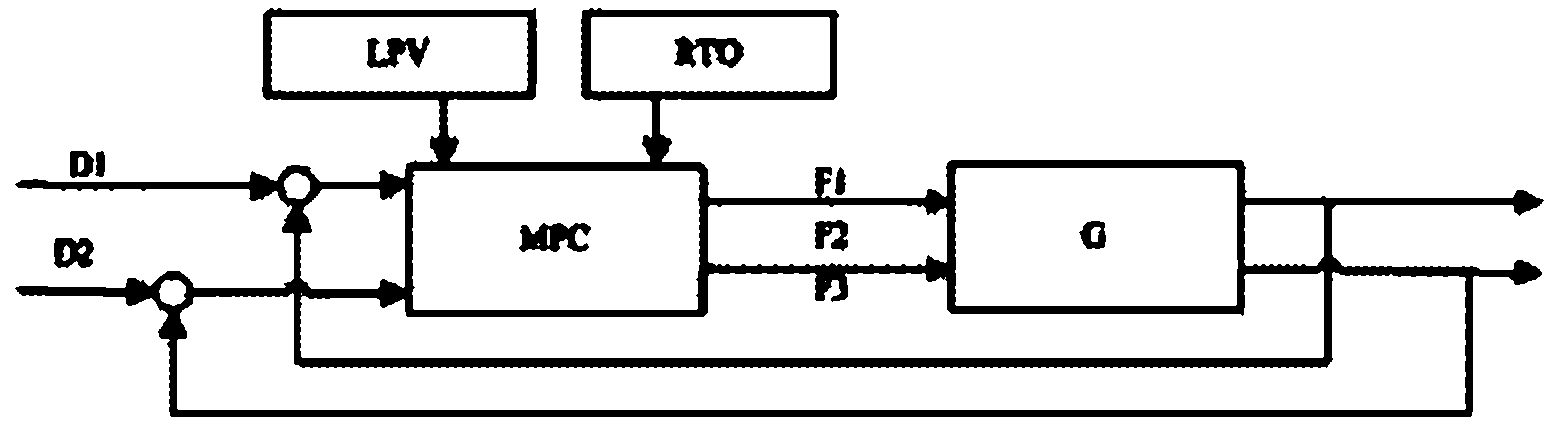

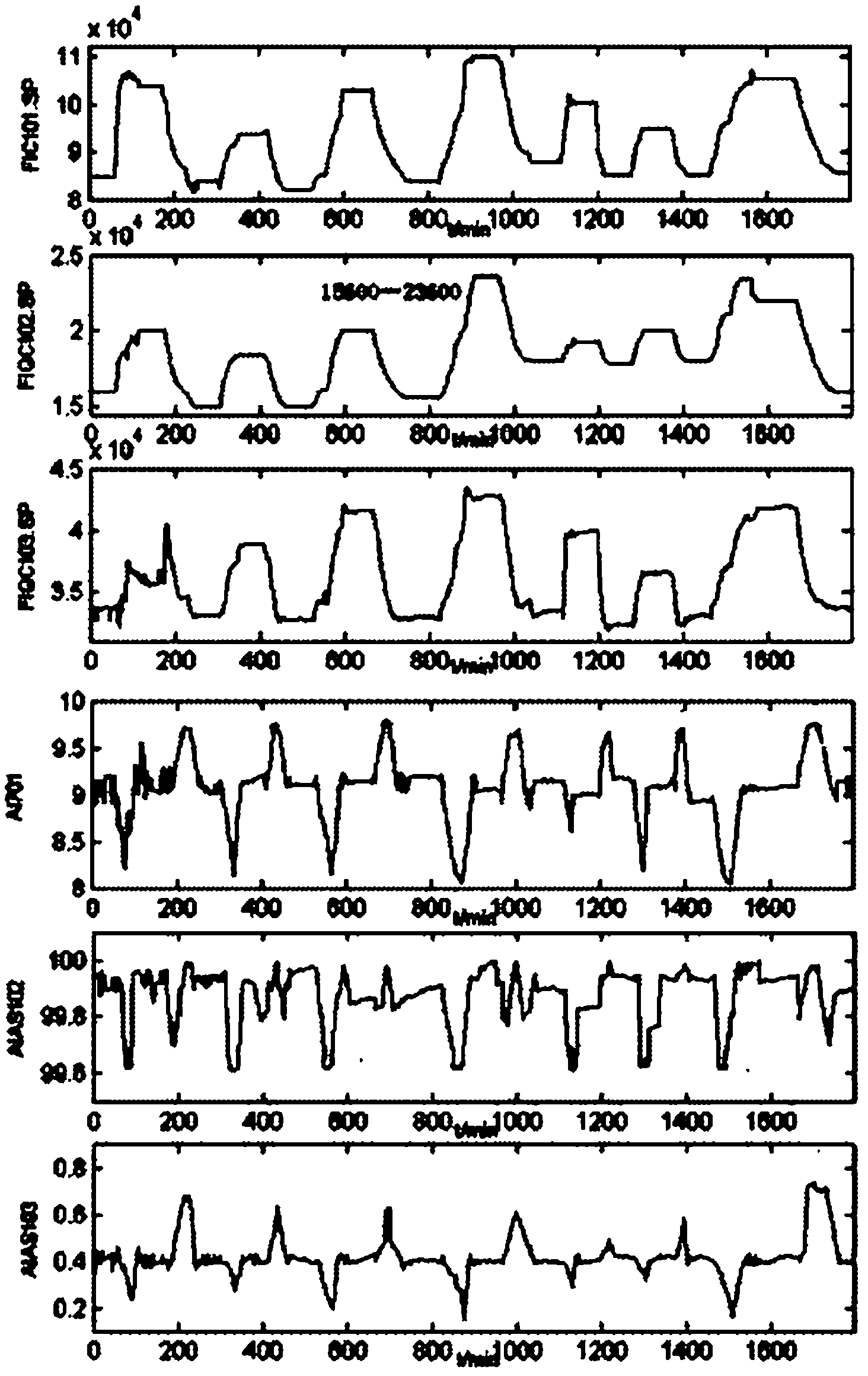

The invention discloses an automatic load-variable multi-variable control method for an air separation device. According to the method, a module 1, namely a gain scheduling module, a module 2, namely a dynamic multi-variable model prediction control module, and a module 3, namely a process real-time optimization module are involved. The method comprises the following steps that: the module 3 calculates the optimal steady state value of a process variable related to load change according to the load-variable requirement of the device and sends the optimal steady state value to the module 2; the module 1 determines a prediction model adopted by a controller of the module 2 at the moment according to the current value of a scheduling variable; and the module 2 gradually pushes the device to the optimal steady state working point which is calculated by the module 3 on the premise of ensuring product quality and not going against equipment constraints. By the method, the problems of mutual decoupling of energy and a material, nonlinear control and the like in the wide-range load-variable process of the air separation device can be radically solved, smooth and quick transition among different working conditions is realized, and the load-variable operation quality and speed of the air separation device are ensured.

Owner:DONGFANG TURBINE CO LTD +1

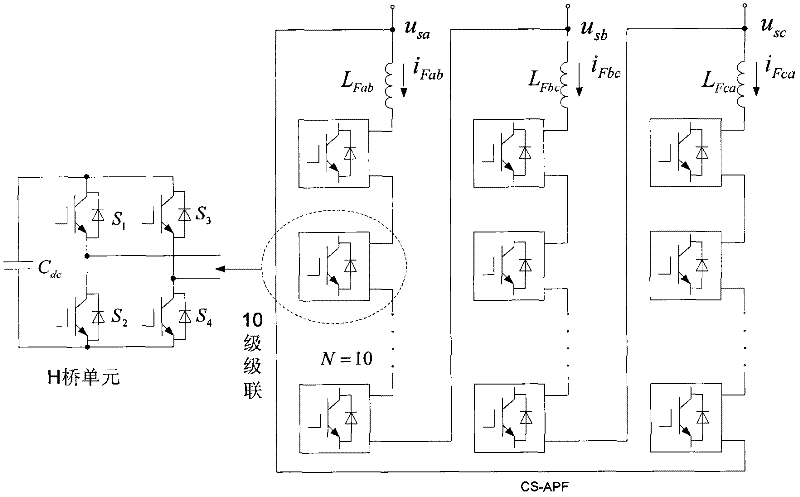

Triangular connection type comprehensive compensation system integrated with cascaded active filter and reactive compensator

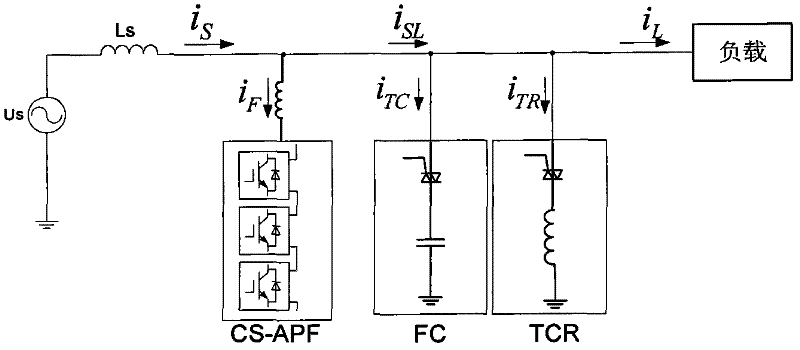

InactiveCN102545235AImprove efficiencyRealize dynamic compensationFlexible AC transmissionActive power filteringCascade converterEngineering

The invention discloses a triangular connection type comprehensive compensation system integrated with a cascaded active filter and a reactive compensator. The system comprises triangular connection type N-grade cascaded converters and a three-phase filter inductor connected with each N-grade cascaded converter; triangular connection type thyristor reactors and star-shaped connection type thyristors are used for switching the reactive compensator composed of fixed capacitors; and the triangular connection type N-grade cascaded converters and the reactive compensator are connected in parallel between a connection node and a ground node of an input power grid voltage and a load. According to the system provided by the invention, reactive power and harmonic current in a medium-voltage power grid are subjected to dynamic compensation and the efficiency of the power grid is improved; when the system is used for compensating, the system has no negative influences on the power grid, and has advantages of stable system, simple structure, strong stability and flexibility in compensation.

Owner:TSINGHUA UNIV +1

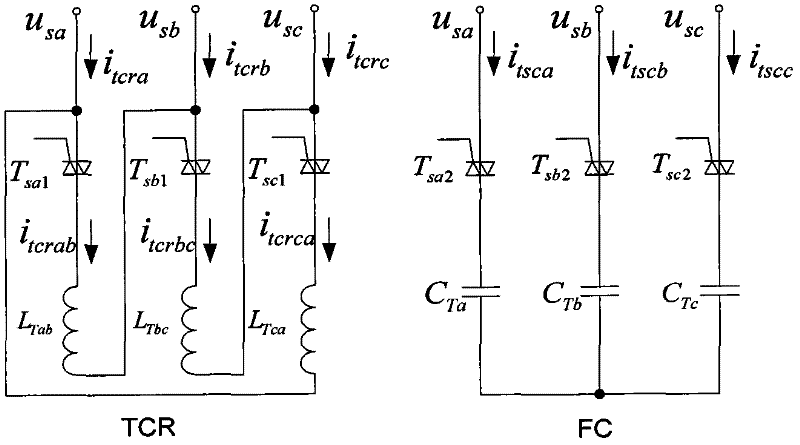

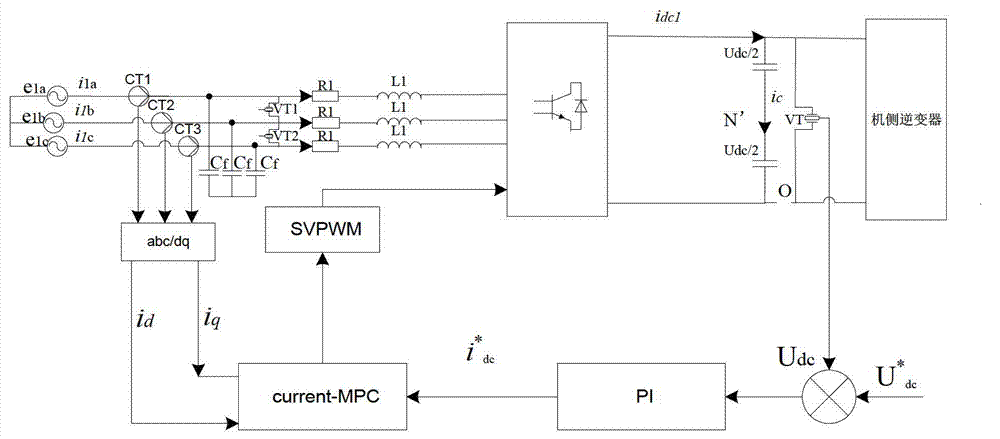

System and method for controlling doubly-fed wind power generation grid-side converter

ActiveCN103166247ARealize decoupling controlRealize dynamic compensationSingle network parallel feeding arrangementsWind energy generationPower factorEngineering

The invention discloses a system and a method for controlling a doubly-fed wind power generation grid-side converter. The system comprises a model predictive control module and a space vector modulation module. The model predictive control module controls a voltage transfer function according to dq-axis current and the dq axis of the grid-side converter, acquires a first-order difference equation of a PWM-VSR (pulse width modulation voltage source rectifier) after discretization to serve as a predictive control model and calculates control voltage of the grid-side converter in a real-time online manner by feedback correction and rolling optimization. The space vector modulation module generates a switching signal for operation of the grid-side converter according to the control voltage and controls the grid-side converter in grid-connected operation. By the aid of the system and the method, the influence of lagging of the control voltage caused by sampling delay of voltage and current of the grid-side converter can be eliminated, grid-side dq-axis current is completely decoupled, the negative influence of grid-side inductance parameters on stability and dynamic response of the system can be overcome, three-phase input current effectively tracks input power grid voltage phase, and the grid-side converter is ensured to be operated in a high power factor state.

