Dynamic compensation mechanism for bottom dead center of high-speed precise press

A dynamic compensation and press technology, applied in the field of presses, can solve the problems of difficult to achieve bottom dead center dynamic compensation, affecting the quality of stamping parts, die life, thread failure, etc., to improve quality and die life, large bearing capacity, friction Low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

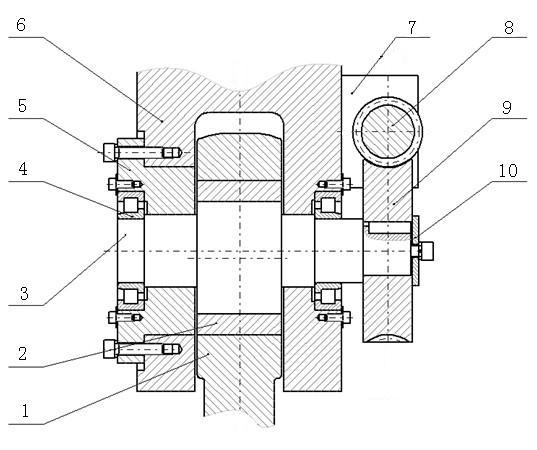

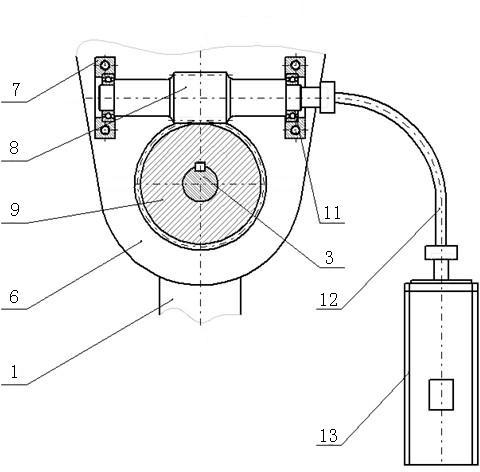

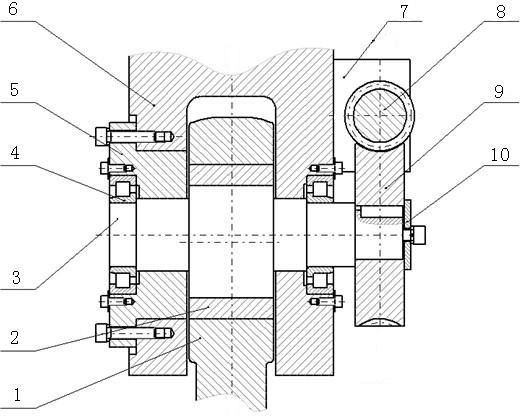

[0015] Such as figure 1 and figure 2 As shown, a dynamic compensation mechanism for the bottom dead point of a high-speed precision press includes a shaft 3 mounted on a connecting rod 6 through two cylindrical roller bearings 4 and a shaft seat 5. The shaft 3 is an eccentric structure in the middle. One end of 3 is equipped with a worm 8 and a worm wheel 9 mechanism, the worm 9 is connected with the shaft 3, the worm 8 is fixed on the connecting rod 6 through the bearing seat 7 and connected with the servo motor 13 through the elastic flexible shaft 12, and the servo motor 13 is fixed on on the press body.

[0016] The eccentric part of the shaft 3 is connected with the central shaft 1 through the central bearing shell 2, and the transmission of the shaft 3 drives the central shaft 1 to rise or fall, and then drives the moving parts of the slider to rise or fall, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com