Method of secondary side connecting reactive power generator of smelting transformer

A technology for power generators and transformers, applied in the direction of reactive power adjustment/elimination/compensation, reactive power compensation, etc., can solve the problem of reducing reactive power and harmonic current, cannot achieve dynamic real-time compensation and local compensation, limited and other problems to achieve the effect of eliminating harmonic current and realizing asymmetric control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

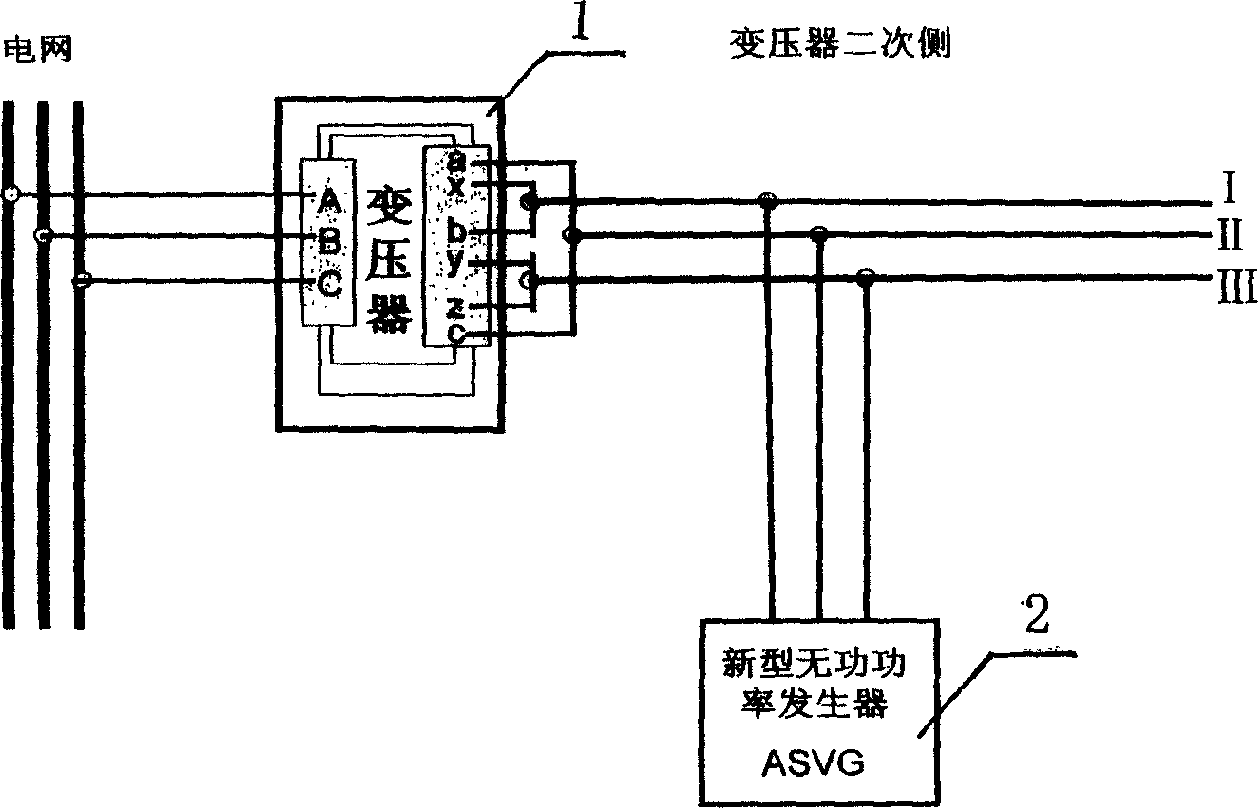

[0042] refer to figure 1 As shown, the smelting transformer 1 and the new reactive power generator 2 are included, and the new reactive power generator 2 is connected in parallel on the secondary side main circuit of the smelting transformer 1 .