Owner:DONGFANG TURBINE CO LTD +1

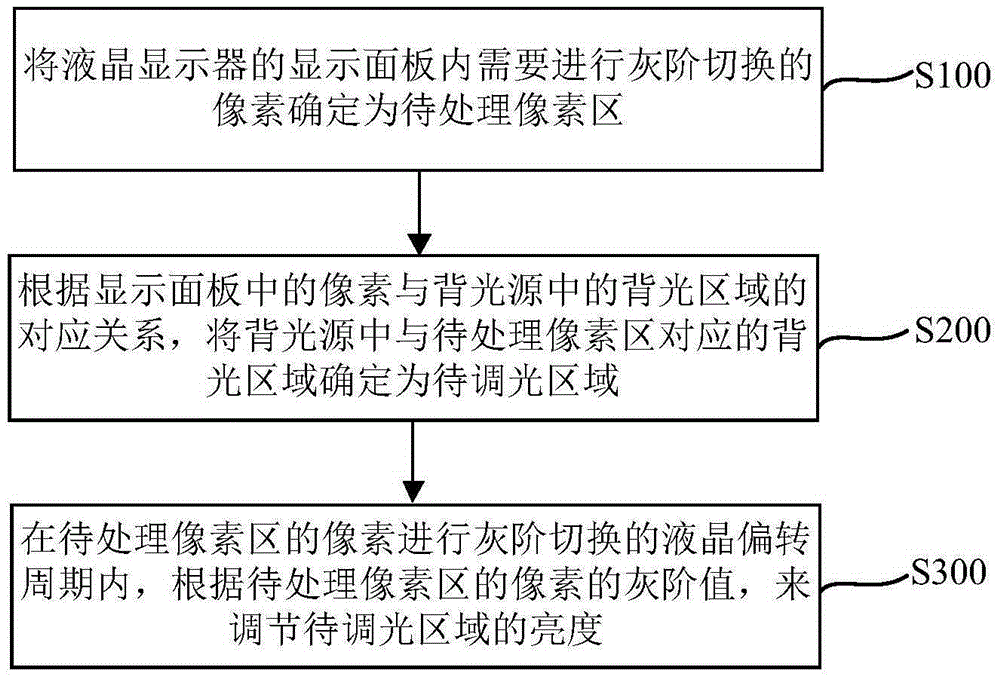

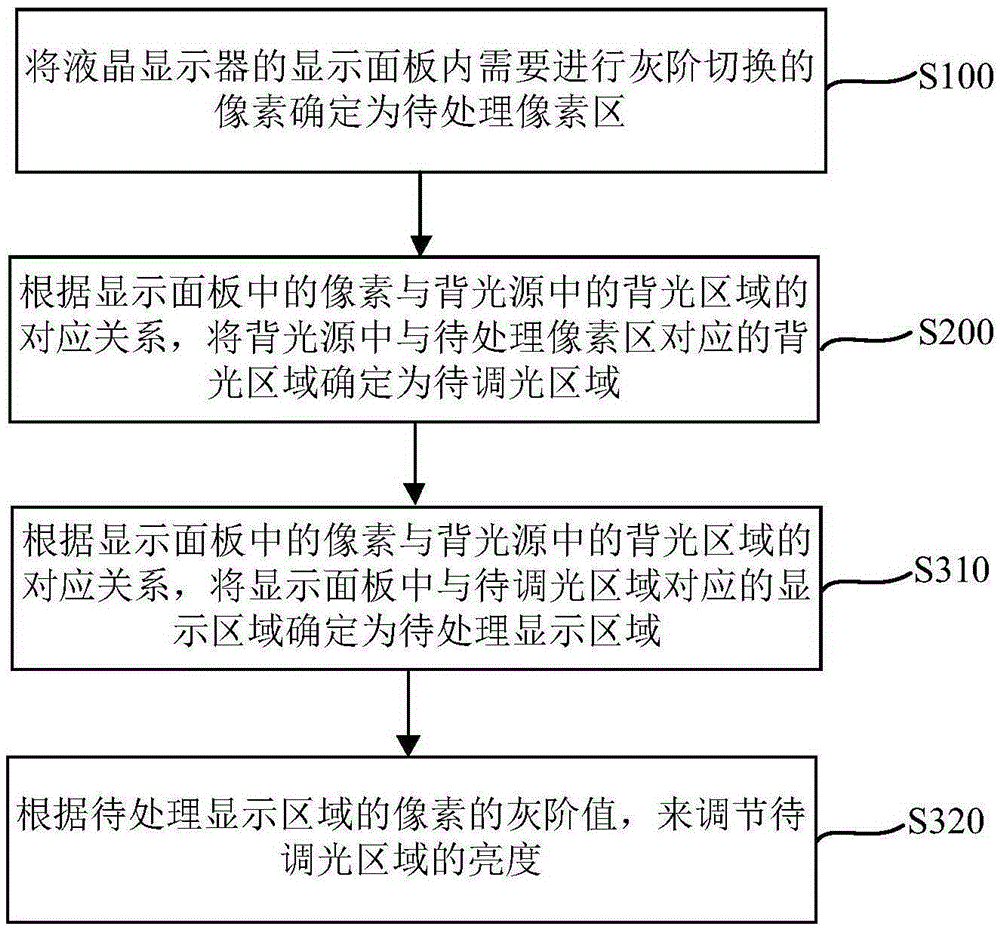

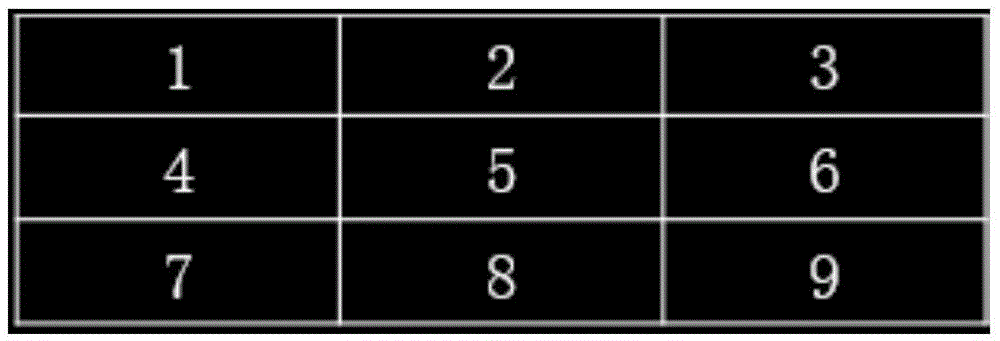

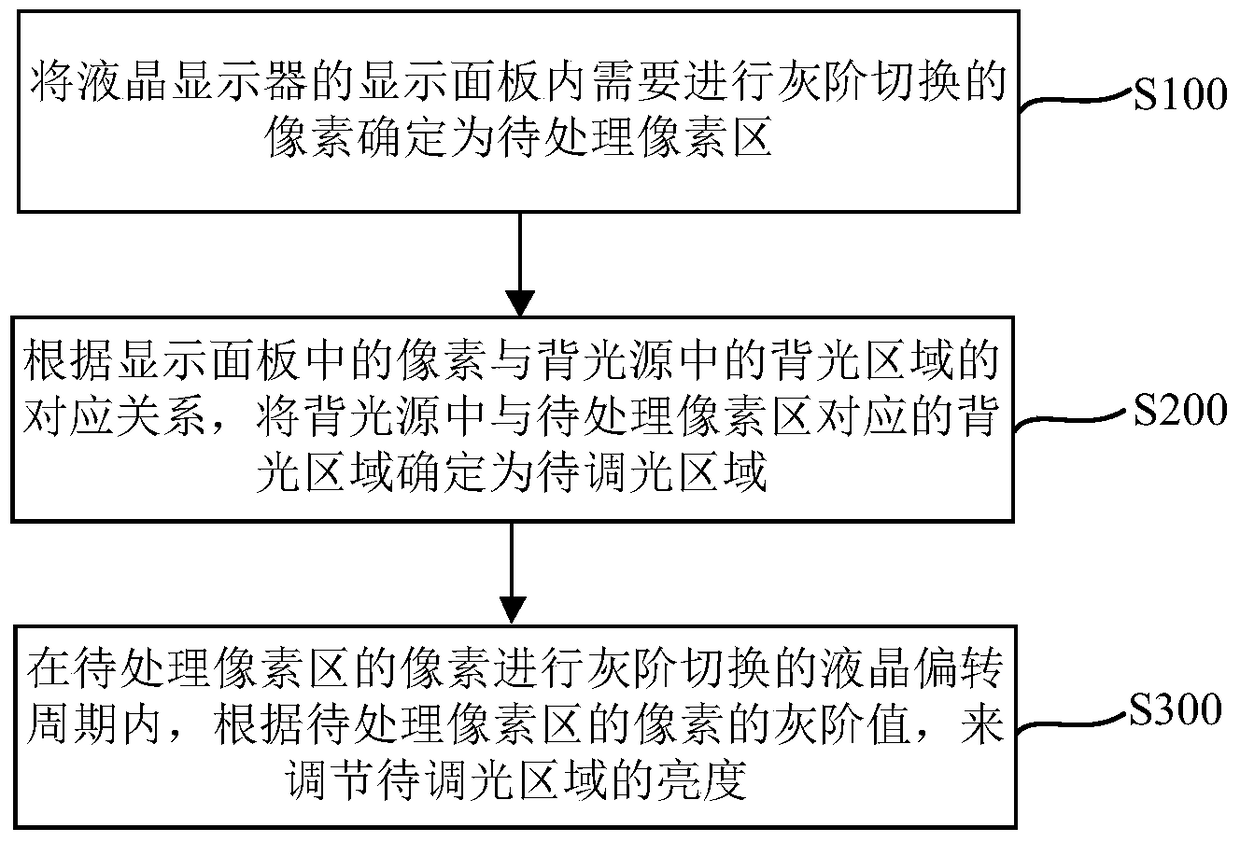

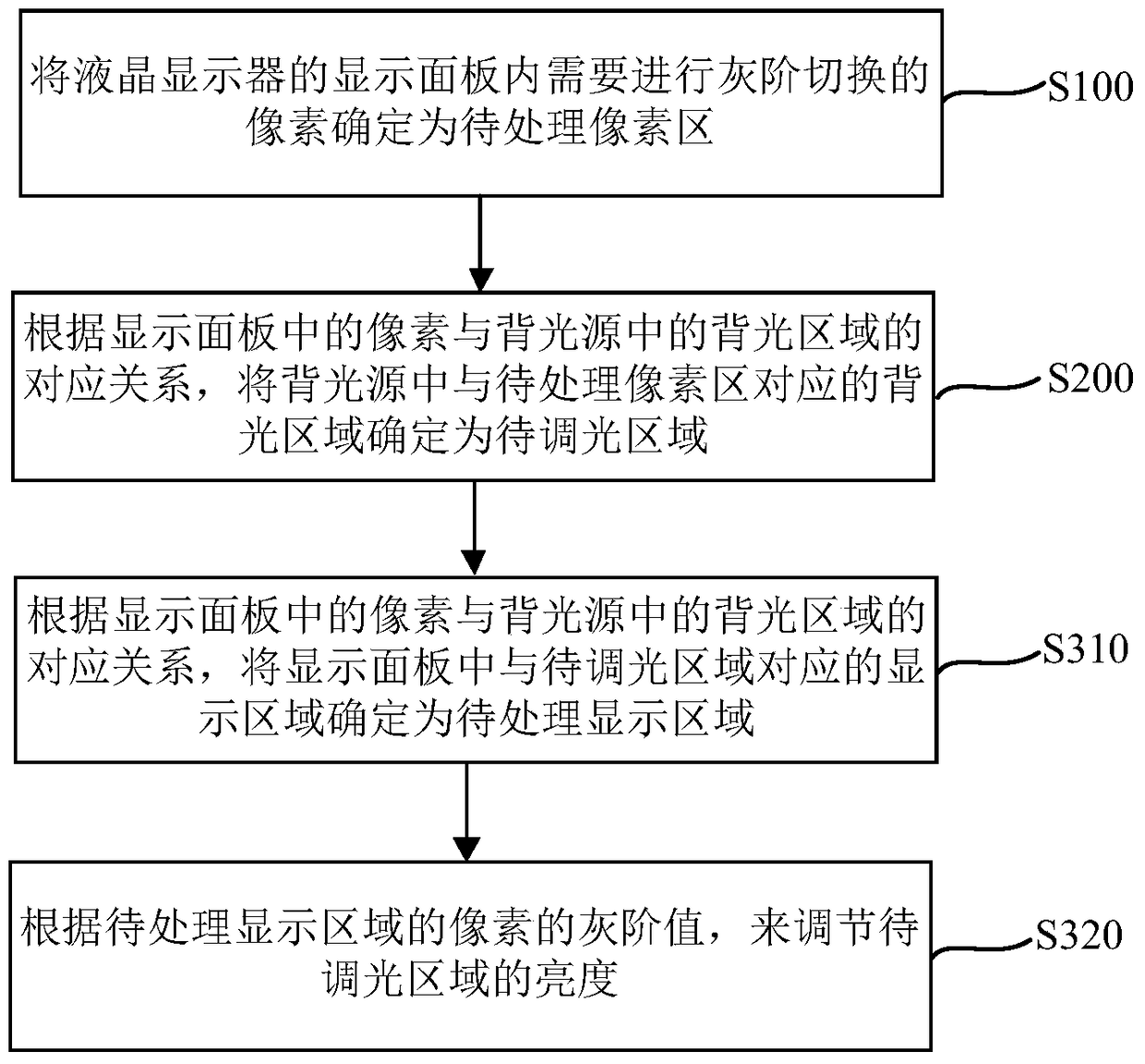

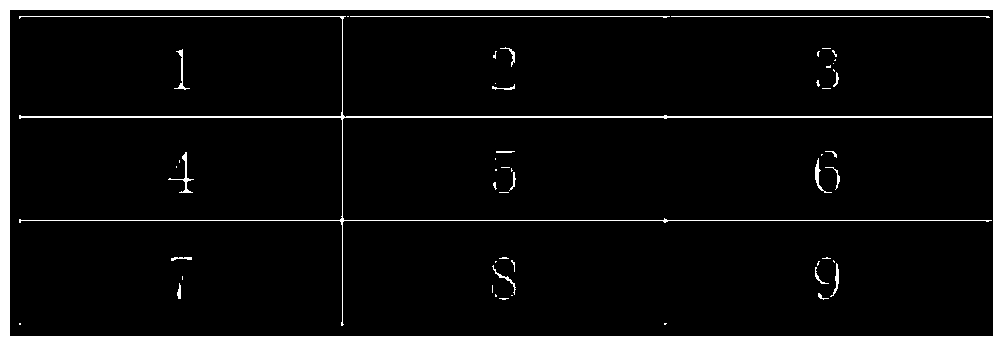

Liquid crystal display device and brightness adjusting method and apparatus thereof

ActiveCN105336298AReduces smearingConsistent brightnessStatic indicating devicesLiquid-crystal displayLiquid crystal

The invention relates to a liquid crystal display device and a brightness adjusting method and apparatus thereof. The brightness adjusting method comprises: a pixel needing to carry out gray scale switching in a display panel of a liquid crystal display device is determined as a to-be-processed pixel zone; according to a correspondence relation between the pixel in the display panel and a backlight region in a backlight source, a backlight region corresponding to the to-be-processed pixel zone in the backlight source is determined as a to-be-light-modulated region; and the brightness of the to-be-light-modulated region is adjusted according to a gray scale value of the pixel in the to-be-processed pixel zone within the liquid crystal deflection period of gray scale switching of the pixel of the to-be-processed pixel zone. According to the liquid crystal display device and the brightness adjusting method and apparatus thereof, dynamic compensation of a correlated backlight region in the backlight source can be realized, thereby reducing occurrence of a trailing phenomenon in liquid crystal display. Therefore, the brightness displayed finally on the display panel tends to be uniform, thereby realizing a good moving display effect.

Owner:ALIBABA (CHINA) CO LTD

Dynamic milling force measuring method based on tool vibration displacement

InactiveCN106563973AAccurate measurementRealize dynamic compensationMeasurement/indication equipmentsMetal working apparatusMilling cutterEngineering

The invention discloses a dynamic milling force measuring method based on tool vibration displacement, and the method improves bandwidth of a measuring system, realizes precise measurement of dynamic milling force, can carry out dynamic compensation on the measuring system, improves bandwidth of the measuring system and realizes precise measurement of dynamic milling force. In order to overcome the limitation, in dimensions of processed workpieces, quality of processed workpieces, measured bandwidth, a mounting way and the like, of an existing dynamic milling force measuring method, the invention discloses a method for indirectly determining dynamic milling force through vibration displacement by utilizing measuring radial vibration displacement of a cutter bar of a rotary milling cutter during milling processing of a laser vibration measurer according to a relationship of vibration displacement and milling force of the milling cutter, solves the measuring distortion problem of milling force at a high milling speed of the milting cutter, carries dynamic compensation for the measuring system, improves bandwidth of the measuring system, and realizes precise measurement of dynamic milling force.

Owner:GUILIN JUNWIN MECHANICAL & ELECTRICAL TECH CO LTD

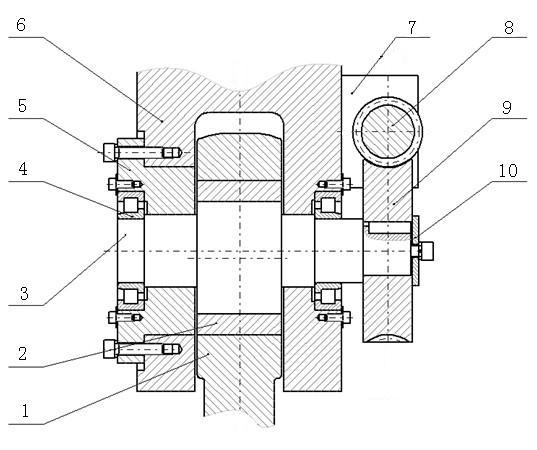

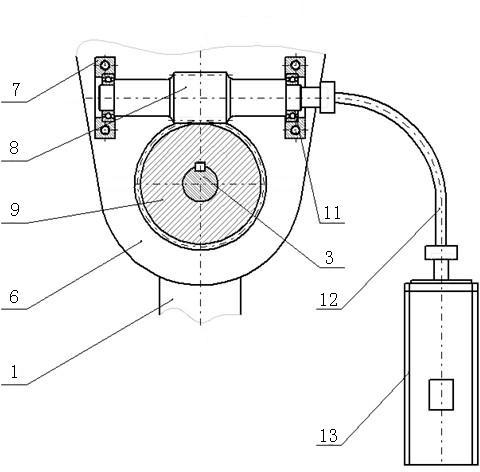

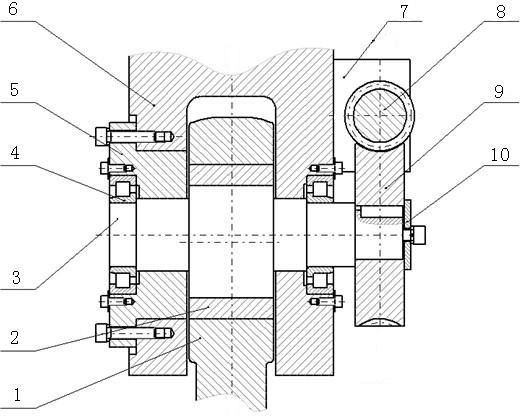

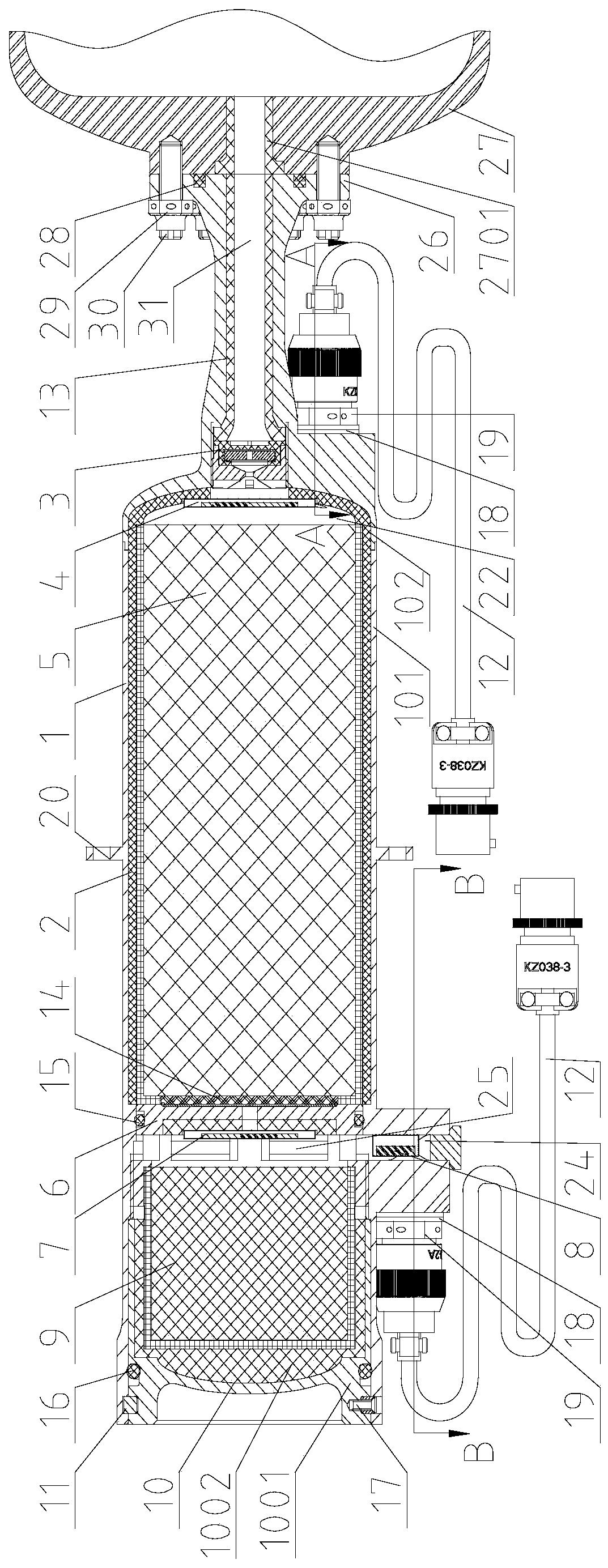

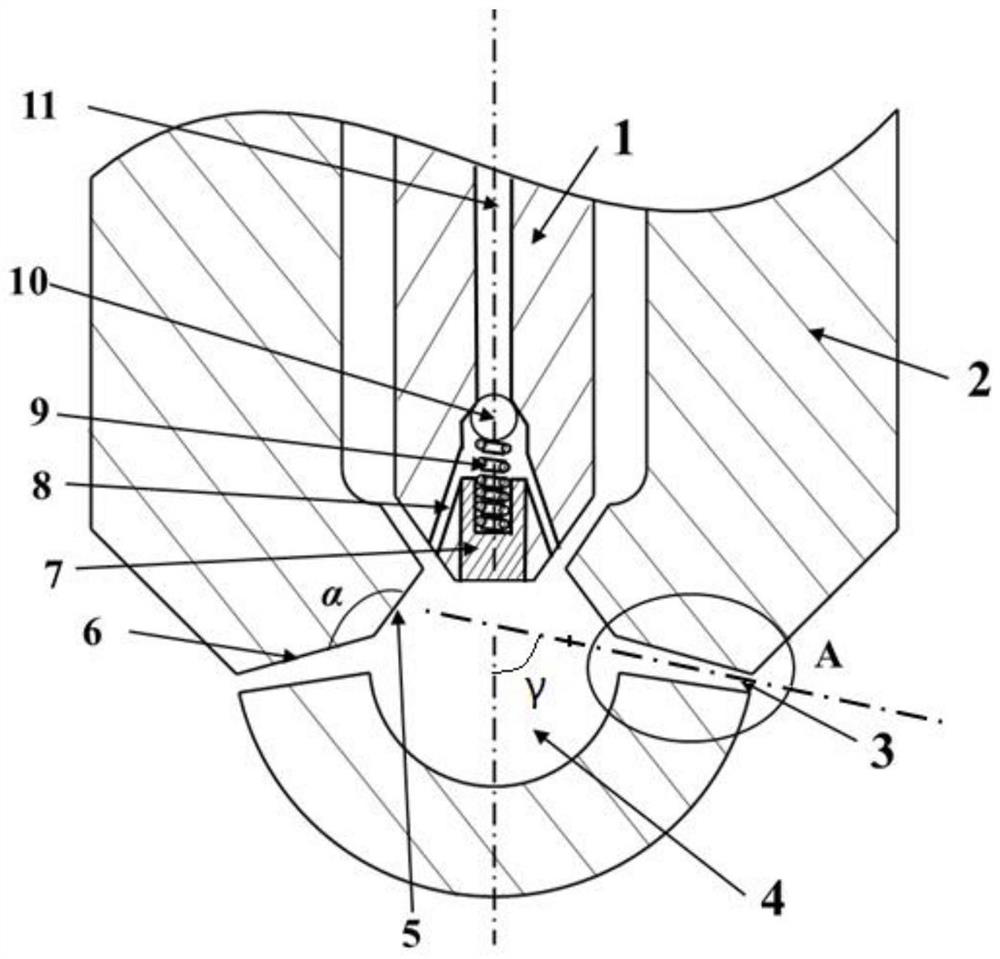

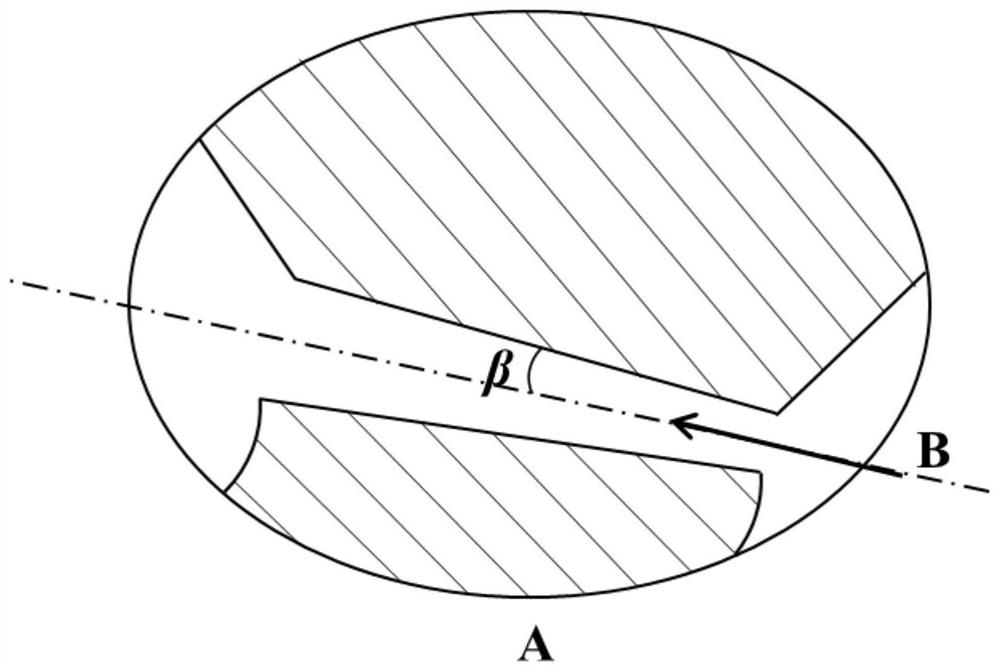

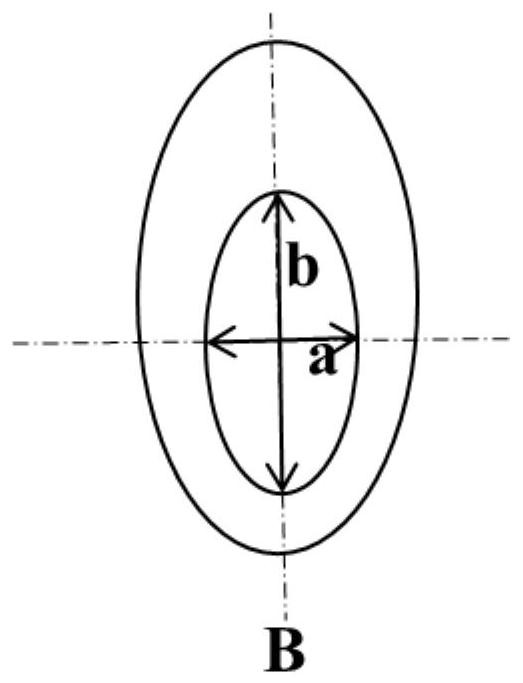

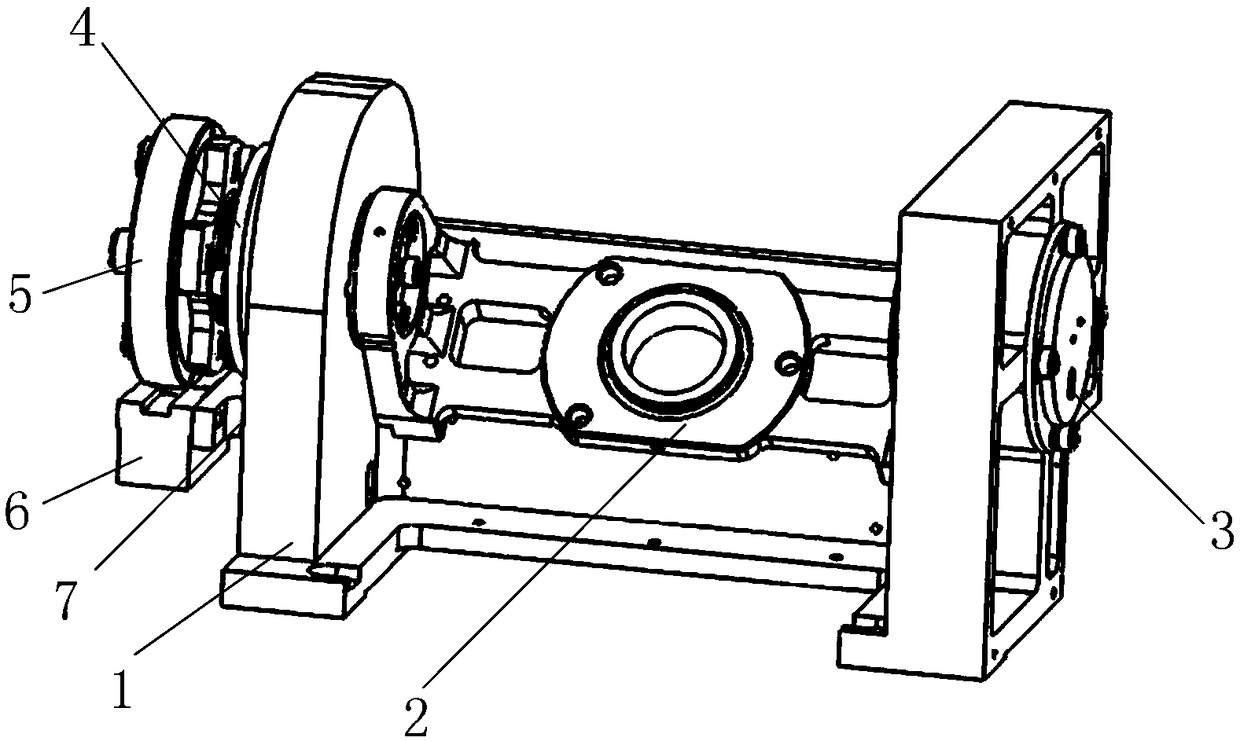

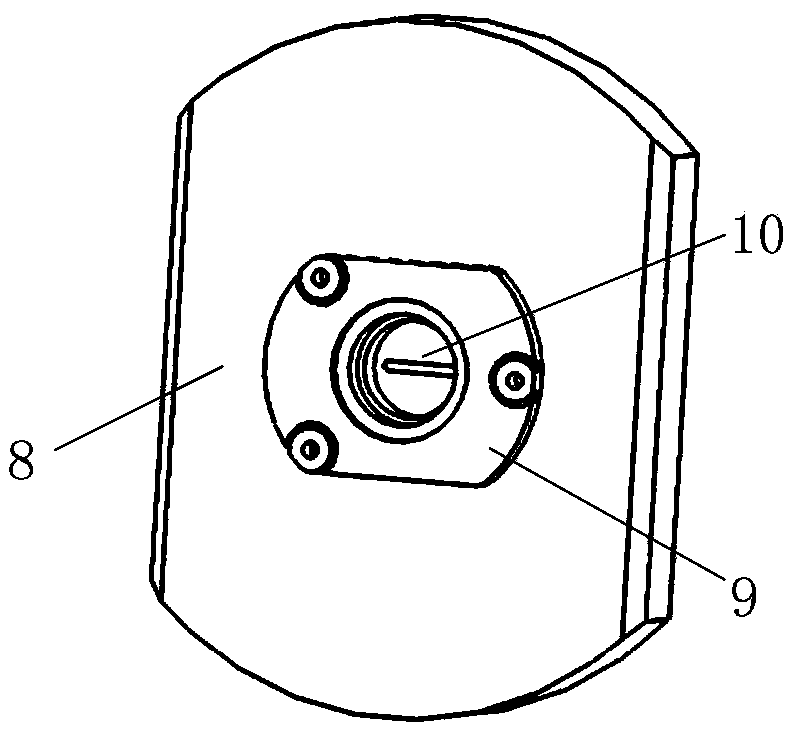

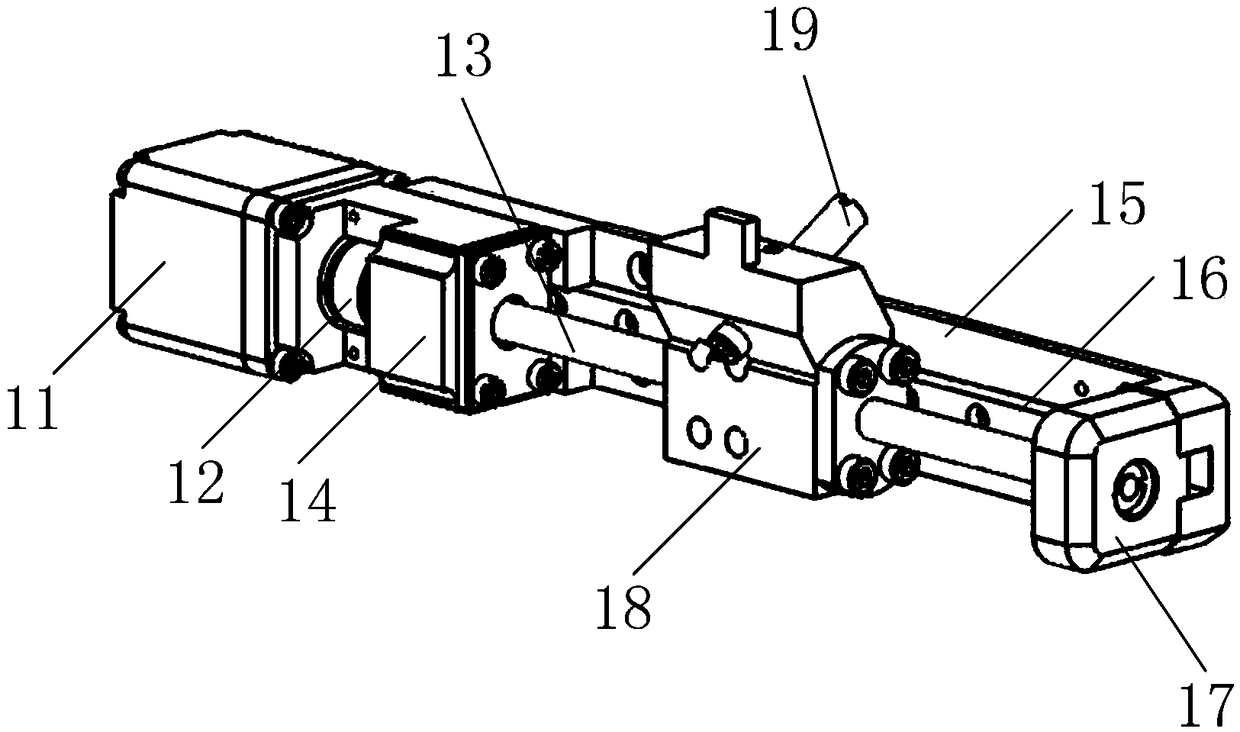

Dynamic compensation mechanism for bottom dead center of high-speed precise press

