Needle valve coupling of common rail oil injector

A technology of common rail injector and needle valve, which is applied in the direction of engine components, machines/engines, fuel injection devices, etc., can solve the limited application scenarios, cannot improve the injector flow coefficient injector injection performance, and cannot effectively suppress Problems such as fuel injectors can be improved to achieve the effects of increasing fuel injection volume, realizing dynamic compensation, and reducing cavitation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

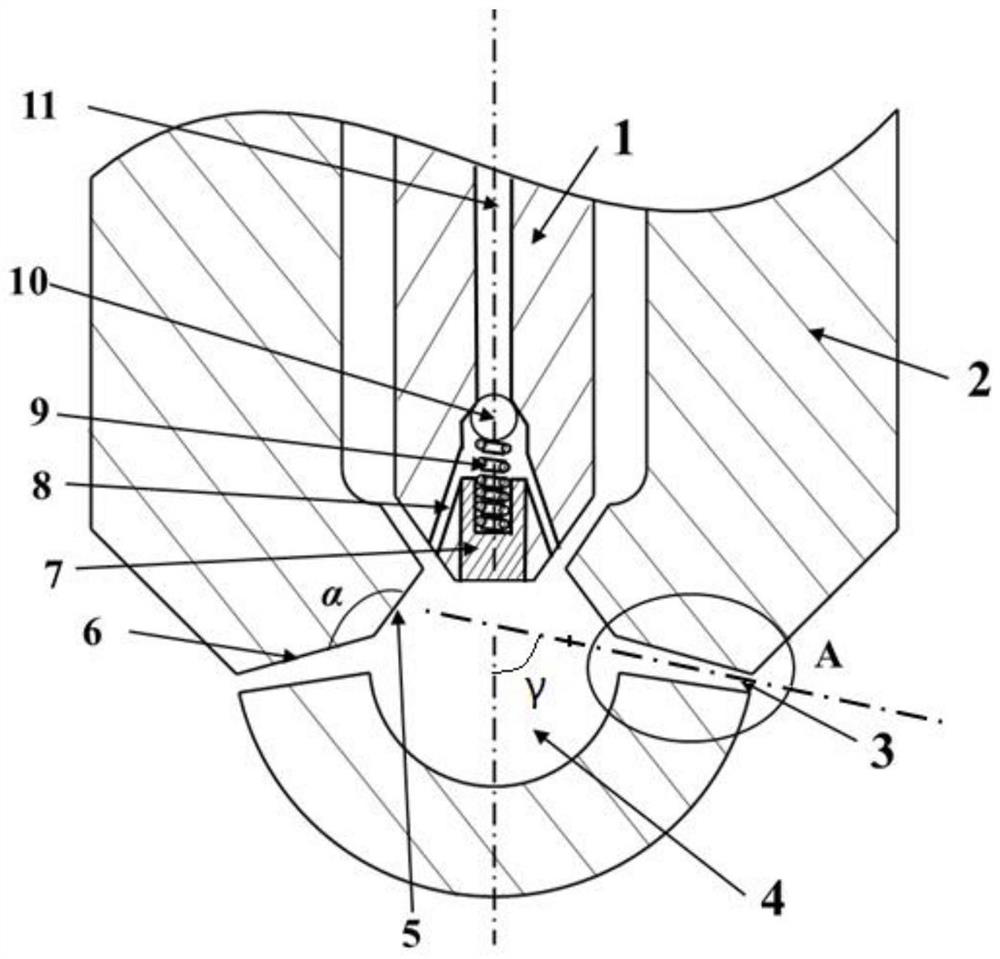

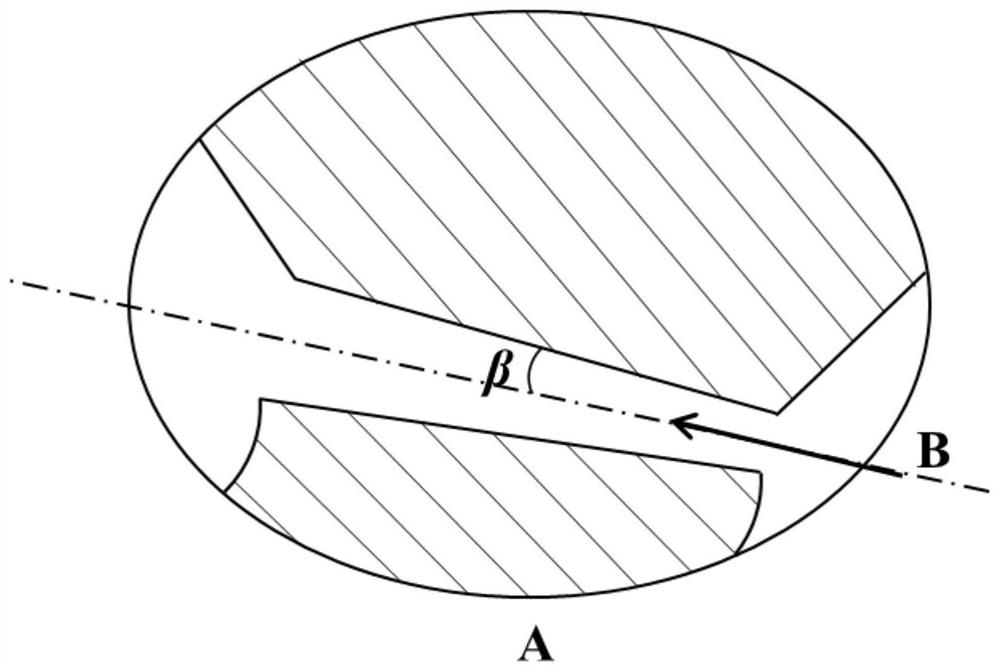

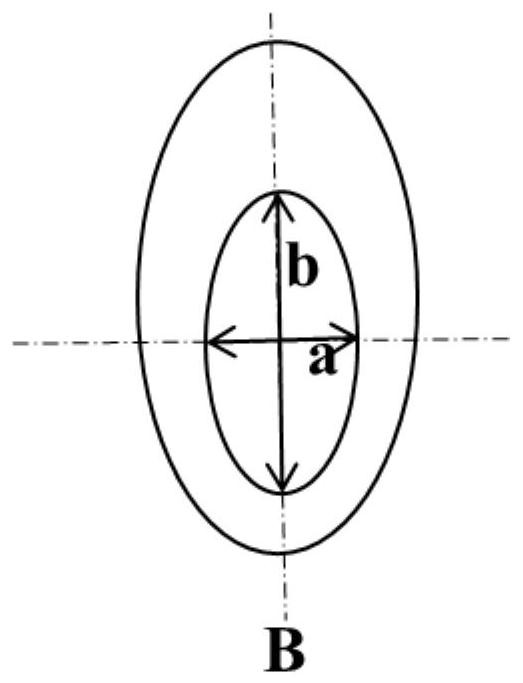

[0021] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0022] Let me explain in advance that the cavitation phenomenon is the process of the formation, development and collapse of vapor or gas cavities inside the liquid or on the liquid-solid interface when the local pressure in the liquid decreases. Due to the large pressure drop at the fuel injection hole of the traditional fuel injector, it is easy to cause cavitation. After the fuel injector is impacted by cavitation during the fuel injection process, the surface will be deformed and the material will be eroded, which will reduce the fuel injector. The flow coefficient affects the fuel injection characteristics, stability and service life of the fuel inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com