[0043] The first end of the main circuit a-phase and c-phase winding of the secondary side of the smelting transformer is connected to phase II of the reactive power generator in parallel, and the first end of the main circuit b-phase winding is connected to the new type Phase I of the reactive power generator, three-phase secondary winding terminals y and z are connected in parallel to phase III of the new reactive power generator.

Embodiment 2

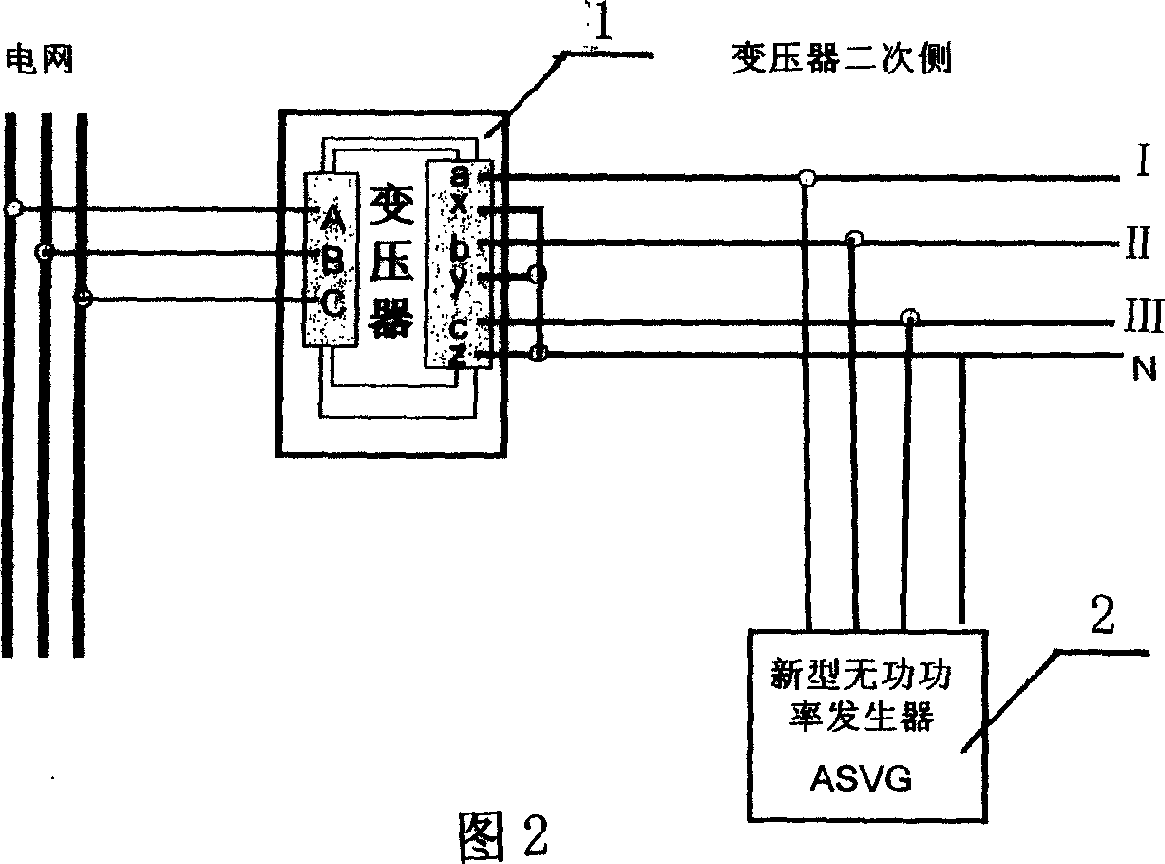

[0045] As shown in Fig. 2, including the smelting transformer 1 and the new reactive power generator 2, the three-phase four-wire circuit formed by the phase modulation of the first and the end of the three-phase main circuit winding on the secondary side of the smelting transformer 1 is connected in parallel with the new reactive power generator. Reactive Power Generator 2.

[0046] Phases a, b, and c of the main circuit are respectively connected to phases I, II, and III of the new reactive power generator in turn, and the terminals x, y, and z of the secondary winding of the three-phase four-wire system are connected in parallel to the new reactive power generator on the zero line N of device 2.