InactiveCN102602029AReduce frictional resistanceImprove carrying capacityPressesRoller bearingEngineering

The invention discloses a dynamic compensation mechanism for a bottom dead center of a high-speed precise press, which belongs to the technical field of pressure machinery. The dynamic compensation mechanism comprises a shaft which is installed on a connecting rod through two cylindrical roller bearings and a shaft seat; the shaft is a middle eccentric structure; a worm and worm wheel mechanism is arranged at one end of the shaft; a worm wheel is connected with the shaft; a worm is fastened on the connecting rod through a bearing seat and is connected with a servo motor through an elastic flexible shaft; and the servo motor is fastened on a machine body of the press. The dynamic compensation mechanism has the beneficial effects that: frictional resistance overcome during the dynamic compensation is small through a shaft support mechanism, the bearing capacity is large during the stamping, the assembly is convenient, and threads do not need to be loosened in a die-filling adjusting height of a slide block during the compensation, so that bottom dead center precision deviation of the slide block, caused by gaps among the threads is eliminated, the dynamic compensation of the bottom dead center is realized, the high stamping precision of the press is ensured, the quality of stamped parts is improved, and the service life of a mould is prolonged; at the mean time, the servo motor is directly fastened on the machine body of the press, so that the servo motor is not impacted by vibration, and the reliability of the servo motor is improved.

Owner:JIANGSU XUZHOU METALFORMING MACHINE GROUP

Human eyes high order optical aberration orthopraxy method

InactiveCN1702494AEasy to measureThe realization of convenient measurementEye diagnosticsPhotomechanical exposure apparatusResistOptical aberration

A method for correcting the higher aberration of human eyes, characterized in that it comprises the following steps: a) measuring accurately aberrations with different ranks by adopting measuring apparatus of aberration of human eyes to get the data of aberration; b) designing aberration correcting function according to the data of aberration; c) designing photoetched mask according to the function designed, then preparing mask plate according to the design; d) exposing resists by using mask plate prepared to get micro-rilievo structure made of resists after developing; e)taking microstructure as master blank, transferring the microstructure to material surface of contact lenses by adopting technique of copying. The invention is suitable for the condition of a plurality of complication existing simultaneously.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

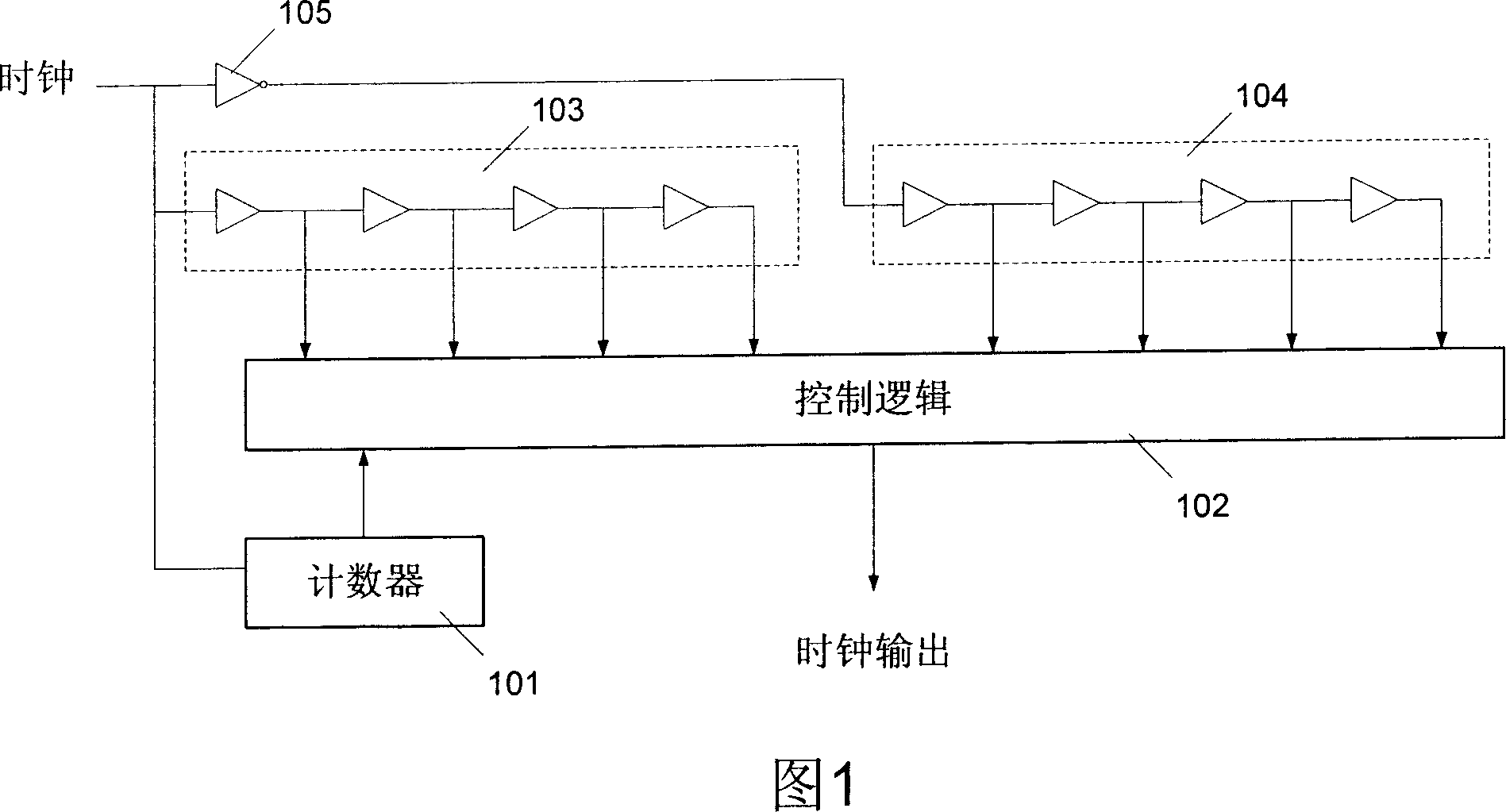

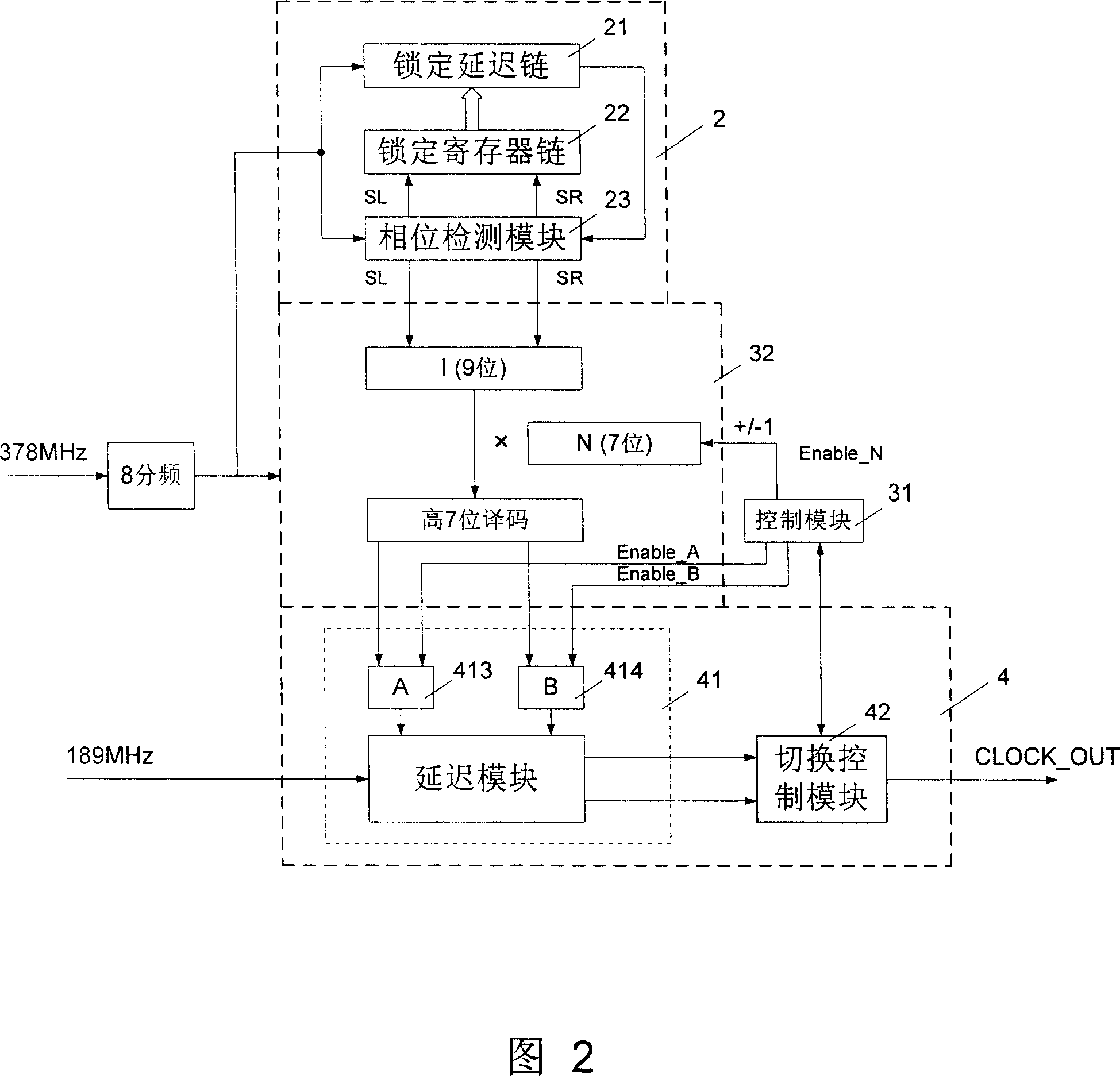

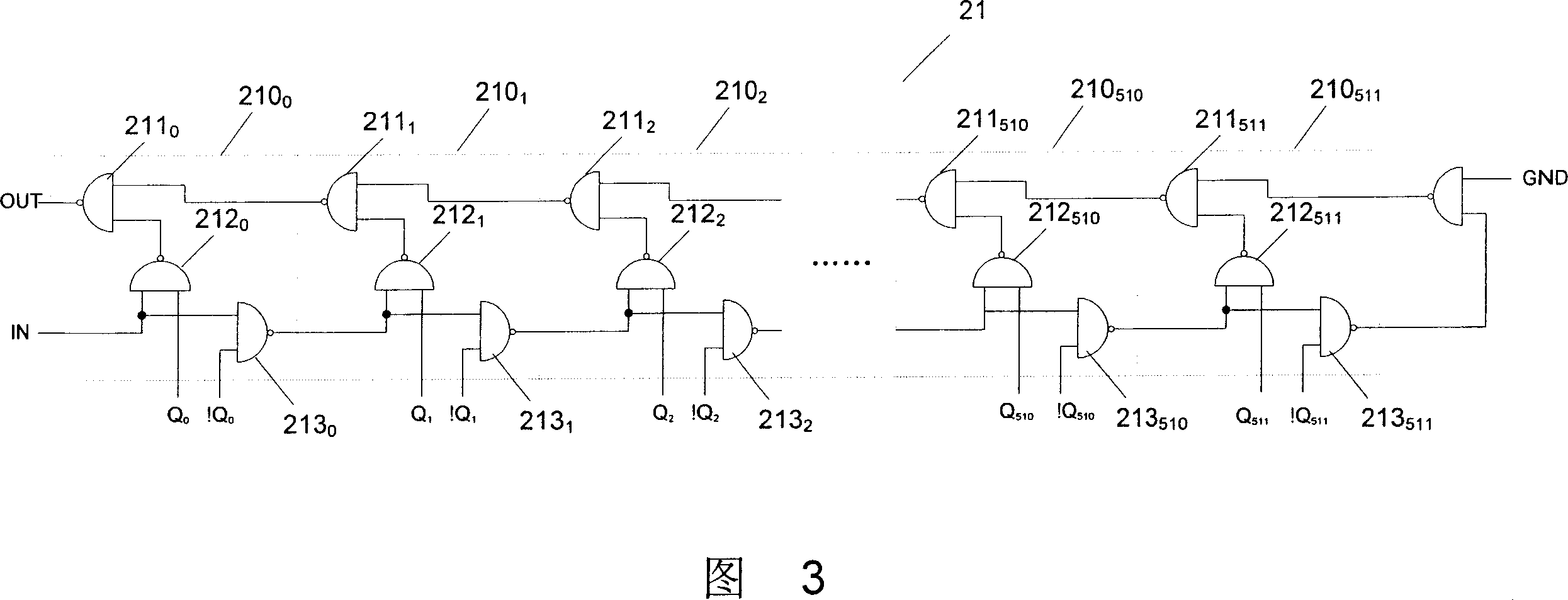

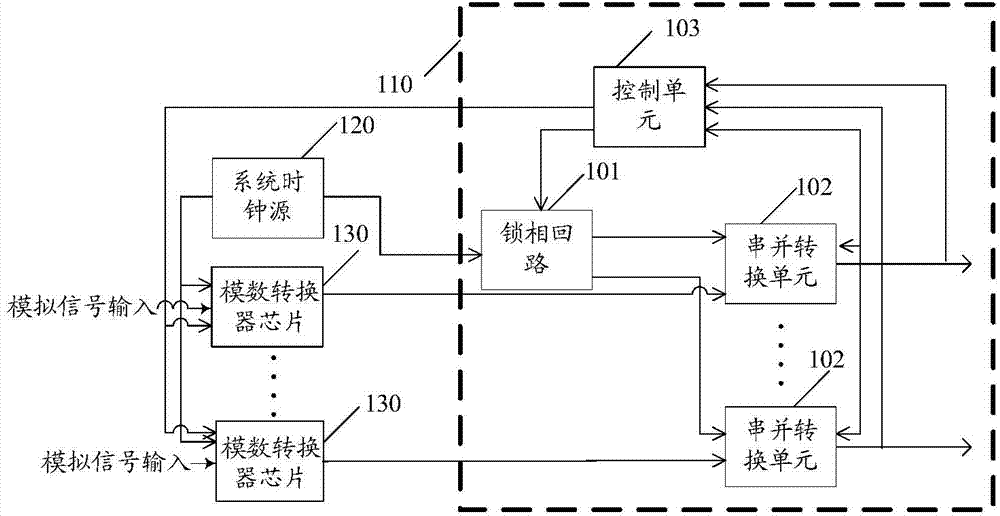

Digital phase lock loop and its clock adjusting method

InactiveCN101009483ARealize dynamic compensationAchieve regulationPulse automatic controlSingle output arrangementsComputer sciencePhase-locked loop

A digital phase-lock loop and clock adjusting method, the locking module is used to detect how many delay units are required by delaying input clock for N clock periods; calculating module which is used to calculate the number of delay unit needed by input clock based on the input of system;The clock adjusting module which adjusts the input clock based on the calculating result of the calculating module; control module which is use to control the calculating module and clock adjusting module, the clock adjusting module includes the first delay chain and the second delay chain, the corresponding delay unit is selected based on the result of the calculating module, the clock adjusting module also includes switch control module which is used to choose one output of the first delay chain and the second delay chain as the output clock, the control module controls the first delay chain and the second delay chain based on the selection of the switch control module, and loads the calculation of the calculating module to unselected delay chain.

Owner:SHANGHAI MAGIMA DIGITAL INFORMATION

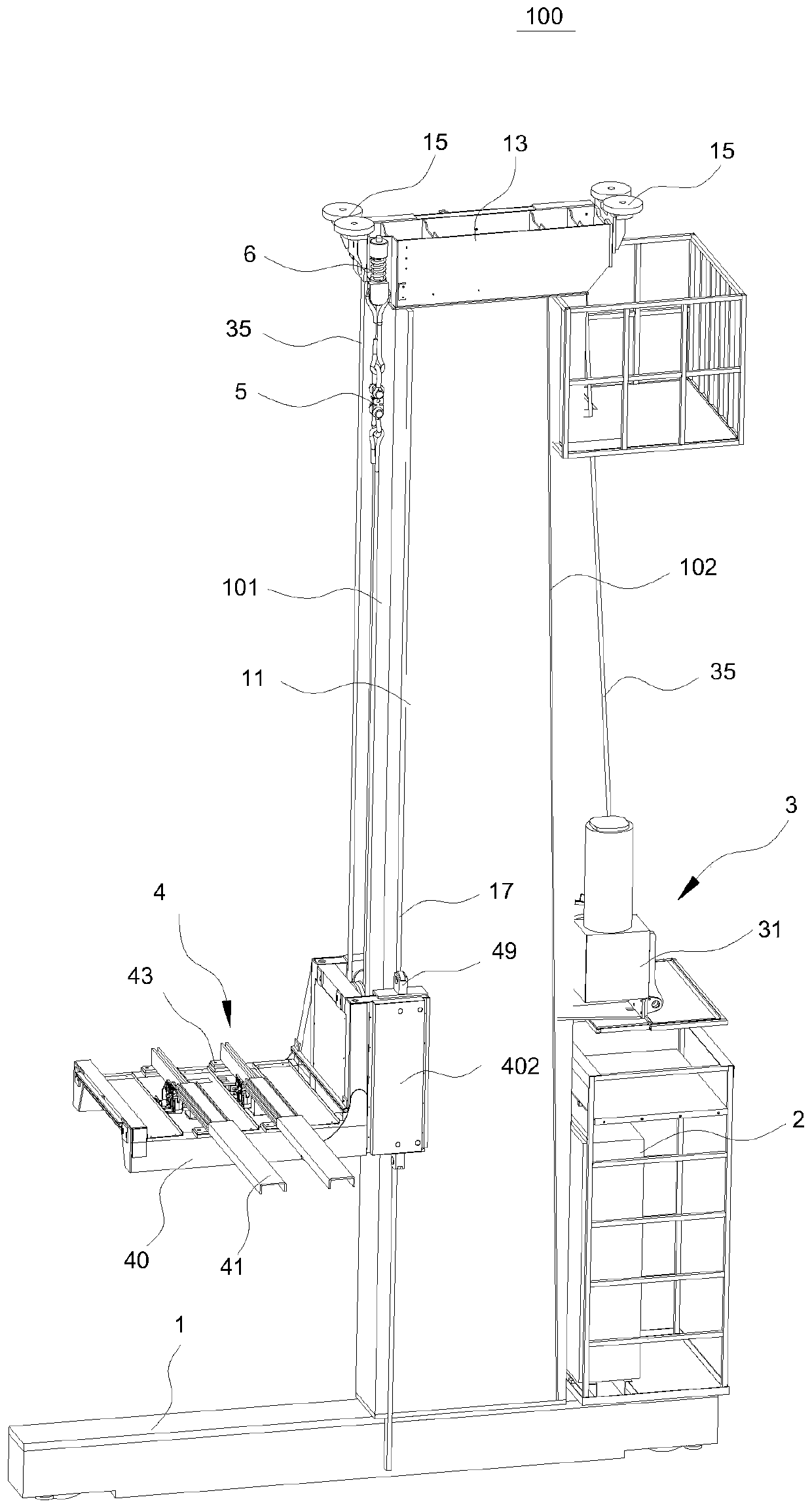

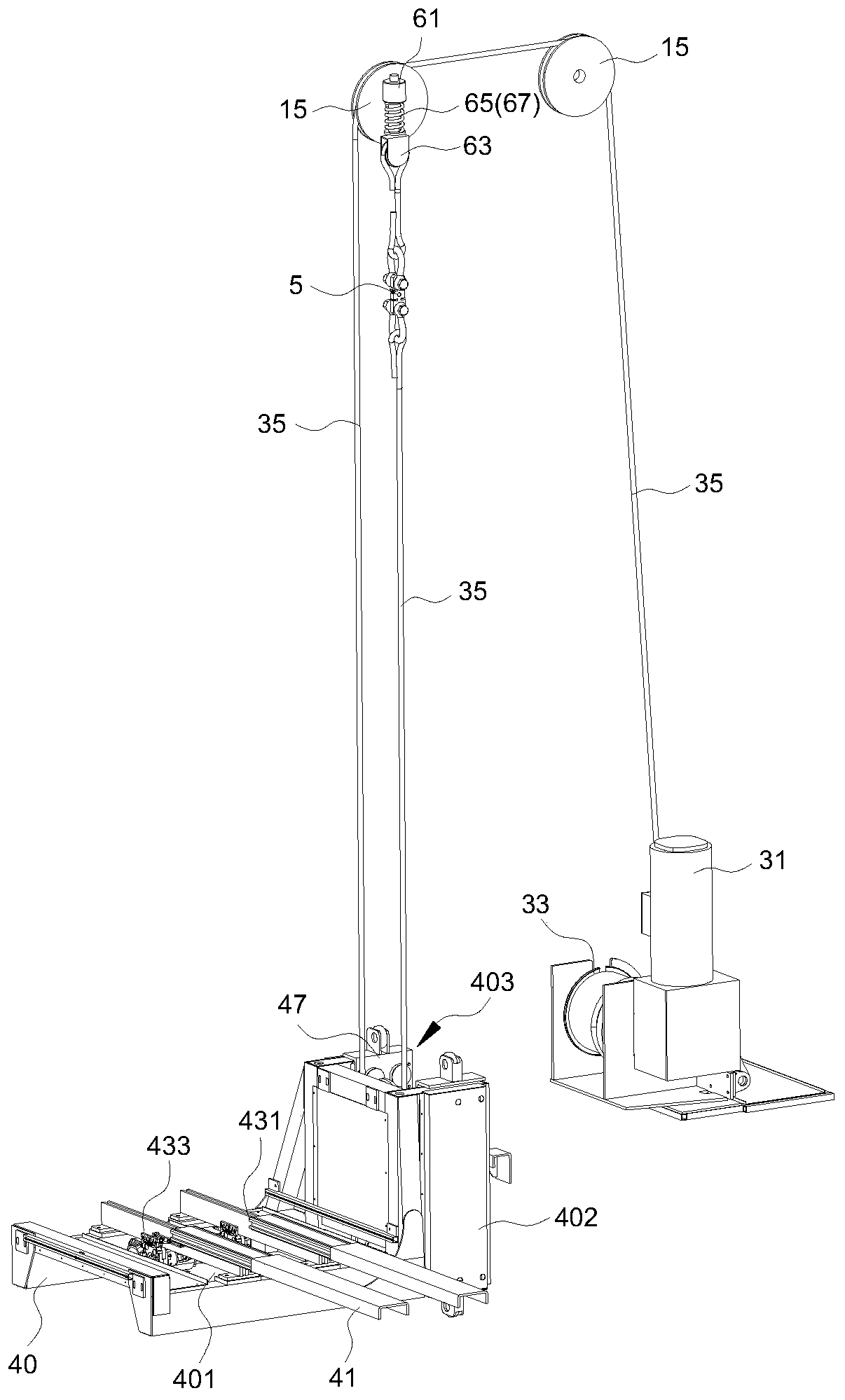

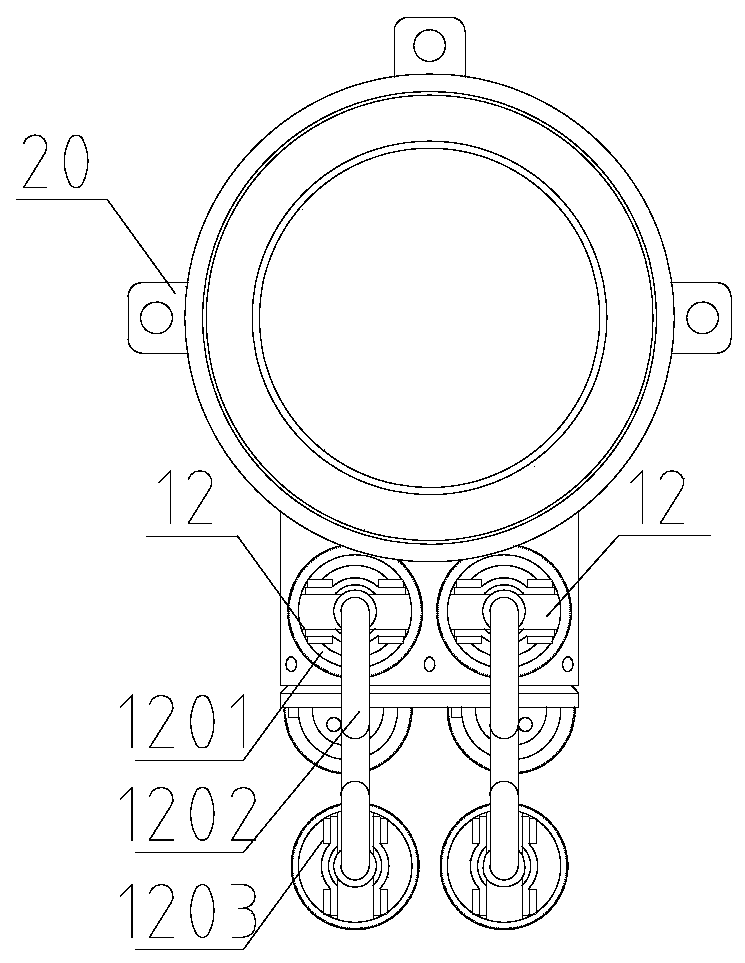

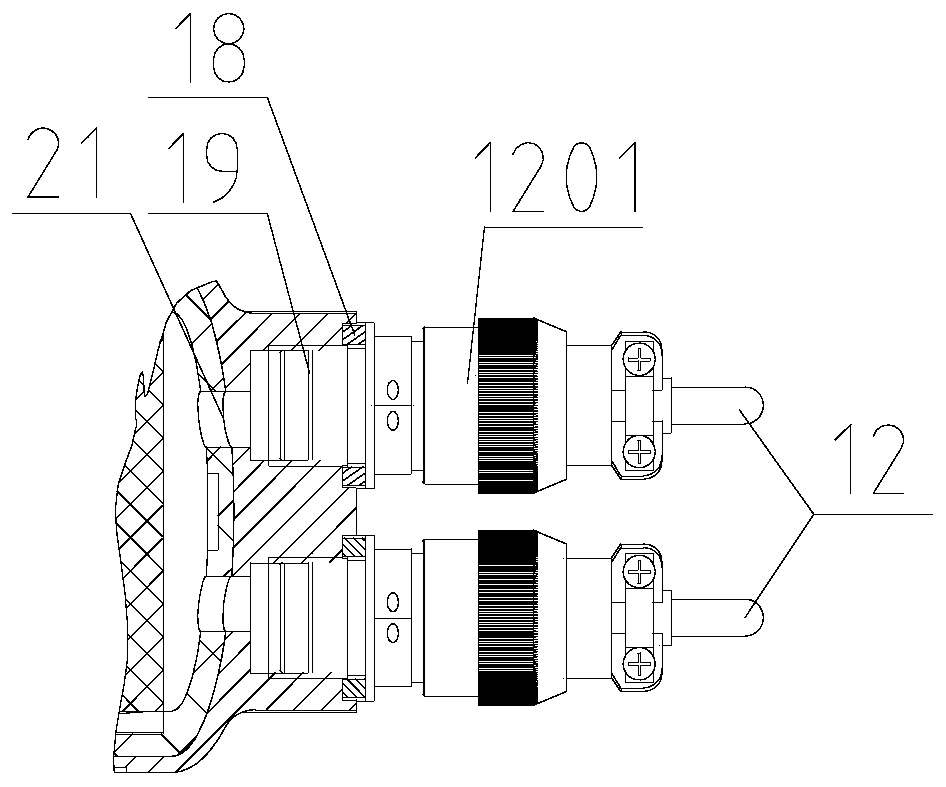

Stacking machine and fork positioning method thereof

ActiveCN111056493ASimple structureHigh precisionSafety devices for lifting equipmentsControl engineeringMachine

The invention provides a stacking machine and a fork positioning method thereof. A lifting module in the stacking machine is used for lifting a cargo carrying table, and specifically the cargo carrying table is pulled by a steel wire rope to vertically ascend and descend along stand columns; a load detection module is arranged on the steel wire rope and can detect the weight of cargos on the cargocarrying table in real time; and the controller can calculate the deformation quantity of a fork according to the weight of the cargos and then calculate the extension length, needing to be compensated for, of the fork according to the deformation quantity, so that the normal use requirement of the fork for taking and placing the cargos is met. The stacking machine is simple in structure and convenient to install, dynamic compensation for the extending length of the fork can be achieved, the positioning error of the fork is reduced, and the cargo placing precision is improved.

Owner:广东瑞仕格科技有限公司

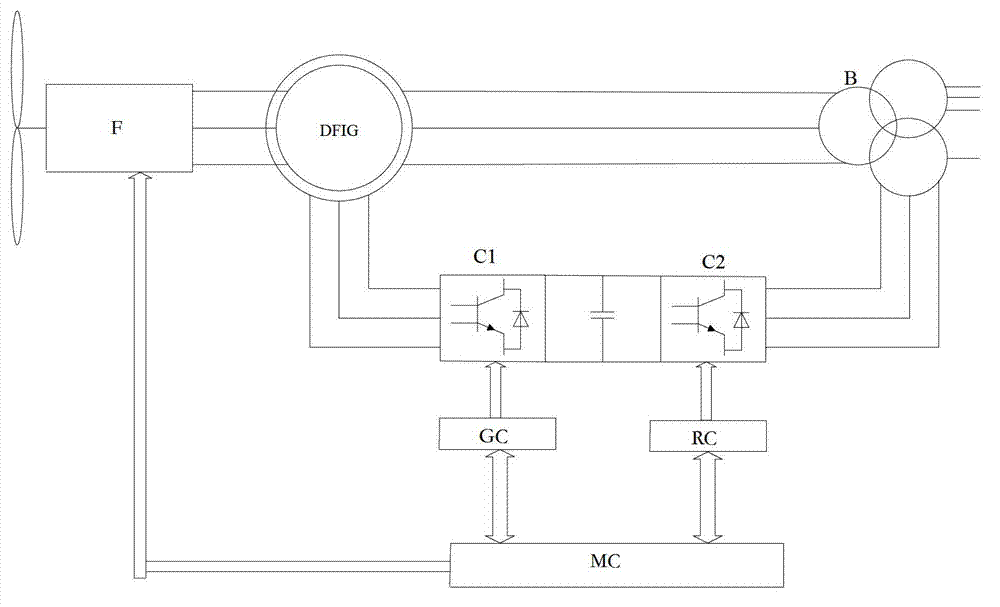

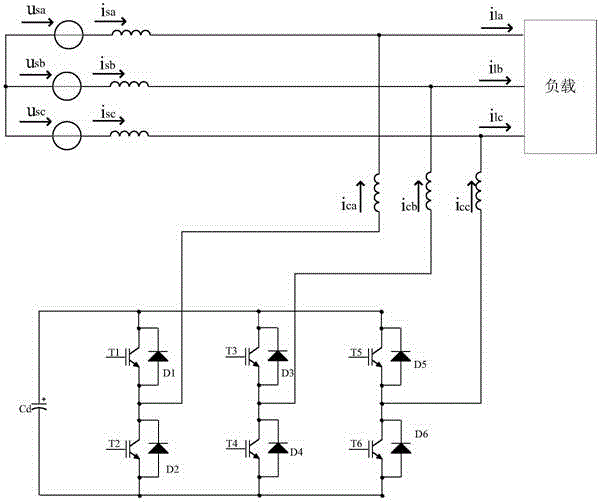

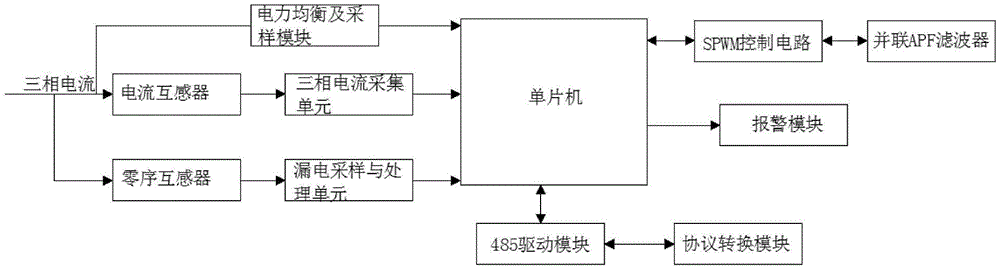

Three-phase bridge PWM converter and active power filter formed by same

InactiveCN103607133ACompensate harmonics in real timeReal-time reactive power compensationActive power filteringAc-dc conversionCapacitanceHarmonic

The invention discloses a three-phase bridge PWM converter. The three-phase bridge PWM converter comprises a first bridge arm circuit, a second bridge arm circuit and a third bridge arm circuit which have the same connecting mode. One end of each bridge arm circuit is connected with the positive electrode of a capacitor, and the other end of each bridge arm circuit is connected with the negative electrode of the capacitor. Each bridge arm circuit comprises two IGBTs which are in series connection, and each IGBT is in parallel connection with a diode. The invention further discloses an active power filter which is provided with the three-phase bridge PWM converter. By means of the three-phase bridge PWM converter and the active power filter formed by the same, harmonic waves and idle work with the variable frequency and size can be compensated, the defect of the active filter can be overcome, and the compensation characteristic better than that of the active filter can be obtained.

Owner:CSG SMART SCI&TECH CO LTD

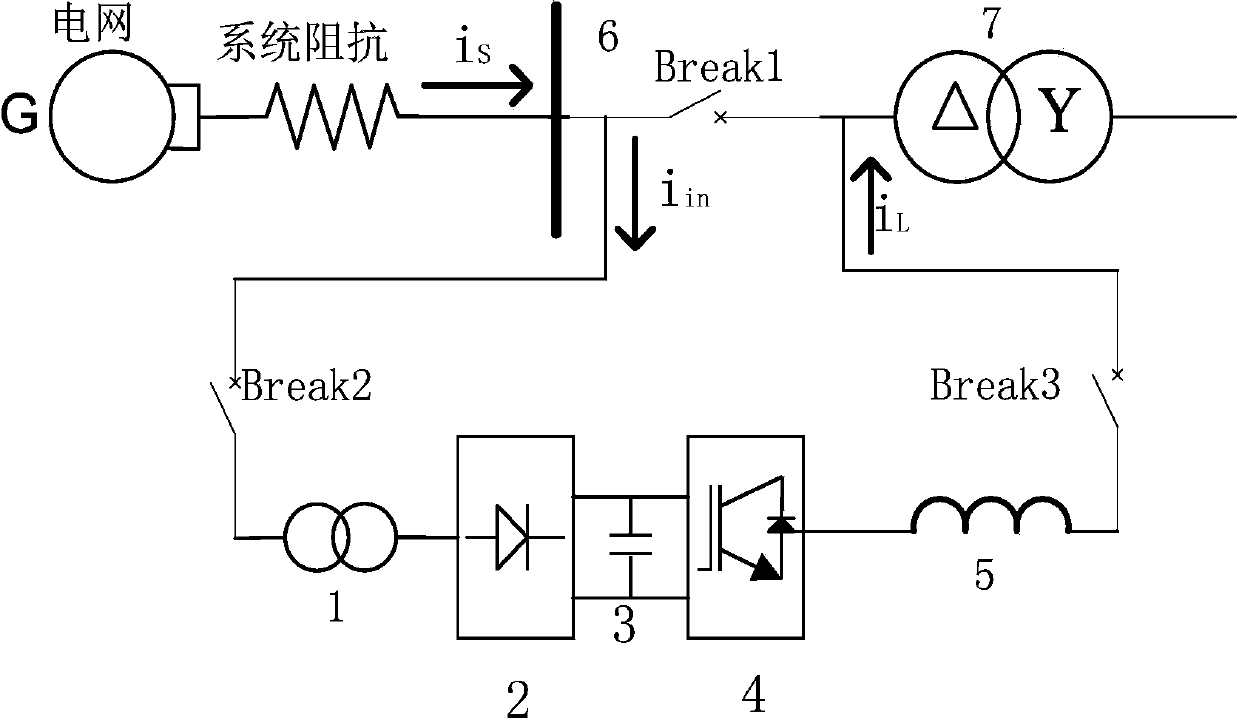

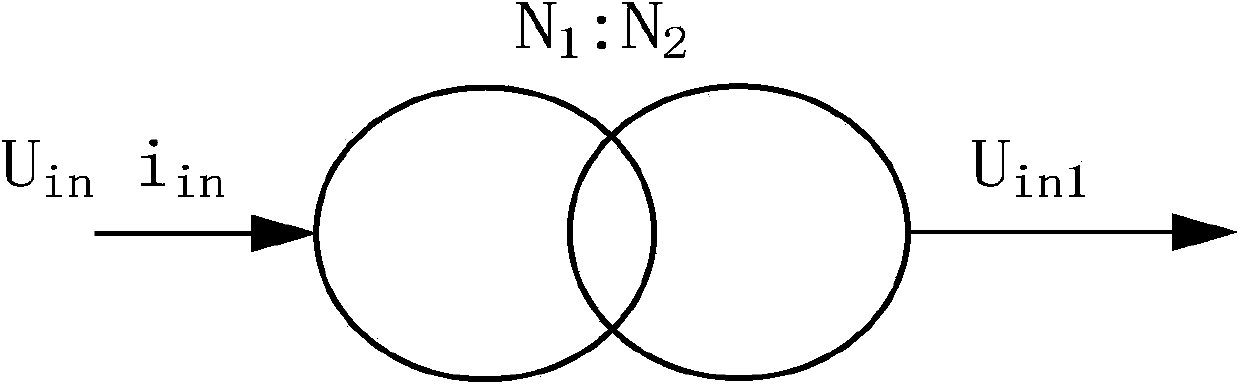

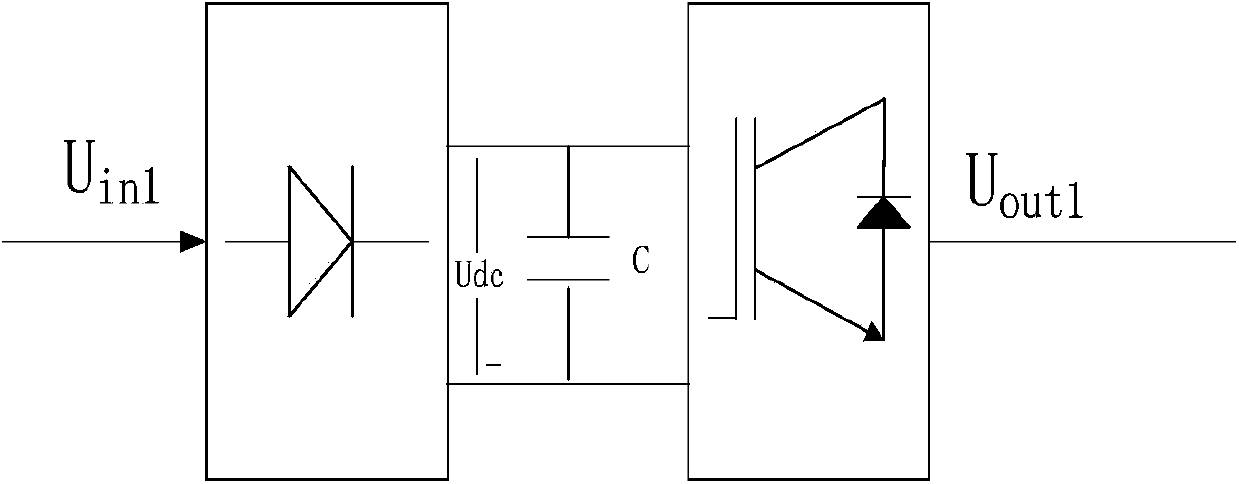

Ship transformer excitation surge current restraining device

ActiveCN103956722ASimple structureLow implementation costEmergency protective arrangements for limiting excess voltage/currentCapacitanceInductor

The invention relates to a ship transformer excitation surge current restraining device which is connected between a power supply bus and a ship transformer. The restraining device comprises a miniature transformer, a rectifier, a voltage stabilization capacitor, an inverter and an output inductor, wherein the miniature transformer, the rectifier, the voltage stabilization capacitor, the inverter and the output inductor are sequentially connected. The primary side of the miniature transformer is connected with the power supply bus and the output end of the output inductor is connected with the ship transformer. The miniature transformer is used for increasing the voltage at the secondary side and achieving the function of isolation protection. Alternating current is changed into direct current through the rectifier. A charging capacitor is used for supporting the voltage at the direct current side and flat waves at the same time. The output inductor is used for filtering out high-frequency glitches. Compared with the prior art, the ship transformer excitation surge current restraining device has the advantages that the structure is simple, excitation surge current can be effectively restrained, the responding speed is high, and the restraining effect is good.

Owner:SHANGHAI JIAO TONG UNIV

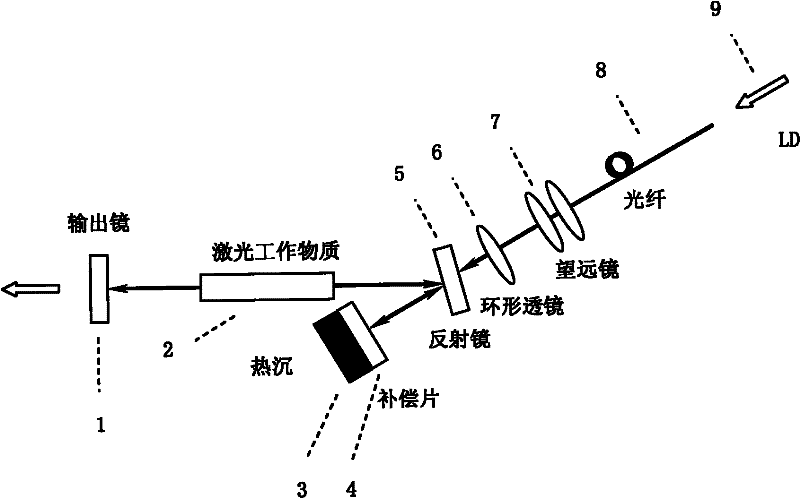

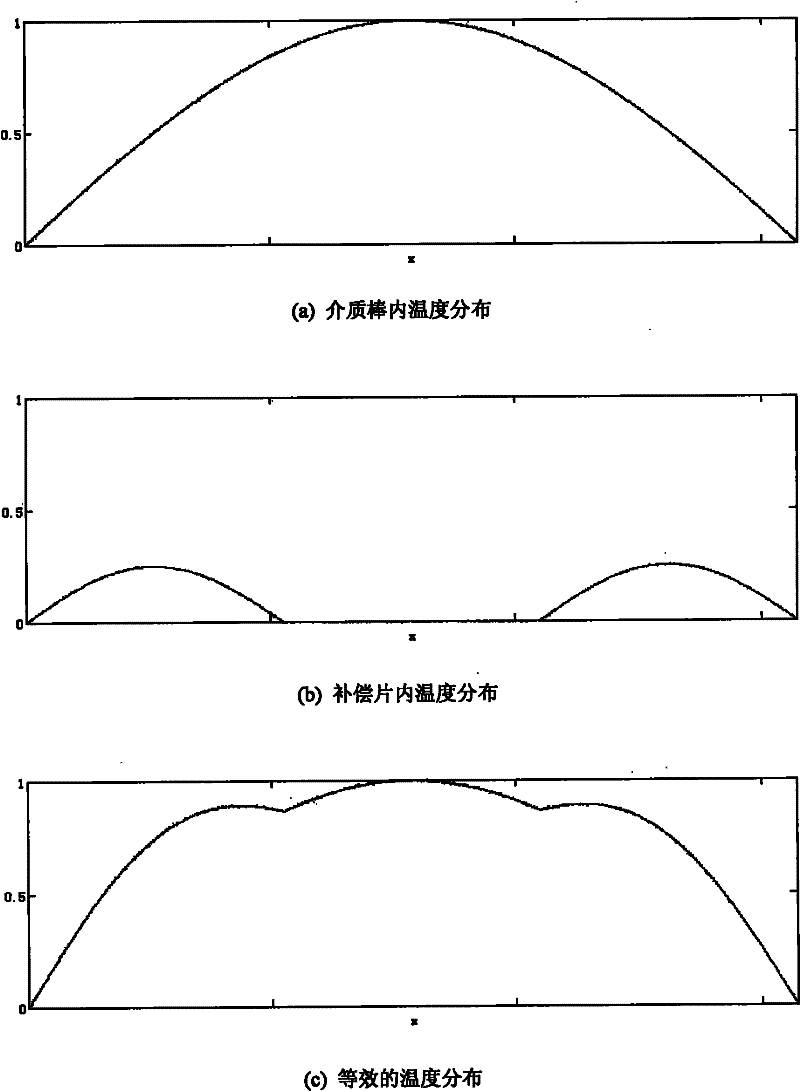

Laser Thermal Effect Compensation System

InactiveCN102280800ARealize dynamic compensationEasy to implementLaser cooling arrangementsThermal effectTelescope

The invention provides a novel method for compensating the thermal effect of a solid-state laser. A thermal effect compensation system is added in the laser oscillation cavity, which consists of a heat sink (3), a compensation sheet (4), an annular transmittance lens (6), a telescope (7), an optical fiber (8), and an LD (9) . By adjusting the cooling temperature of the heat sink, the input power of the LD, or the displacement or focal length of the annular transmittance lens, the bulk temperature distribution of the compensation sheet can be finely changed, and the thermal lens effect of the laser working substance (2) can be compensated. By designing different body and surface temperature distributions of the compensation sheet, the invention can be used to compensate thermal lens effects of various orders of different lasers such as rods, slabs, side pumps, and end pumps. It is characterized in that an optical medium that can dynamically adjust its own temperature distribution and a corresponding temperature control system are inserted into the laser resonator cavity to realize fine dynamic compensation for the thermal effect of the laser.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Double-pulse combustion device with common-chamber time-sharing ignition output

ActiveCN110792526AImprove reliabilityRealize dynamic compensationRocket engine plantsControl theoryMechanical engineering

The invention discloses a double-pulse combustion device with a common-chamber time-sharing ignition output. The first-stage charging and the second-stage charging are installed in a shell component in series, a first-stage ignition component is installed on the shell component and is connected with the first-stage charging in a matching mode, a second-stage ignition component is installed on theshell component and is connected with the second-stage charging in a matching mode, the first-stage charging and the second-stage charging are separated into two independent combustion units by adopting a partition layer component, a one-way valve component is arranged between the first-stage charging and an exhaust port of the shell component, and the sealing end of the shell component adopts a snap ring component to fix end cover components to the shell body component, and the sealing is achieved. According to the technical scheme, the space utilization rate is improved, so that the charge quantity is increased, dynamic compensation of the gas quantity of a gas storage device is realized, insufficient inflation or overpressure is effectively avoided, the reliability of ignition gas production is improved, and the double-pulse combustion device has the advantages that the structure is compact and reasonable, the installation is simple, and the extended application is flexible.