Embodiment 3

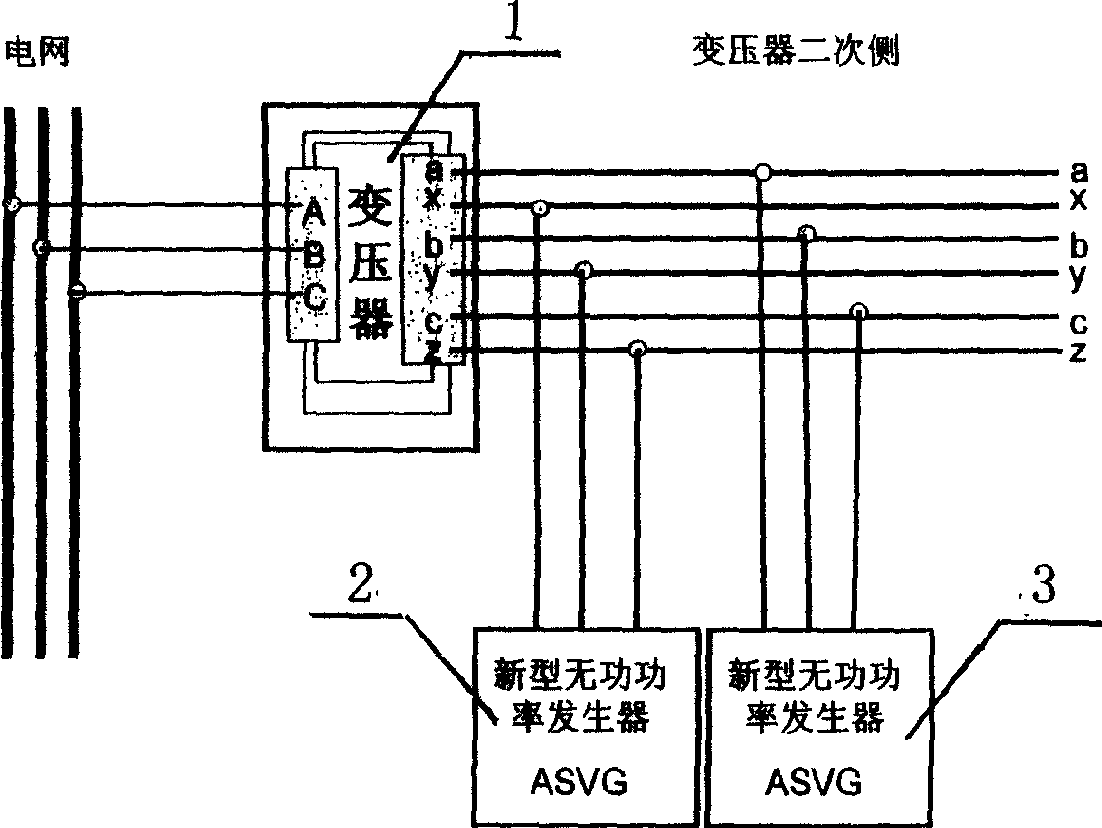

[0048] image 3 As shown, including the smelting transformer 1 and the new reactive power generator 2, the main circuit a, b, c phases and x, y, z are respectively connected in parallel with two sets of new reactive power generators 2; or the main circuits a-x, b-y, c-z formed by the non-phase adjustment of the first end and the end of the three-phase main circuit winding on the secondary side of the smelting transformer 1 are respectively on the single-phase A single-phase novel reactive power generator 2 is connected in parallel.

[0049]Including the AC smelting transformer 1 and the new reactive power generator 2, on the secondary side of the smelting transformer 1, the three-phase main circuit a, b, c three-phase secondary winding head end and the three-phase secondary winding end x, y Two new reactive power generators 2 and 3 of the same model are respectively connected in parallel on z and z respectively.

[0050] Or the first end of the three-phase main circuit a, b,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com