Owner:湖北三江航天红林探控有限公司

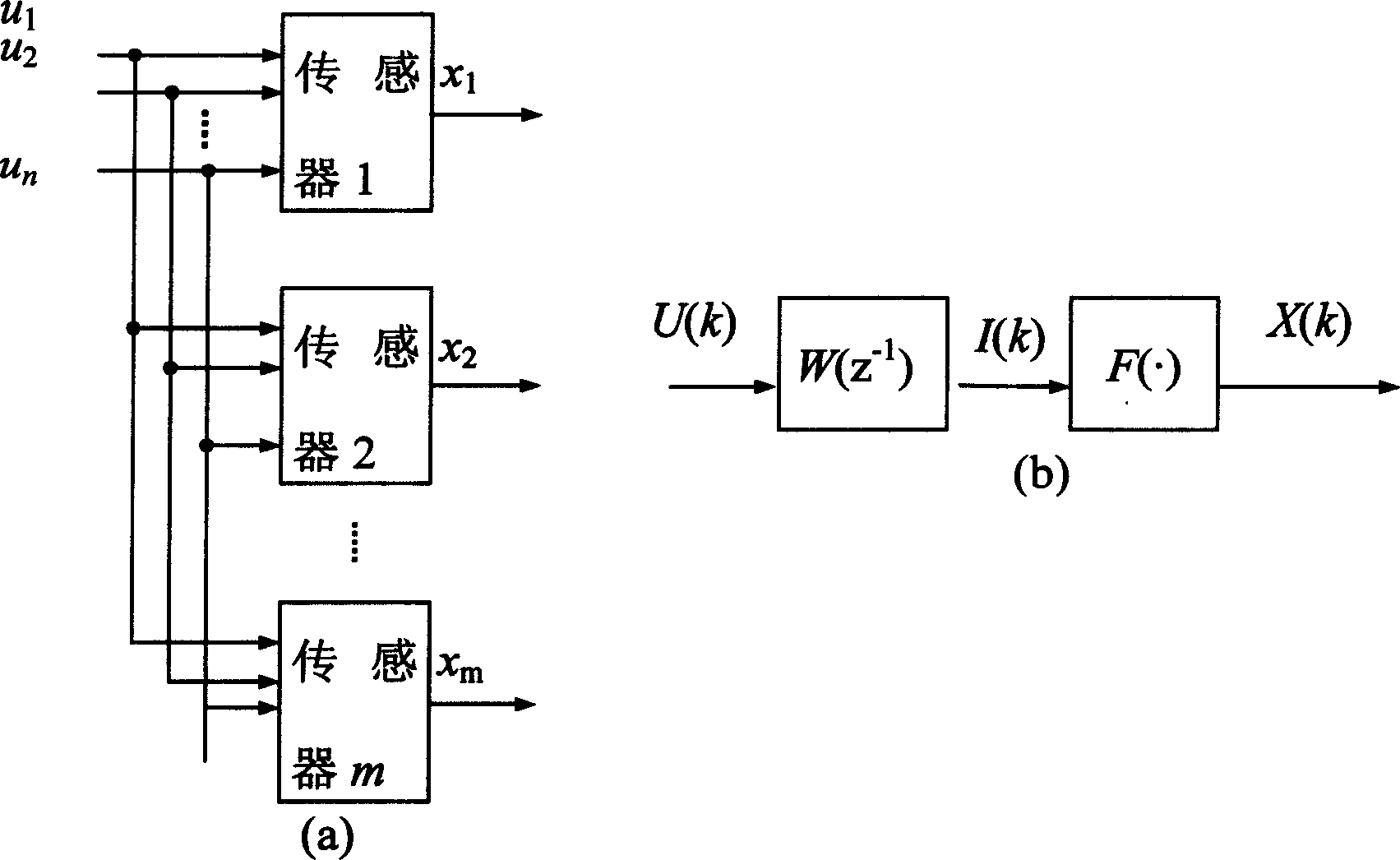

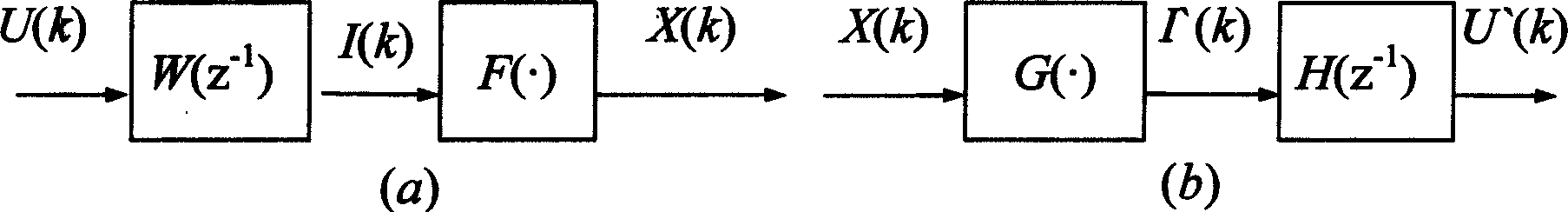

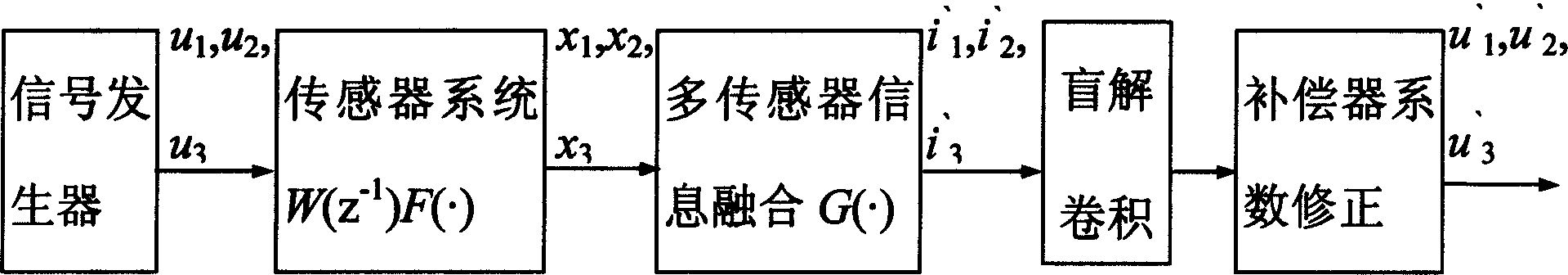

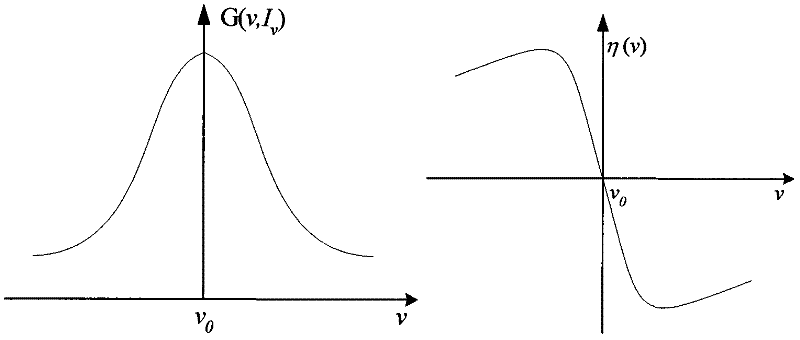

Dynamic compensation method of multi-input detection system under conditions of cross sensitiveness

InactiveCN1563899ARealize dynamic compensationHigh bandwidthMitigation of undesired influencesMulti inputMultiple sensor

The invention is applicable to crossed sensitive sensors working at situation, where multiple sensing parameters are time varying dynamic signals so as to realize purpose of expanding frequency band and reducing distortion factor of dynamic measurements. Cascading sensors to be compensated, eliminating static crossed sensitive step for synthesize synthesizing data in multiple inputs and outputs, as well as multidimensional dynamic compensator constitute a multiple sensors system with multiple inputs compensable through method of multidimensional dynamic compensation. The system is a convolution system. Carrying out experiment of multidimensional dynamic calibration for the convolution system, and carrying out deconvolution blindly can obtain initial multidimensional dynamic compensators. Method of lowpass gain modification modifies issues of difficulties for sorting signals and unable to determine amplitudes, and obtains modified multidimensional dynamic compensators.

Owner:XI AN JIAOTONG UNIV

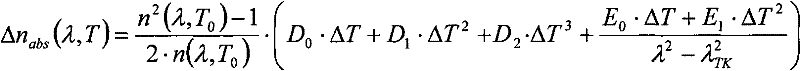

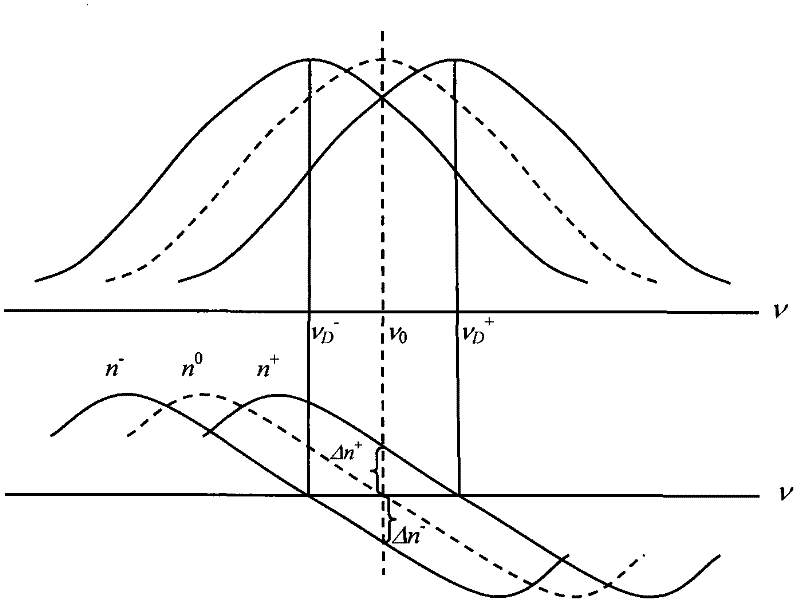

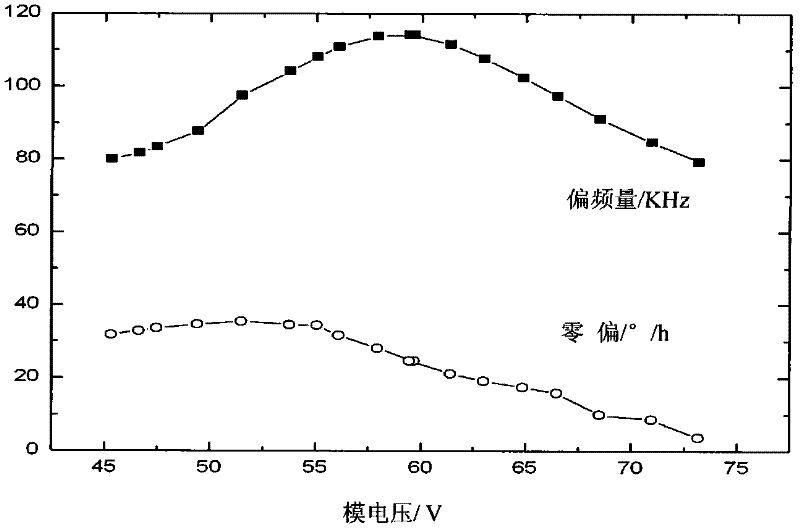

Dispersion control method for zeeman laser gyroscope

ActiveCN102506846AEliminate zero offset transition processFaster startup and improved performanceSagnac effect gyrometersOptical elementsPerformance improvementControl parameters

The invention belongs to the field of optics and relates to a dispersion control method for a zeeman laser gyroscope. The method comprises the following steps of: taking an offset frequency volume and a temperature as a control parameter and a control switch; establishing a dispersion control model, namely, delta V=F (fb, T); controlling the offset volume delta V of a work voltage of a component by cavity length; and setting a working point offset of a zeeman laser gyroscope frequency-stabilizing system, thereby realizing the dispersion control. A dynamic compensating control device is established, and a dispersion error caused by the violent change of the temperature of a resonant cavity is compensated by the working point of the cavity length under real-time control, thereby greatly weakening and even eliminating a zero offset transition process of a full-solid laser gyroscope, realizing the quick starting and the performance improvement of the full-solid laser gyroscope, and further widening the application field of the gyroscope.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

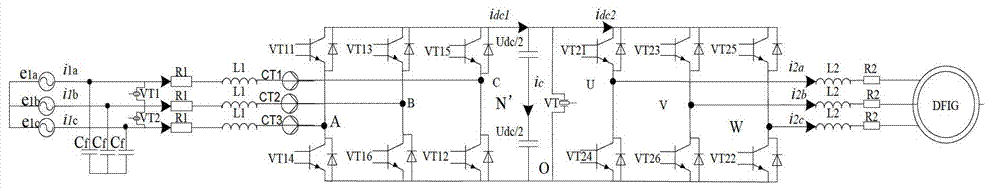

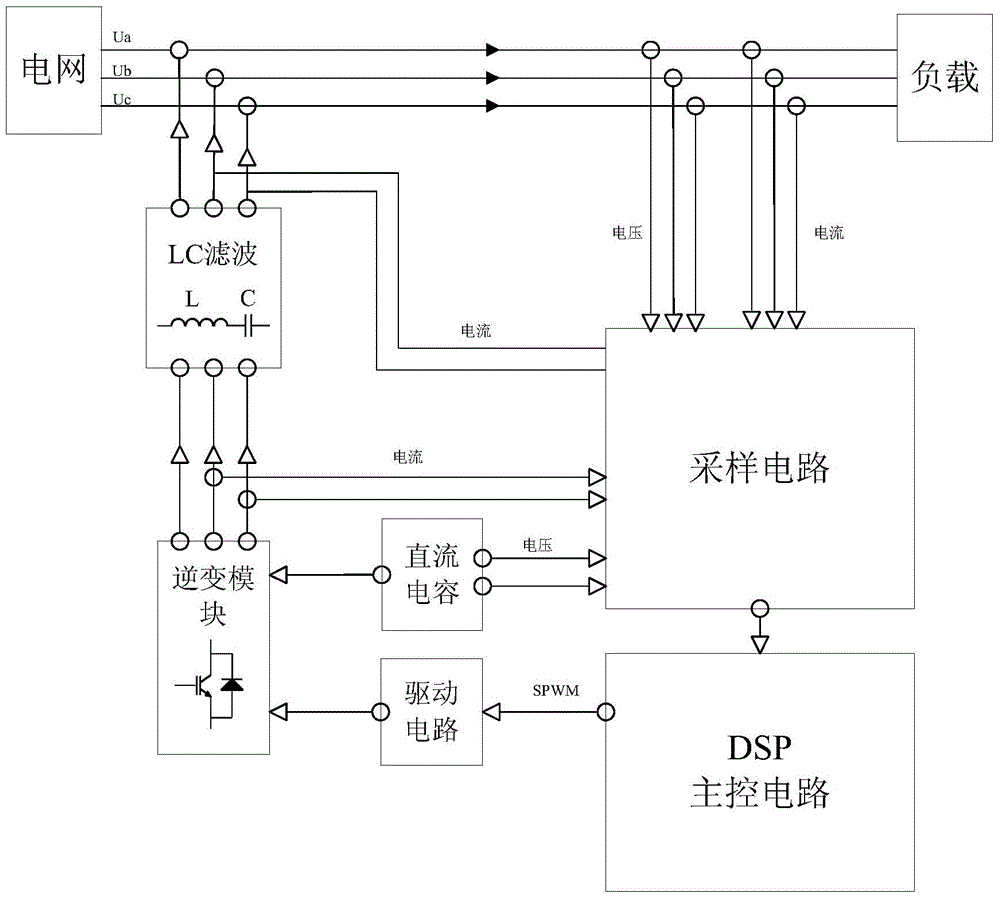

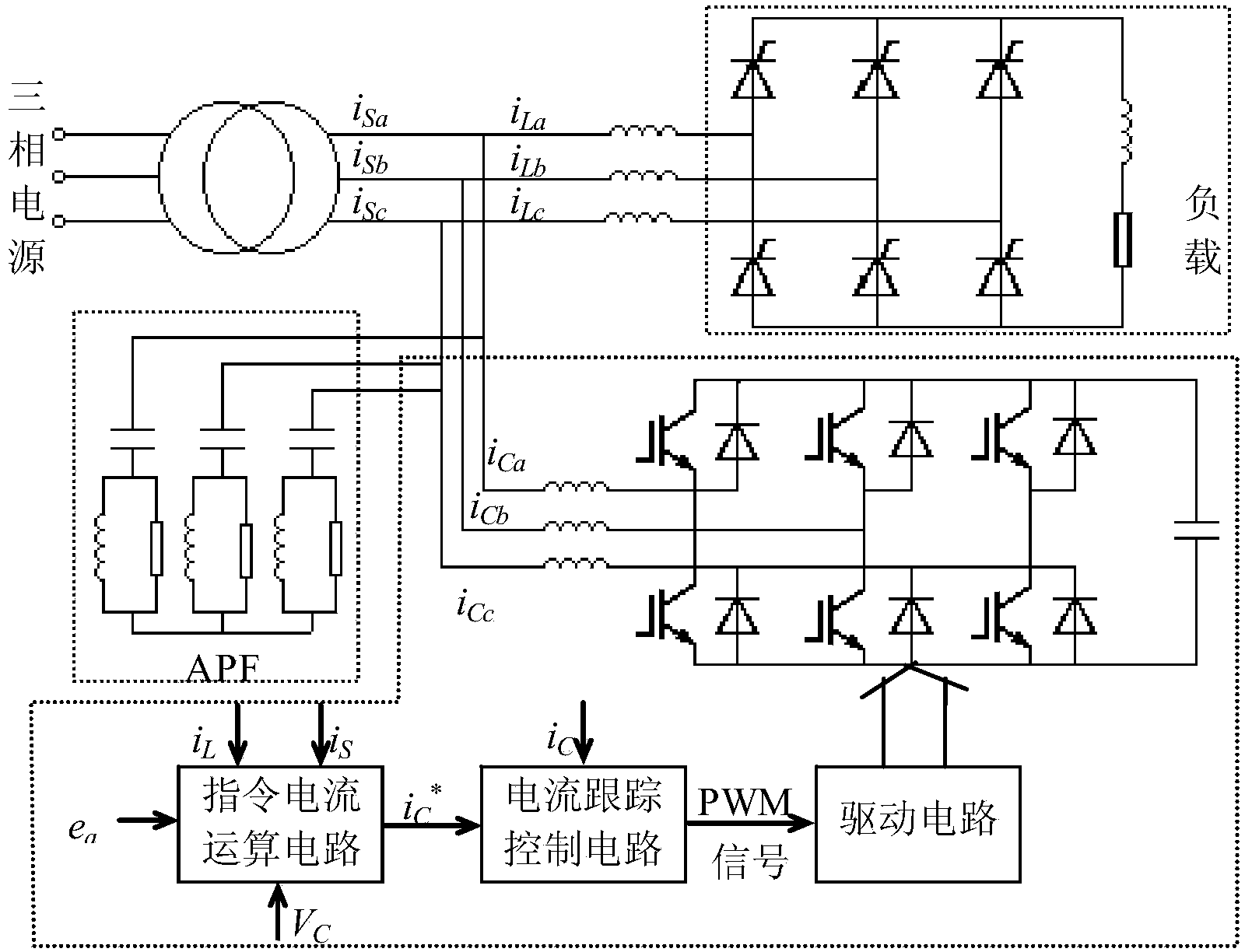

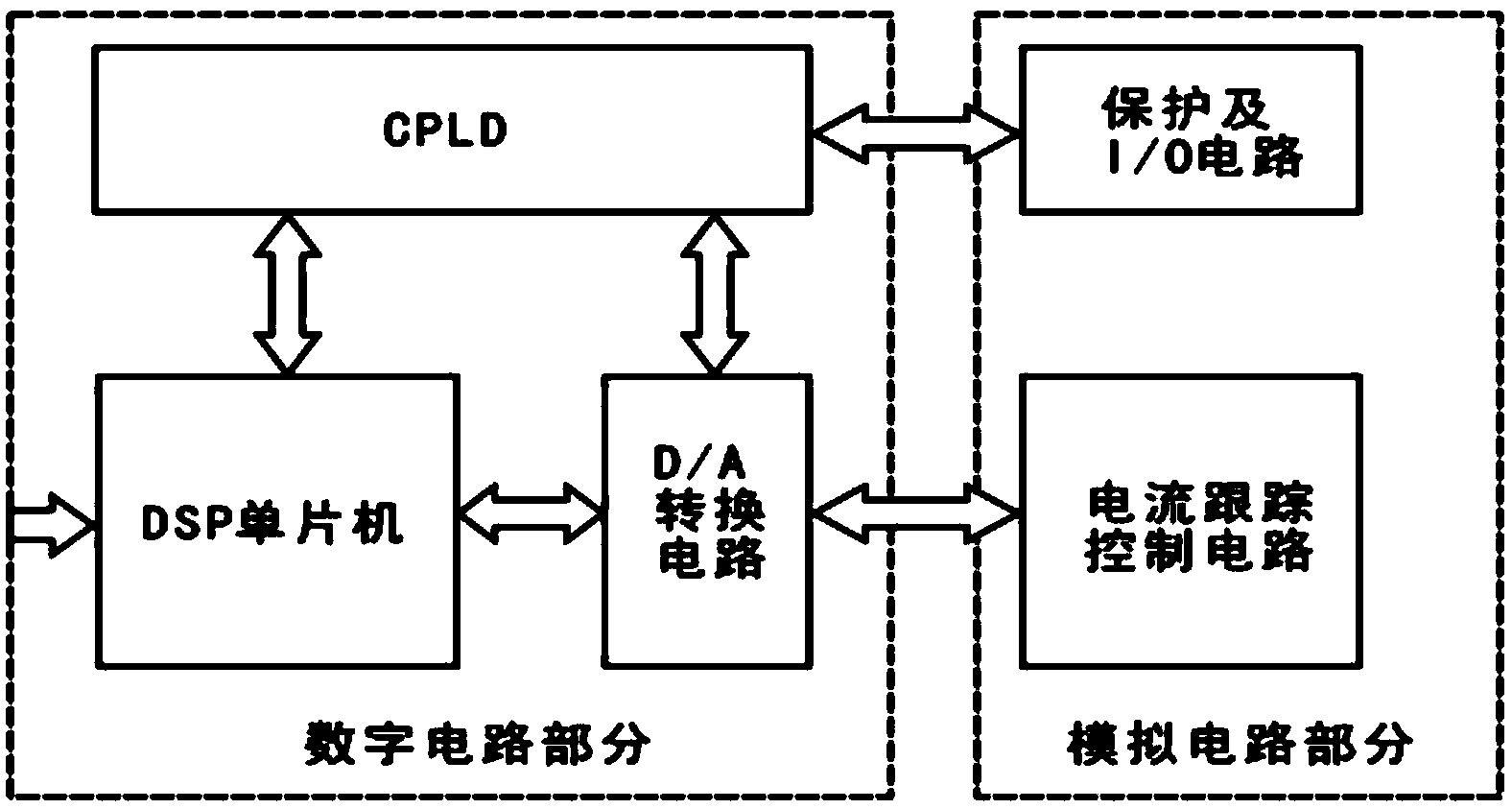

Active harmonic management device

InactiveCN104135004ALarge capacityRealize dynamic compensationReactive power adjustment/elimination/compensationReactive power compensationDriver circuitHarmonic

The invention discloses an active harmonic management device. The device comprises an instruction current operational circuit and a compensating current generation circuit. The instruction current operational circuit is used for detecting harmonic wave and reactive power current components in compensating load currents, and the compensating current generation circuit is used for generating actual compensating currents according to an instruction signal of the compensating currents, wherein the instruction signal is obtained according to the instruction current operational circuit. The compensating current generation circuit comprises a main circuit, a driving circuit and a current tracking and controlling circuit. The active harmonic management device has the advantages that dynamic compensation is achieved, harmonic waves changeable in frequency and size and changeable reactive power can be compensated, and response to changes of a compensated object is rapid; the harmonic waves and the reactive power can be compensated at the same time, and the intensity of the compensated reactive power can be continuously adjusted; influences caused by power grid impedance are small, and harmonic vibration between the active harmonic management device and the power grid impedance is not prone to occurring; changes of power grid frequencies can be tracked, so that the compensating performance is not affected by the changes of the power grid frequencies.

Owner:SICHUAN KERUISI ENERGY TECH

Visual servo control system based on multi-core processor

InactiveCN107272578AReduce gapFast data processingProgramme controlComputer controlAutomatic controlControl system

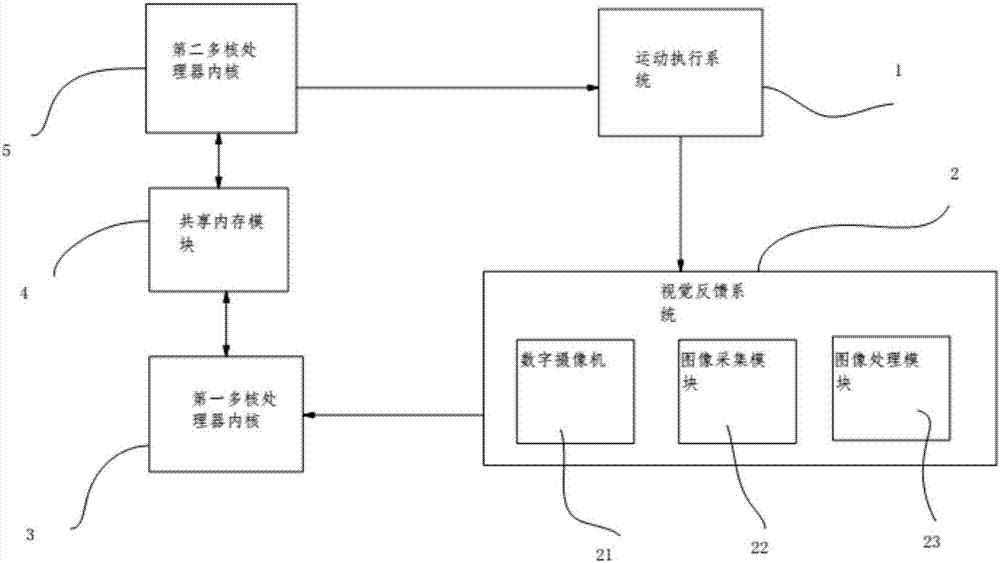

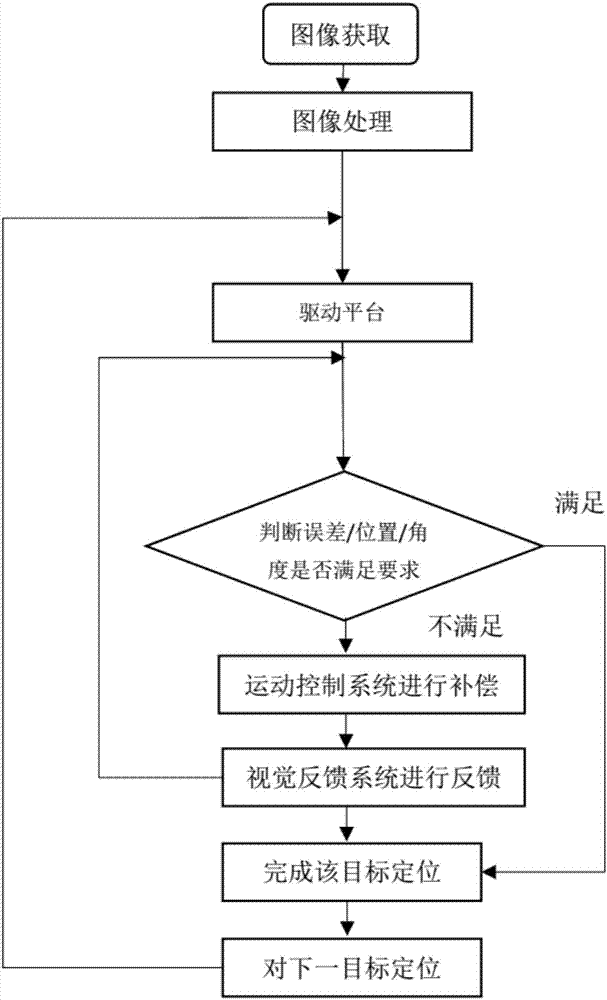

The invention belongs to the technical field related to automatic control and discloses a visual servo control system based on a multi-core processor. The visual servo control system includes a motion executing system and a visual feedback system connected to the motion executing system. The visual servo control system further includes a multi-core processor which is connected to the motion executing system and the visual feedback system. The multi-core processor includes a first multi-core processor core connected to the visual feedback system and a second multi-core processor core connected to the motion executing system, wherein the first multi-core processor is connected to the second multi-core processor core through a shared memory module. The first multi-core processor core and the second multi-core processor core of the visual servo control system process the data of the visual feedback system and the data of the motion executing system respectively to reduce a difference between a visual servo cycle and a motion servo cycle, thereby improving the real-time performance of the system.

Owner:HUAZHONG UNIV OF SCI & TECH

Field programmable logic array and serial data receiving and converting method

ActiveCN104750422ARealize dynamic compensationRealize regulationInput/output processes for data processingEngineeringClock phase

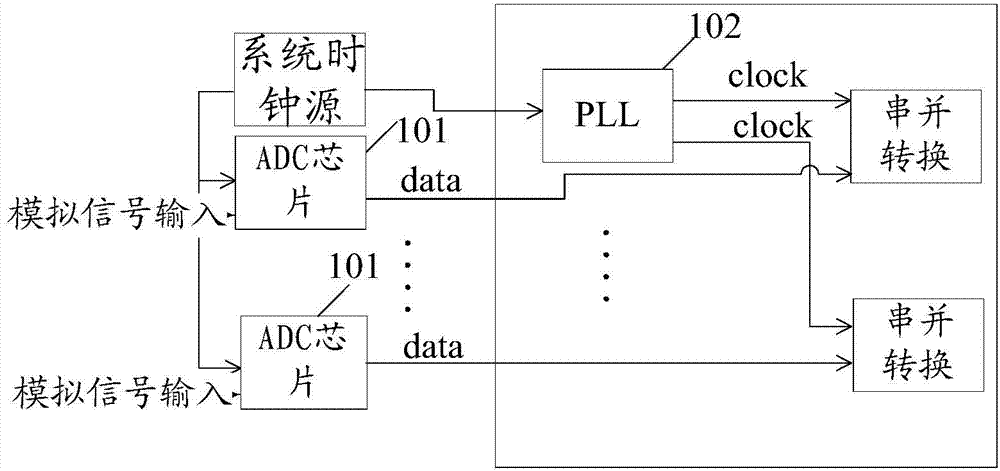

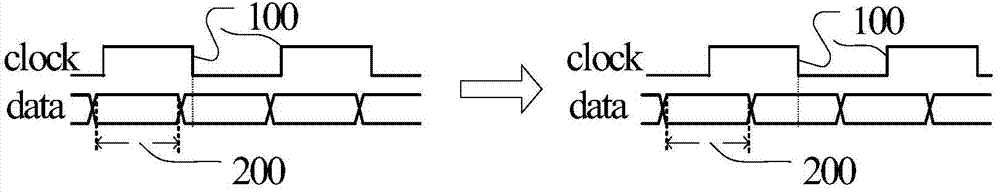

The invention discloses a field programmable logic array. Through a control unit, the output of N analog-digital converter chips and a phase lock loop are independently controlled, the position regulation of N output clock phases output by the phase lock loop and the word regulation of parallel data output by N deserialized units are independently realized, and the dynamic compensation of time migration between a latch clock and a data channel is realized; then, the N analog-digital converter chips are controlled to output normal signals; and N deserialized units generate and output parallel data under a normal work state according to the normal signals output by the N analog-digital converter chips and the regulated output clock phase output by the phase lock loop. The field programmable logic array only needs one phase lock loop to realize regulation and parallel output, so that the time migration from the latch clock to the data channel can be dynamically compensated while the resources of the phase lock loop of the field programmable logic array are fully utilized.

Owner:SONOSCAPE MEDICAL CORP

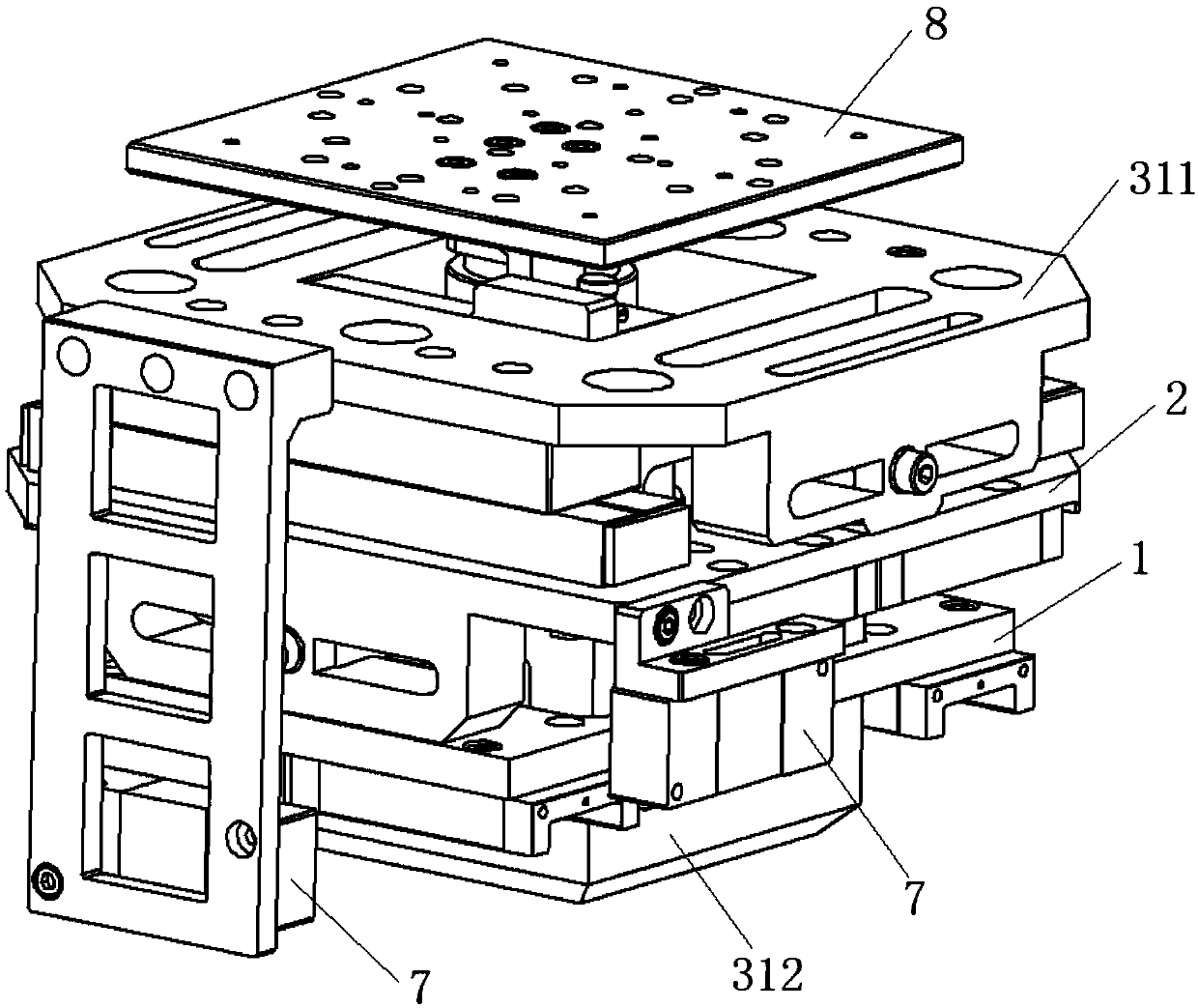

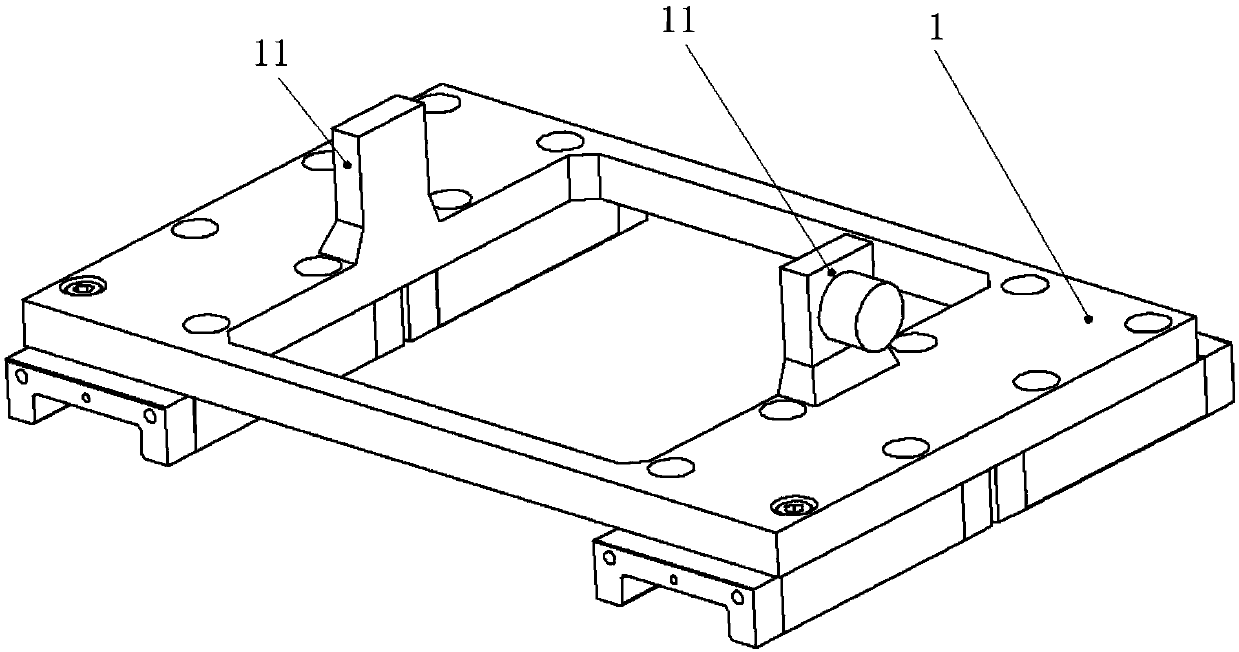

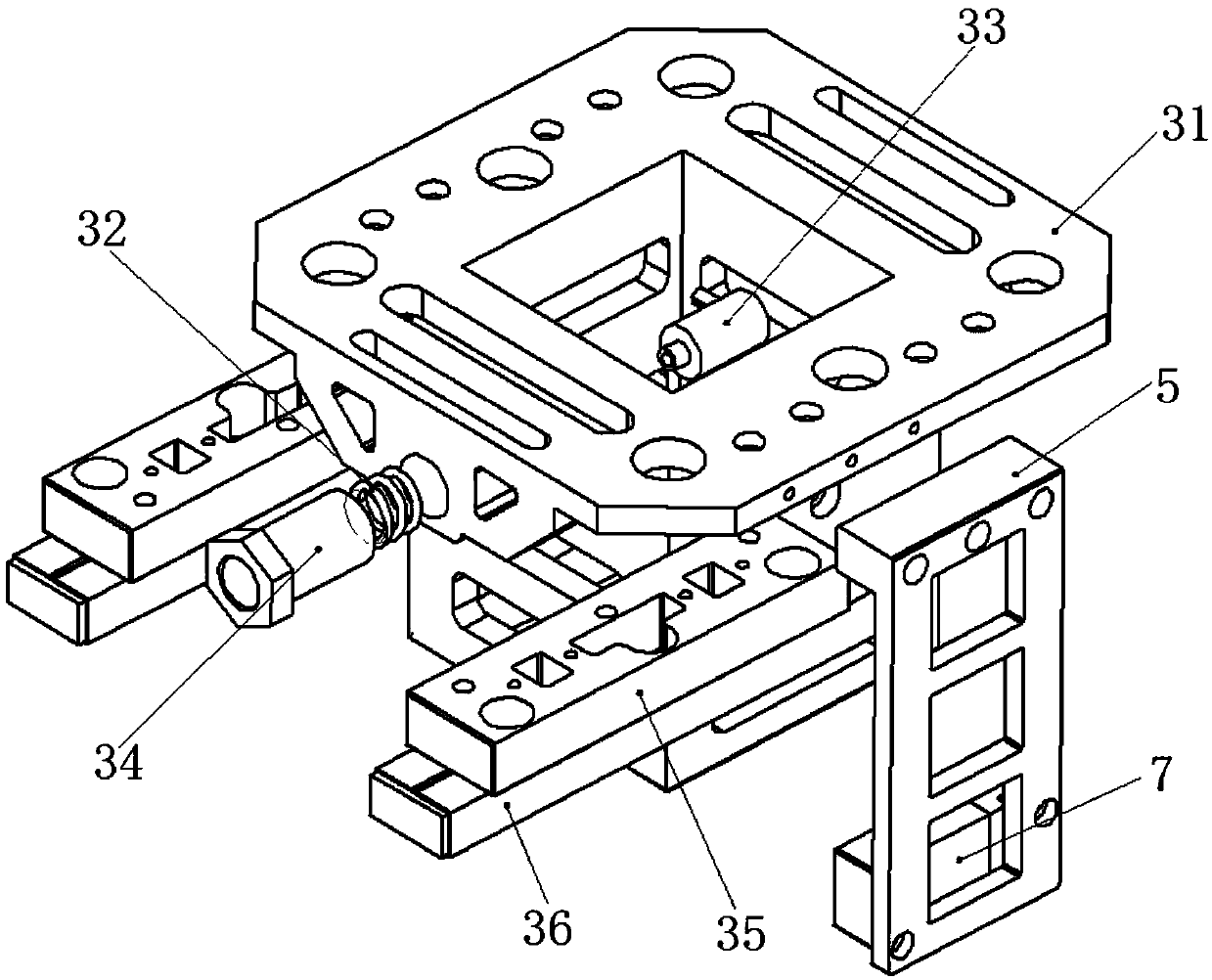

Mosaic laminated type XYZ three-dimensional dynamic microdrive device

PendingCN109686690ARealize dynamic compensationRealize functionSemiconductor/solid-state device manufacturingConveyor partsPersonal computerEngineering

The invention provides a mosaic laminated type XYZ three-dimensional dynamic microdrive device. The mosaic laminated type XYZ three-dimensional dynamic microdrive device comprises a bottom plate, a Y-directional precision compensation unit arranged on the bottom plate, and an X-directional precision compensation unit penetrating through the bottom plate and the Y-directional precision compensationunit from top to bottom, and further comprises a Z-directional precision compensation unit, wherein the Z-directional precision compensation unit is fixedly arranged inside the X-directional precision compensation unit, fixedly arranged on the lower surface of a terminal platform and used for compensating micro displacement of the terminal platform in the Z-axis direction; and the mosaic laminated type XYZ three-dimensional dynamic microdrive device further comprises a reading unit used for reading displacement in the X-axis, Y-axis and Z-axis directions, and an industrial personal computer used for correspondingly controlling the X-directional precision compensation unit, the Y-directional precision compensation unit and the Z-directional precision compensation unit. According to the mosaic laminated type XYZ three-dimensional dynamic microdrive device, a mosaic laminated type structure is adopted, the structure is compact, a framework is simplified, the mounting space is effectivelysaved, motion precision is improved, the functions of three-dimensional collaborative dynamic compensation and dynamic damping are realized, and the precision movement of the terminal platform is ensured.

Owner:GUANGDONG UNIV OF TECH

High-speed shearing emulsification device and flotation complete equipment

ActiveCN111570097ASimple structureGood emulsifying effectRotating receptacle mixersFlow mixersElectric machineWater flow

The invention discloses a high-speed shearing emulsification device and flotation complete equipment. The high-speed shearing emulsification device comprises an emulsifying tank, a medicament spray head, a rotary fluted disc and a fixed fluted disc; the medicament spray head is mounted at the top end of the emulsifying tank and is connected with a water flow injection pipe; the rotary fluted discand the fixed fluted disc are oppositely arranged; a sawtooth-shaped shearing flow channel is formed between the rotary fluted disc and the fixed fluted disc; a motor is connected with the bottom endof the rotary fluted disc through a transmission shaft; the rotary fluted disc is driven by the motor to rotate at a high speed; a mixed solution of a collecting agent and water is sheared at a high speed in the sawtooth-shaped shearing flow channel to be fully mixed and emulsified. The flotation complete equipment is simple in structure and good in emulsification effect; the flotation complete equipment integrates an injection atomization device, the high-speed shearing emulsification device and a double-connection-wheel jet agitation mechanism, and therefore, the size of the equipment is greatly reduced, area occupied by the equipment is greatly reduced, the energy consumption of ore pulp pumping is reduced, and meanwhile, mineral separation efficiency is improved.

Owner:ANHUI UNIV OF SCI & TECH

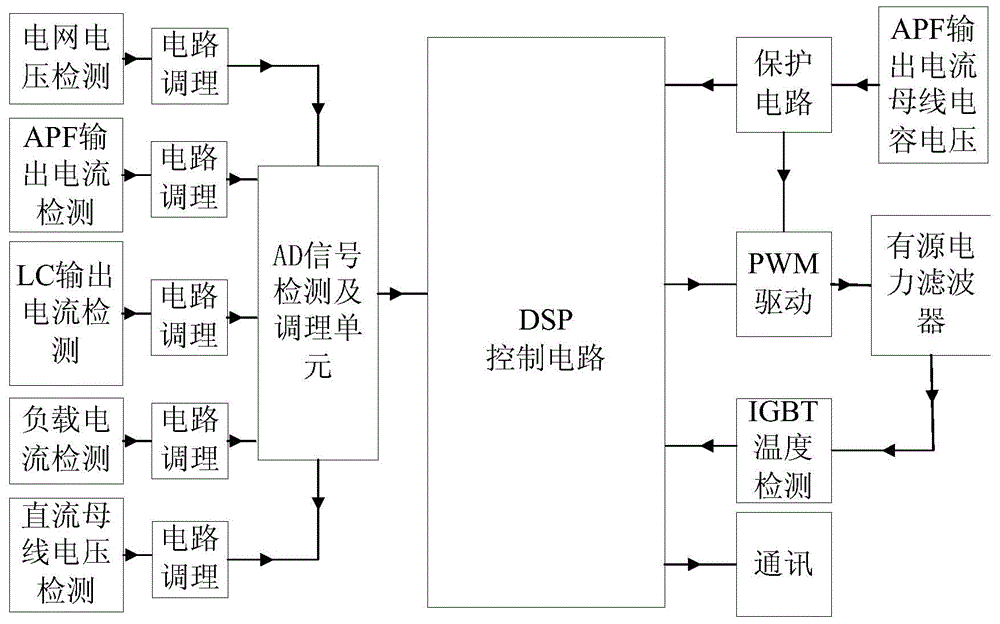

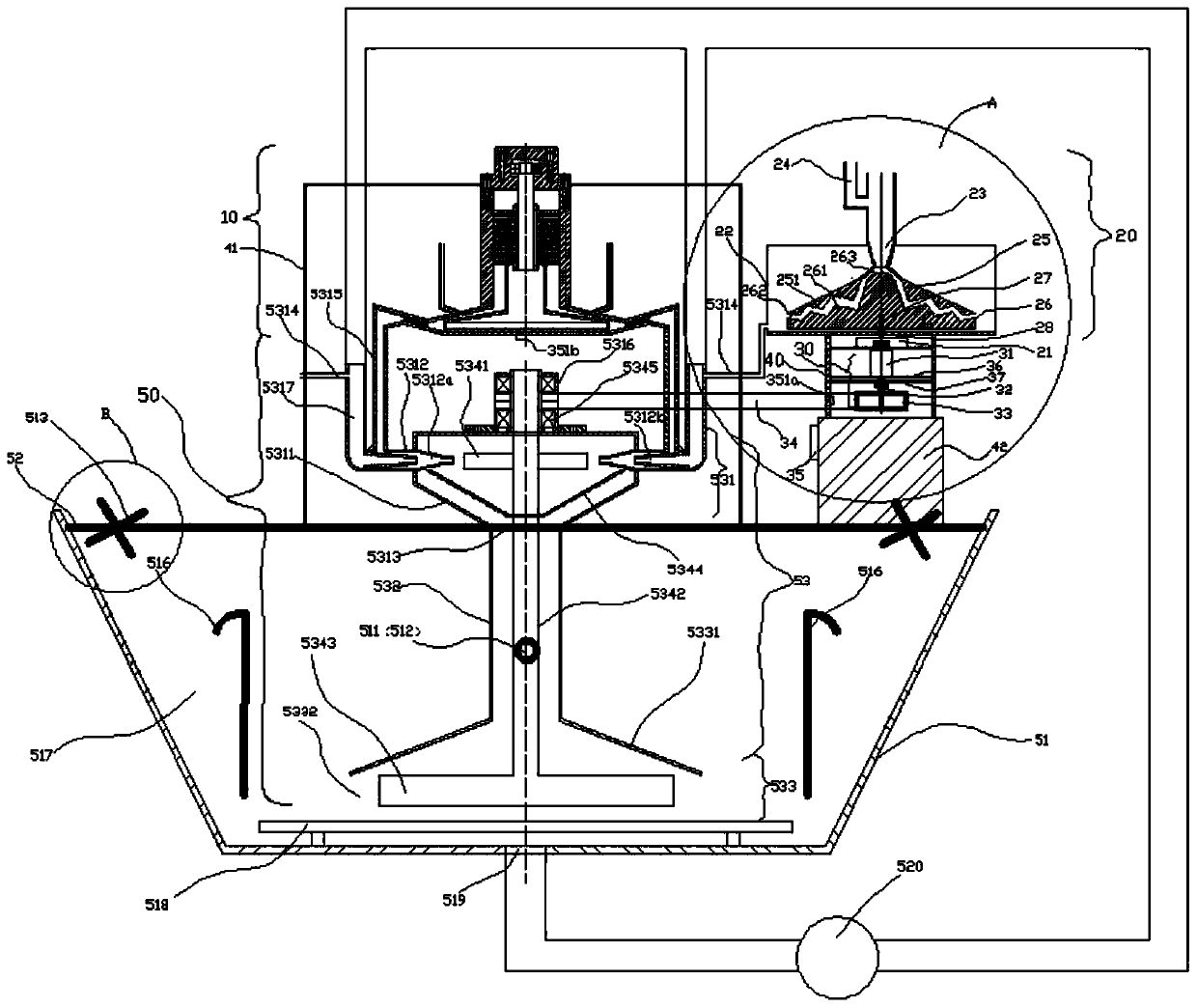

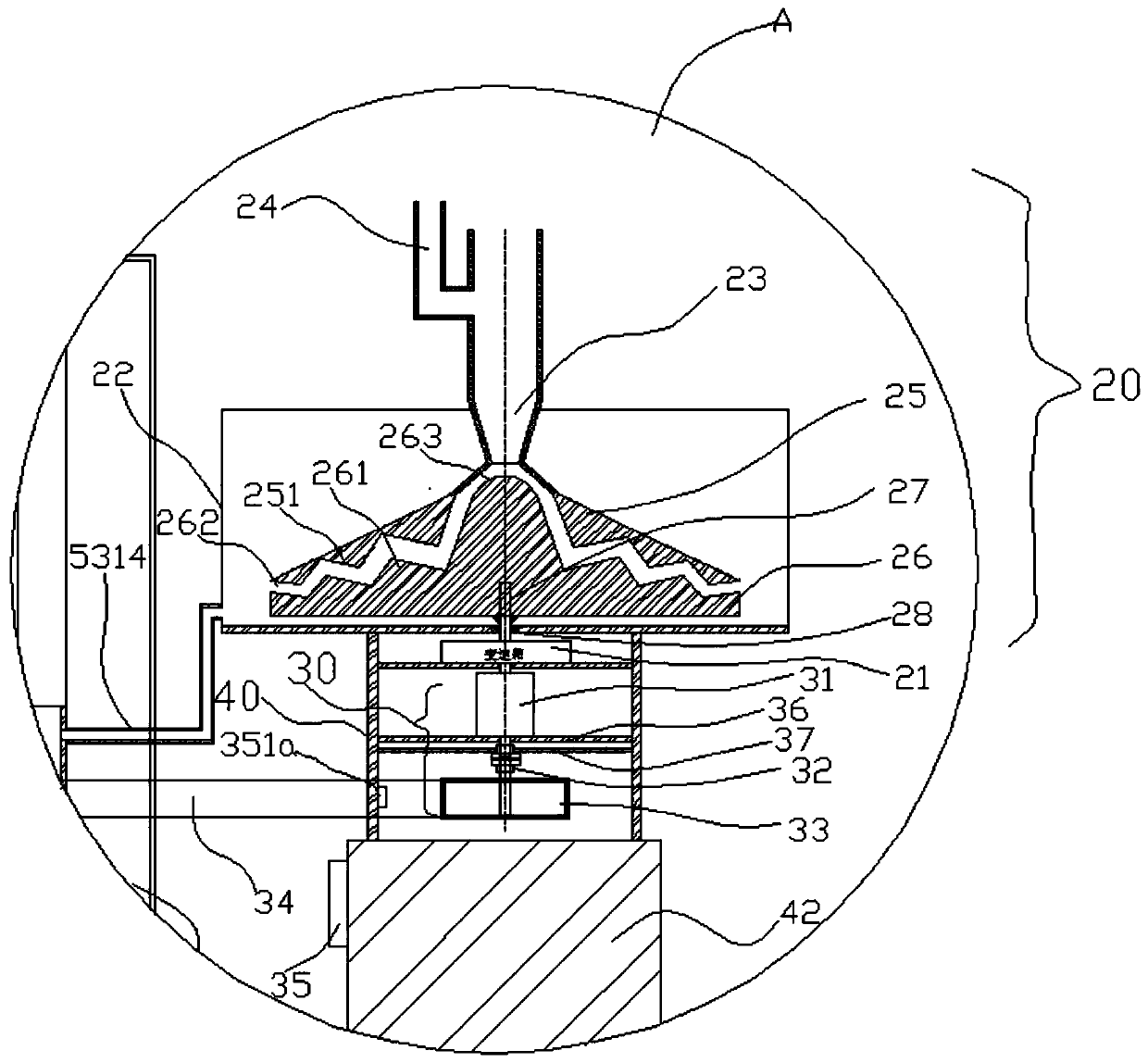

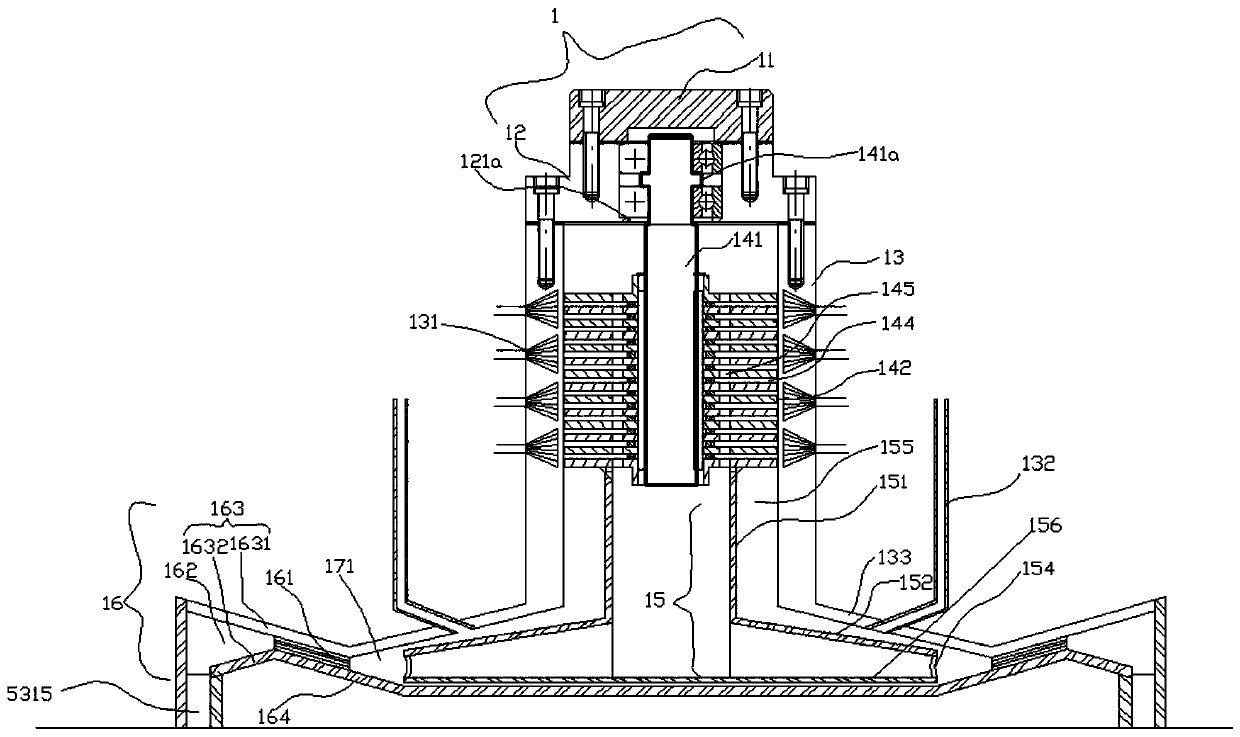

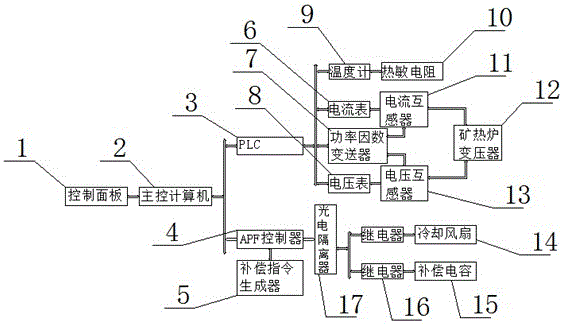

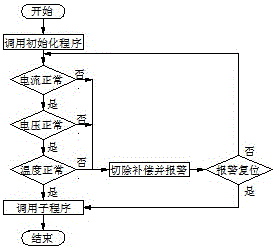

Control system for low-voltage compensation device of ferroalloy submerged arc furnace

ActiveCN106300382AFirmly connectedEasy to useActive power filteringReactive power adjustment/elimination/compensationCapacitanceDigital signal processing

The invention discloses a control system for a low-voltage compensation device of a ferroalloy submerged arc furnace. The control system comprises the components of a control panel, a master control computer, a PLC, an APF controller, a compensation instruction generator, an ammeter, a power factor transmitter, a voltmeter, a thermometer, a thermistor, a current transformer, a submerged arc furnace transformer, a voltage transformer, a cooling fan, compensation capacitors, a relay and an optoelectronic isolator. The control system for the low-voltage compensation device is advantageous in that stable connection and simple operation in use are realized; the control system can detect various parameter data in the submerged arc furnace in real time; real-time compensation is performed through controlling by the control system; dynamic compensation is realized; the control system has two compensation capacitors; relatively quick response to a compensation object is realized; furthermore continuous compensation power adjustment can be realized; the APF controller has relatively high real-time controlling performance and can satisfy requirements of digital signal processing and system controlling. The control system further has advantages of improving compensation control precision, realizing high stability in operation, and obtaining high suitability for popularization.

Owner:四川晨龙航天电器设备有限公司

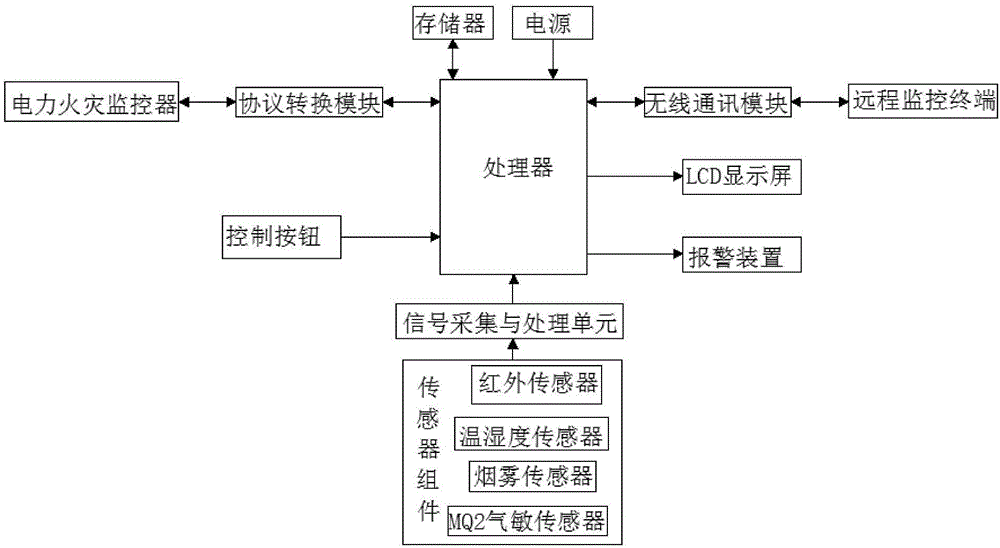

Intelligent security and protection early-warning system

InactiveCN106128002AIncrease flexibilityQuick responseFire alarm electric actuationFire alarm smoke/gas actuationEarly warning systemResonance

The invention discloses an intelligent security and protection early-warning system comprising a power supply, a processor, a memory device and an alarm device. The power supply is connected with the input terminal of the processor electrically; a wireless communication module and a remote monitoring terminal are in signal connection; the processor is connected with a sensor assembly by a signal acquisition and processing unit; and the output terminal of the processor is connected with an electric fire monitoring device by a protocol conversion module. Compared with the traditional security and protection early-warning system, the provided system has the following beneficial effects: the electric fire monitoring device employs an improved HHT technology to detect harmonic waves; an APF filter having a fast response speed is connected in parallel to suppress series-parallel connection resonance, thereby realizing dynamic compensation. An active filter device has advantages of a PPF and an APF, so that multiple harmonic waves can be suppressed effectively and reactive compensation can be provided. The system is suitable for high-voltage distribution network.

Owner:CHENGDU ZHIQI TECH

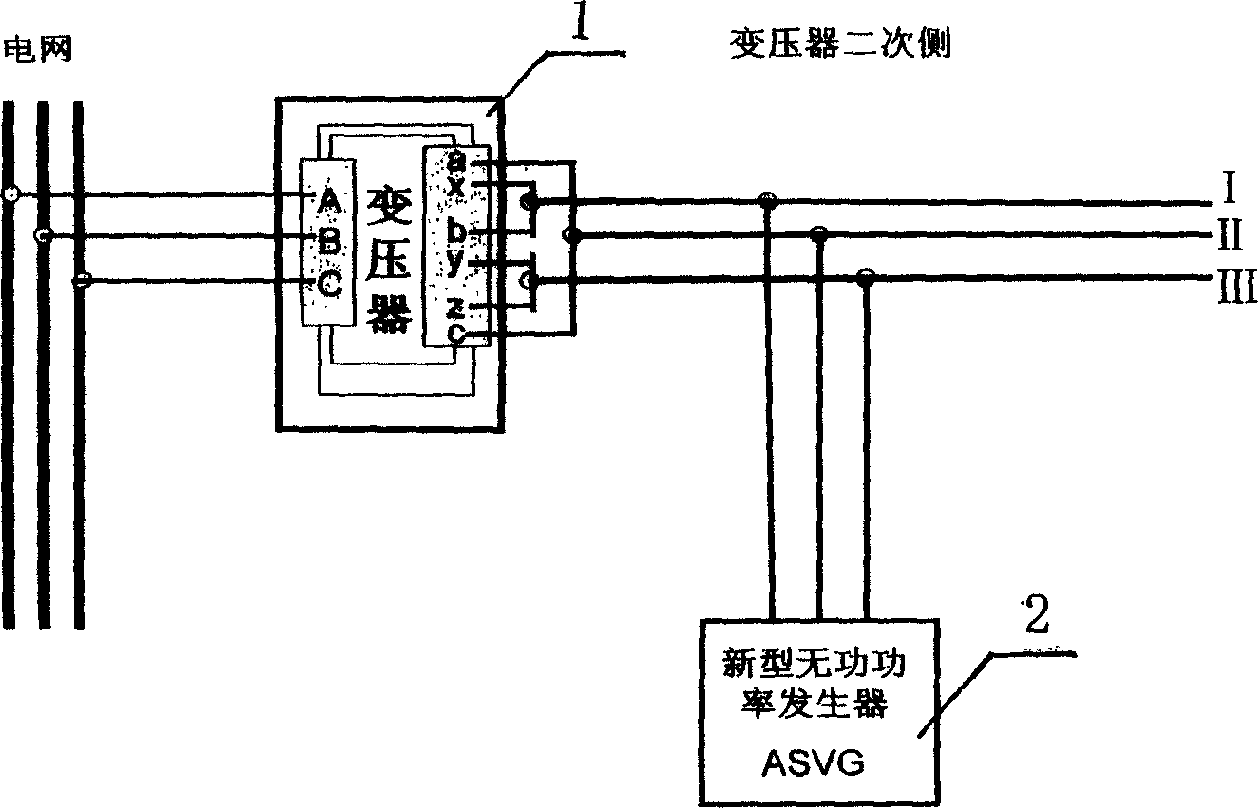

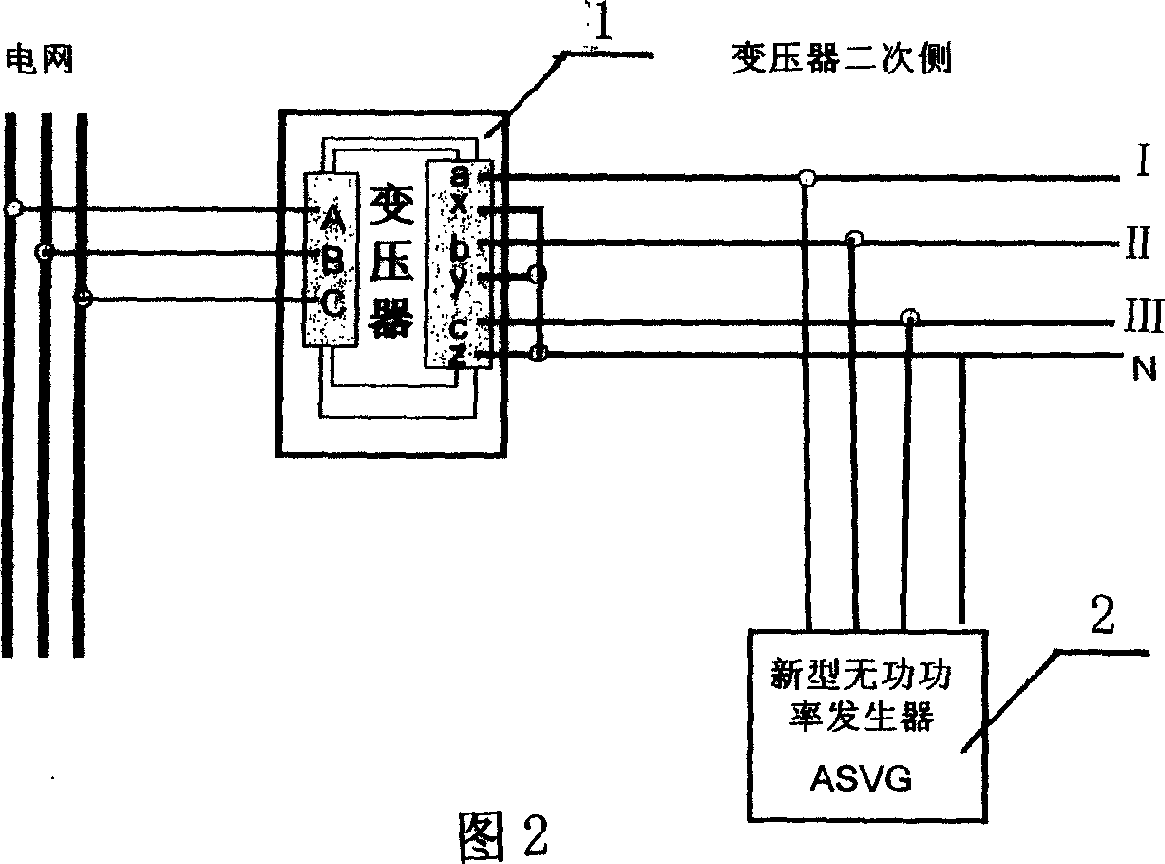

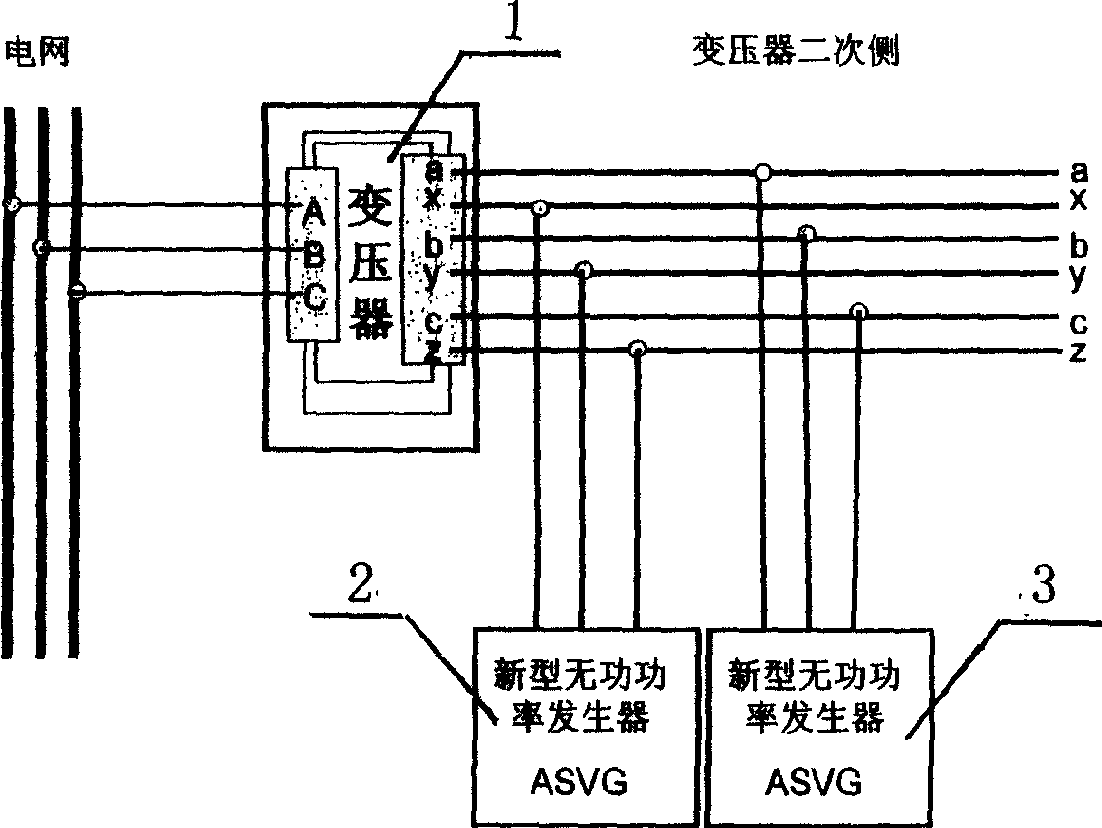

Method of secondary side connecting reactive power generator of smelting transformer

InactiveCN1564417AQuick responseWith adaptive functionReactive power adjustment/elimination/compensationReactive power compensationHarmonicEngineering

The method includes following approaches: (1) a new type reactive power generator is connected in parallel to three phases of major loop at secondary side in three phase three wire system or three phase four wire system; (2) or a new type reactive power generator is connected in parallel to head part of secondary winding of three phases of major loop at secondary side in three phase three wire system as well as a new type reactive power generator is connected in parallel to tail part of secondary winding of three phases; (3) or in building block mode, multiple combined new type reactive power generators are connected in parallel. Disclosed generator takes in and sends out large reactive components, compensates current. Features are: quick response, accurate control of voltage.

Owner:西安汇丰电力设备有限公司

Needle valve coupling of common rail oil injector

ActiveCN113107732ARealize dynamic compensationImprove work performanceFuel injection apparatusMachines/enginesPhysicsNeedle valve

The invention discloses a needle valve coupling of a common rail oil injector, and belongs to the technical field of oil injection systems. The needle valve coupling of the common rail oil injector comprises a needle valve, a needle valve body and an elastic module, wherein the needle valve is located in the needle valve body, a pressure chamber is formed between the interior of the needle valve body and the bottom of the needle valve, a plurality of oil injection holes are formed in the bottom of the needle valve body, the oil injection holes are formed in the circumferential direction of the pressure chamber, the elastic module is arranged at the bottom of the needle valve, a plurality of oil outlet holes distributed in the circumferential direction are formed in the periphery of the elastic module, a high-pressure oil channel is formed in the needle valve, an outlet of the high-pressure oil channel communicates with the oil outlet holes, a ball valve is arranged between the elastic module and the outlet of the high-pressure oil channel, and the ball valve is controlled to be opened or closed through the pressure of fuel oil in the high-pressure oil channel. In the lifting process of the needle valve, dynamic compensation of the fuel oil injection flow can be realized, so that the oil injection amount in unit time can be improved, meanwhile, the cavitation phenomenon inside an oil nozzle is relieved, and the service life of the oil injector is prolonged while the working performance of the oil injector is improved.

Owner:FAW JIEFANG AUTOMOTIVE CO

High-precision swing mirror follow-up mechanism

PendingCN109188680ACompact layoutSmall footprintPosition/direction controlOptical elementsEngineeringOptical tracking

The invention discloses a high-precision swing mirror follow-up mechanism. The follow-up mechanism comprises a base, a swing mirror arranged on the base, a driving mechanism arranged at the back partof the base, and an electric control unit at a side part of the base; a left rotating shaft system and a right rotating shaft system which are driven by the driving mechanism are further arranged on the base; the left rotating shaft system and the right rotating shaft system are connected through a swing rod; the swing mirror is fixed on the swing rod; a code disk connected with the swing rod is further arranged at the side part of the base; the driving mechanism is controlled by the electric control unit to drive the left rotating shaft system and the right rotating shaft system to rotate, and then the swing rod is driven to swing, so that the swing mirror swings; and optical tracking of the follow-up mechanism is obtained through a reading of the code disk. The mechanism can realize high-precision optical tracking, alignment and dynamic error measurement and compensation.

Owner:仝人智能科技(江苏)有限公司

Liquid crystal display and its brightness adjustment method and device

ActiveCN105336298BRealize dynamic compensationConsistent brightnessStatic indicating devicesLiquid-crystal displayComputer science

A liquid crystal display, and a luminance adjusting method and apparatus therefor. The luminance adjusting method for the liquid crystal display comprises: determining a pixel needing to undergo grayscale switching in a display panel of a liquid crystal display to be a to-be-processed pixel area; determining, according to a corresponding relationship between pixels in the display panel and backlight areas in a backlight source, a backlight area, corresponding to the to-be-processed pixel area, in the backlight source to be a to-be-dimmed area; and during a liquid crystal deflection period in which the pixel of the to-be-processed pixel area undergoes grayscale switching, adjusting the luminance of the to-be-dimmed area according to a grayscale value of the pixel of the to-be-processed pixel area. The liquid crystal display and the luminance adjusting method and apparatus therefor can dynamically compensate a relevant backlight area in a backlight source, thereby alleviating the phenomenon of trailing in liquid crystal display, such that the luminance presented on a display panel finally tends to be consistent, thereby achieving a better moving display effect.

Owner:ALIBABA (CHINA) CO LTD

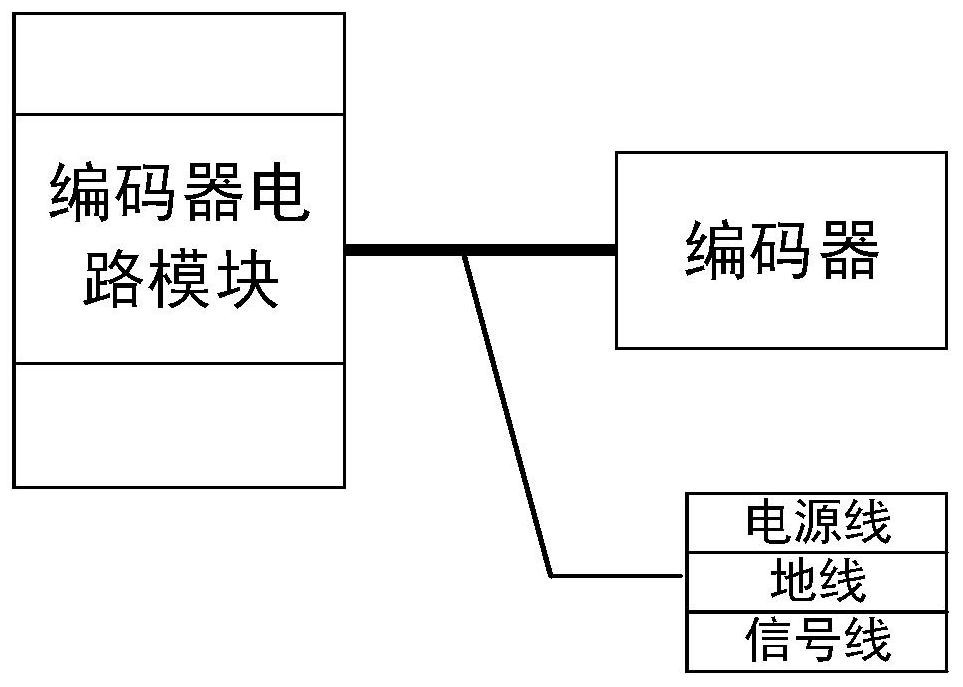

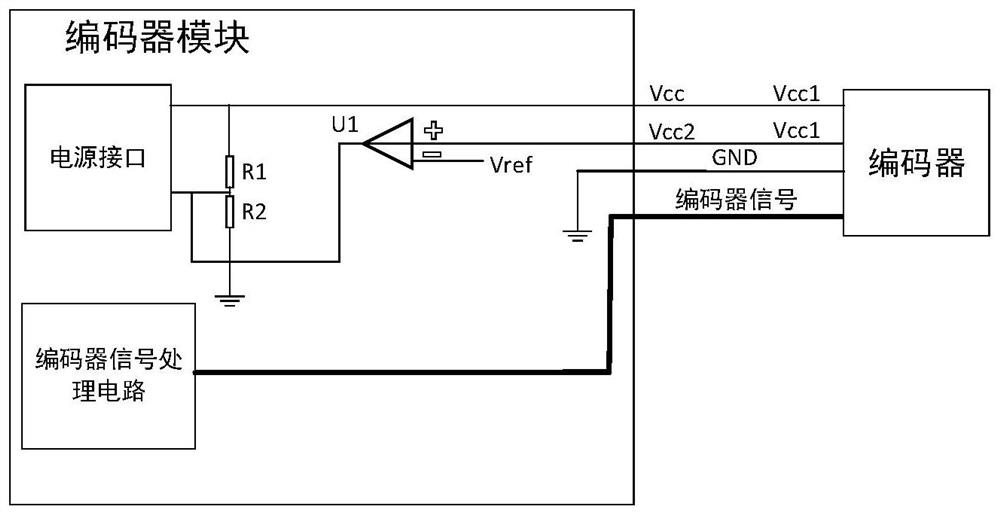

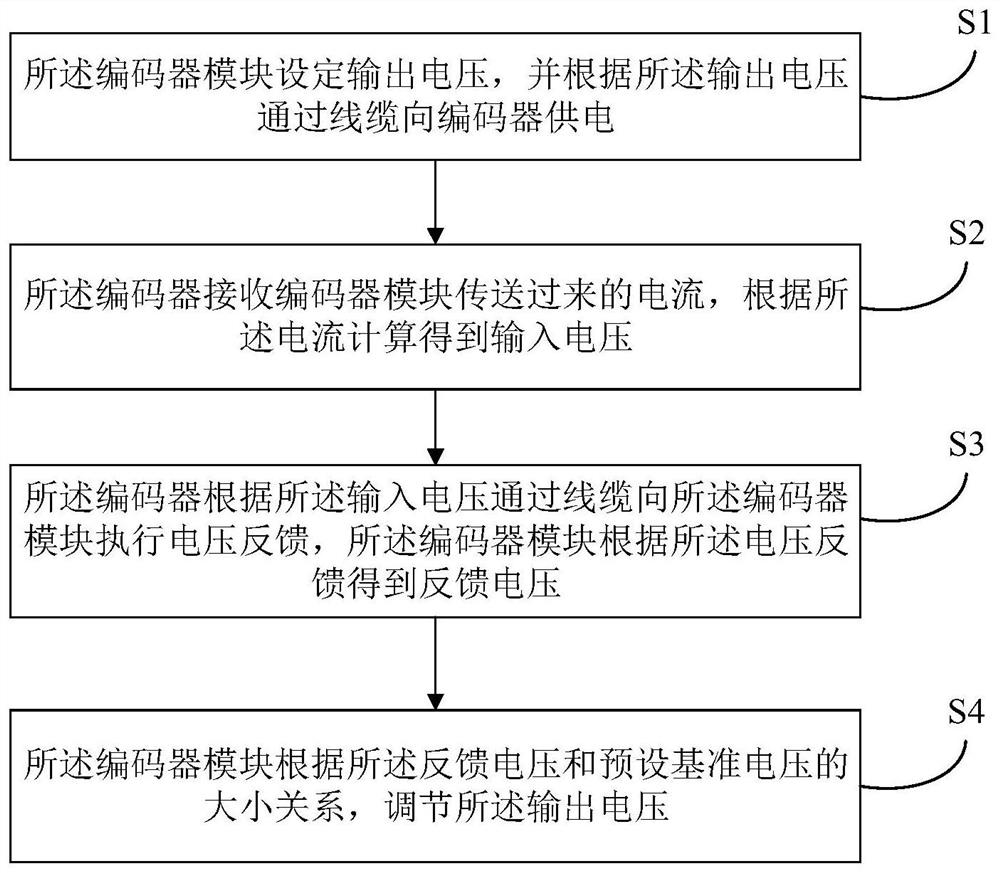

Encoder power supply dynamic compensation device and method

InactiveCN112286278ARealize dynamic compensationFlexible adjustment of output voltageElectric variable regulationHemt circuitsComputer science

The invention relates to the technical field of encoders, and discloses an encoder power supply dynamic compensation device and method. In the embodiment of the invention, the encoder power supply dynamic compensation device comprises an encoder circuit module and an encoder. The encoder circuit module and the encoder form a closed-loop circuit through a cable, and the closed-loop circuit comprises an output voltage provided by the encoder circuit module, an input voltage received by the encoder and a feedback voltage which is received by the encoder circuit module and generated by feedback executed by the encoder according to the input voltage. The encoder circuit module adjusts the output voltage of the closed-loop circuit according to the magnitude relationship between the feedback voltage and a preset reference voltage. Compared with the prior art, according to the embodiment of the invention, the output voltage of the encoder circuit module is flexibly adjusted by detecting the feedback voltage and controlling the closed-loop circuit, so that the dynamic compensation of the input voltage of the encoder is realized.

Owner:上海新时达机器人有限公司

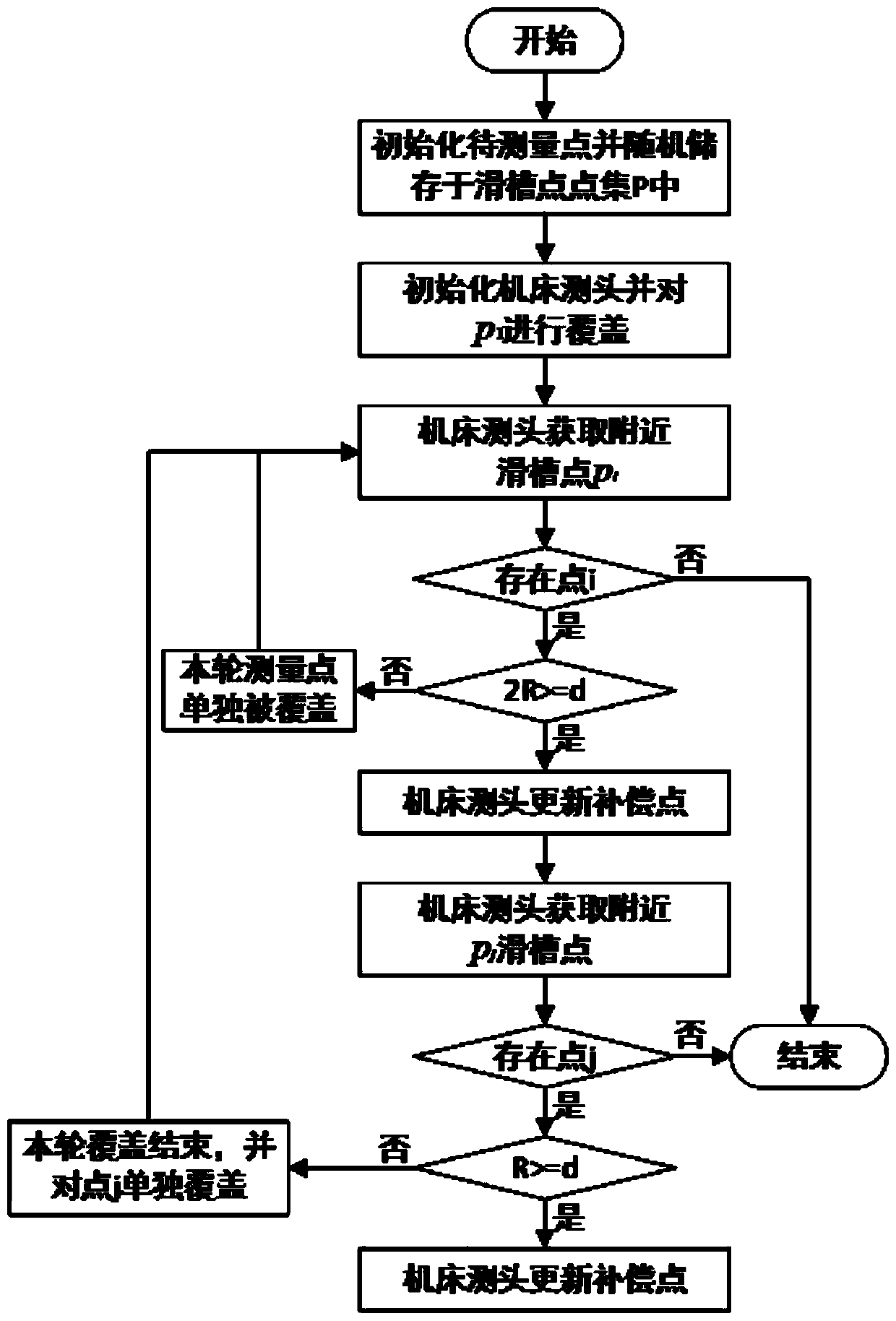

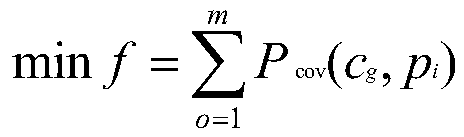

Method for measuring coverage of urban rail vehicle undercarriage

ActiveCN110208014AGood overallRealize dynamic compensationProgramme controlComputer controlManufacturing technologyMachine tool

The invention, which relates to the technical field of urban rail train manufacturing, specifically discloses a method for measuring the coverage of an urban rail vehicle undercarriage. According to the method, all chute points are stored into a chute point set; with a first to-be-measured chute point as a compensation point, a machine tool measuring head is controlled to carry out coverage; a to-be-measured chute point being closest to a current compensation point is obtained by the a machine tool measuring head; an Euclidean distance between the current compensation point and the nearest to-be-measured chute point is calculated; the calculated distance is compared with the diameter of a compensation area circle of the machine tool measuring head; the machine tool measuring head is controlled to carry out coverage by using the center of a connecting line between the current compensation point and the nearest to-be-measured chute point as a new compensation point; a to-be-measured chute point being closest to the new compensation point is obtained by the machine tool measuring head; an Euclidean distance between the current compensation point and the nearest to-be-measured chute point is calculated and the compared with the radius of the compensation area circle of the machine tool measuring head; and when the machine tool measuring head completes coverage of the chute point once each time, the coverage chute points are extracted from the chute point set until the chute point set becomes a null set and the operation is ended.

Owner:DALIAN JIAOTONG UNIVERSITY

Human eyes high order optical aberration orthopraxy method

InactiveCN100451734CRealize functionRealize dynamic compensationEye diagnosticsPhotomechanical exposure apparatusResistNear sightedness

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Freight train and speed tracking method and system thereof

PendingCN113859313AFast operationSave computing resourcesRailway signalling and safetyFreight trainsControl engineering

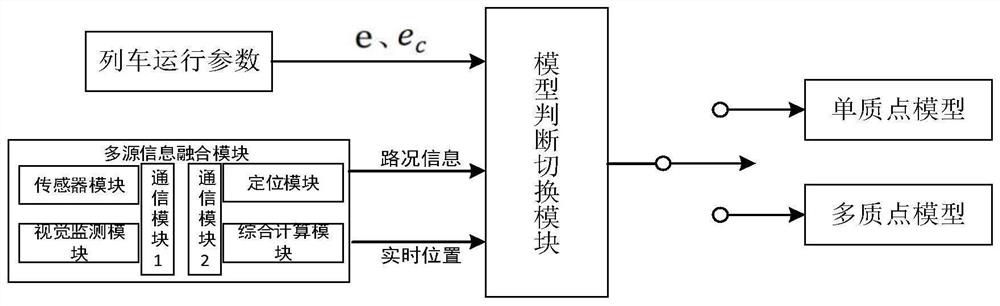

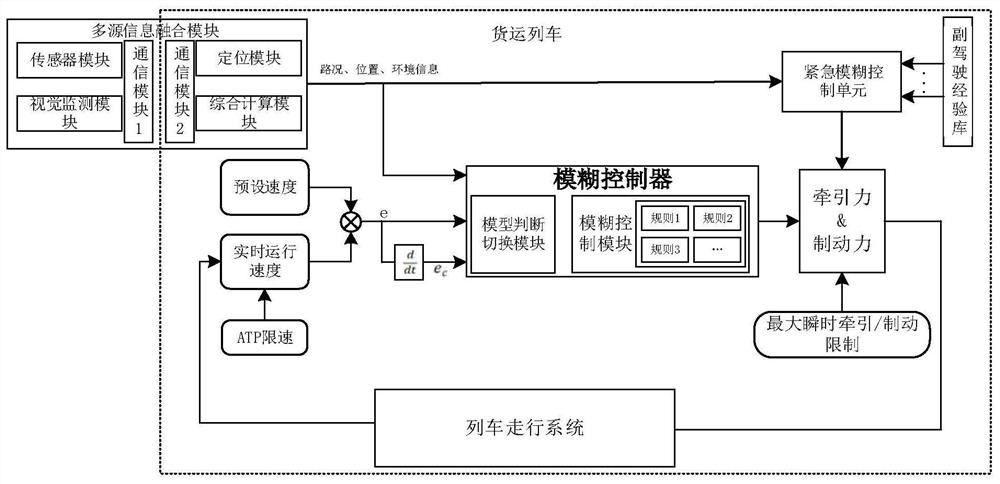

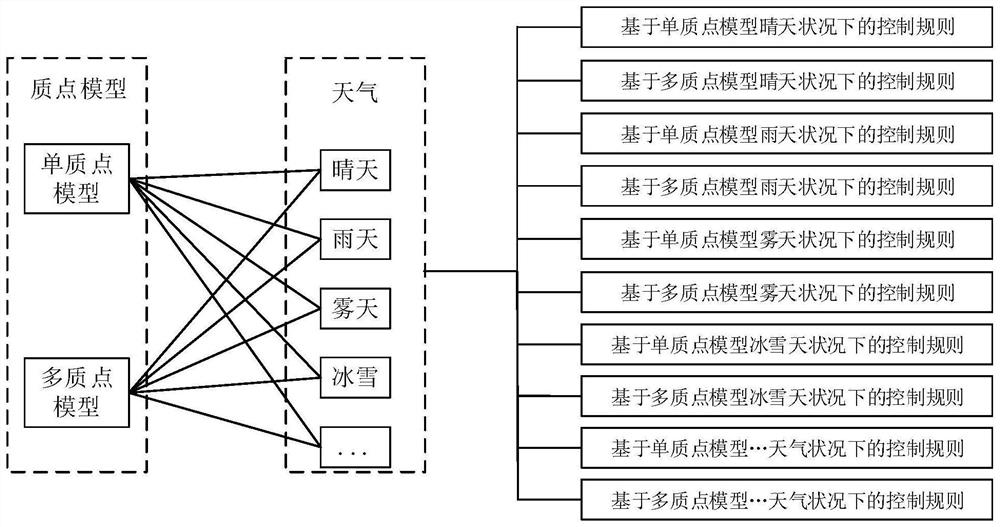

Disclosed are a freight train and the speed tracking method and a system thereof, switching of a simple substance point model or a multi-mass-point model is carried out according to road condition information and real-time positions, accurate control over a single carriage can be achieved by the multi-mass-point model on special road sections such as turning and uphill / downhill sections with gradient changes, and the speed of the freight train can be tracked through the multi-mass-point model. Rapid operation can be realized through a simple substance point model under most conditions of the whole operation line, operation resources are saved, and stable operation at the whole speed is realized; different operation environment information and the simple substance point model or the multi-mass point model correspond to different fuzzy control rules, in the actual operation process, the corresponding fuzzy control rules can be flexibly switched according to the operation environment and the control object, dynamic compensation is achieved, the operation control of the train is made to better meet the actual operation condition. And a better operation control effect is achieved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com