Automatic load-variable multi-variable control method for air separation device

A multi-variable control, air separation plant technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem of inability to adjust, increase the difficulty of air separation variable load operation, and be difficult to control the air separation variable load And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

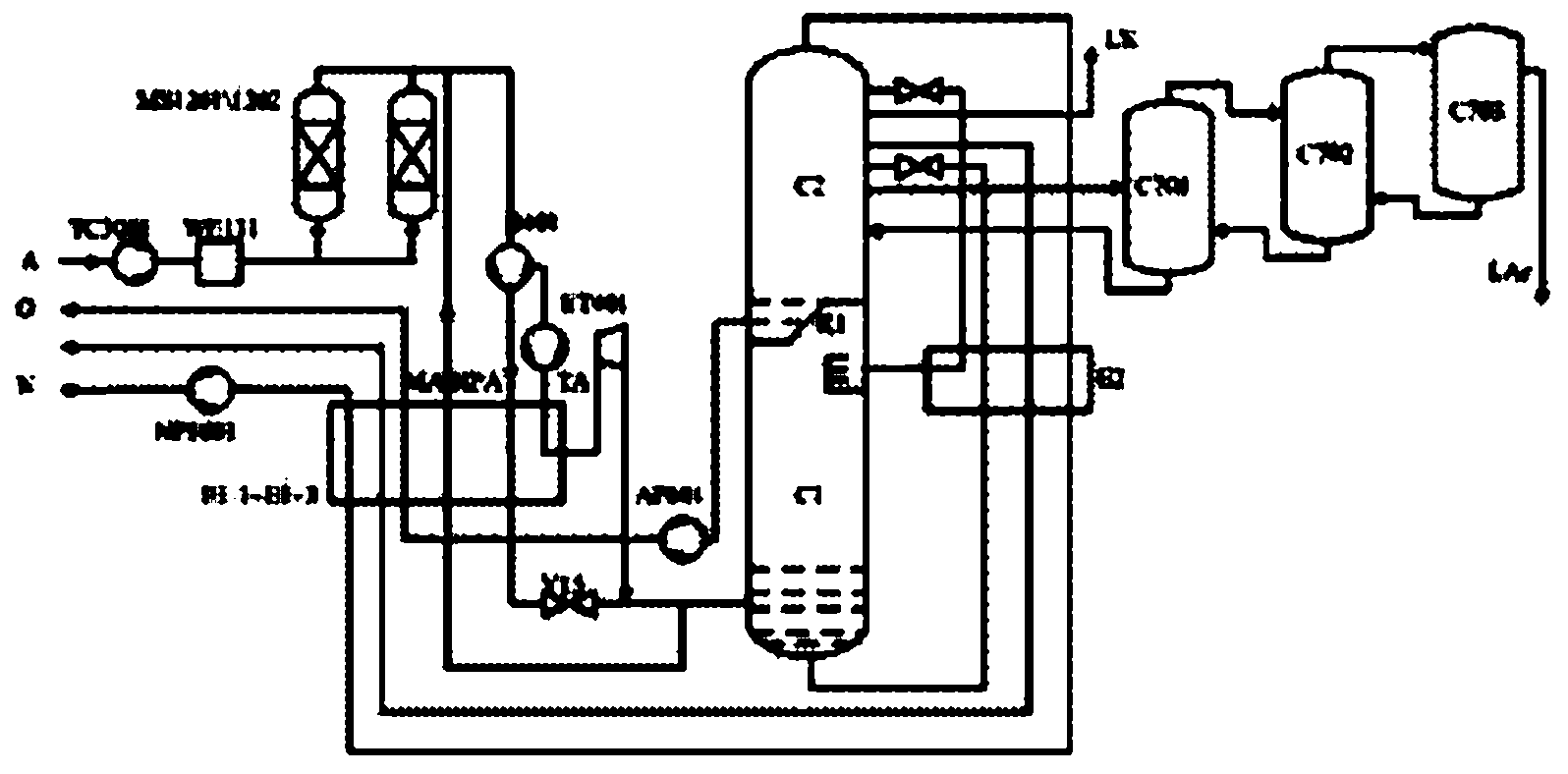

[0045] The present invention is a kind of automatic variable load multi-variable control method of air separation unit, and it forms an organic system by following three major modules:

[0046] Module 1. Gain scheduling based on the operating trajectory LPV (linear parameter varying) model;

[0047] Module 2. Predictive control system based on LPV gain scheduling;

[0048] Module 3, dynamic real-time optimization (RTO, real time optimization) module;

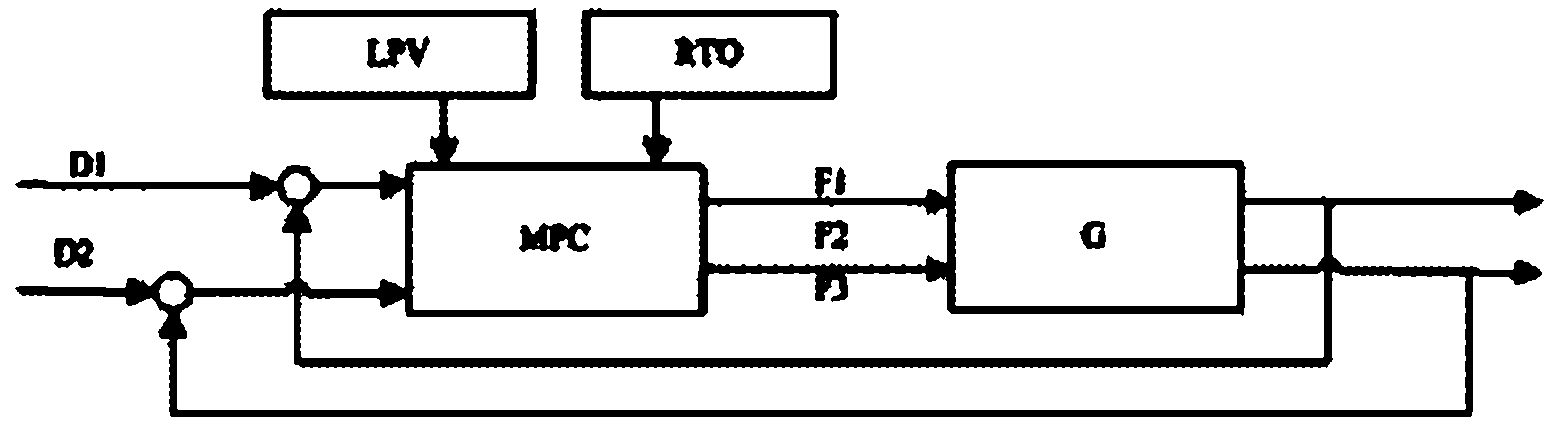

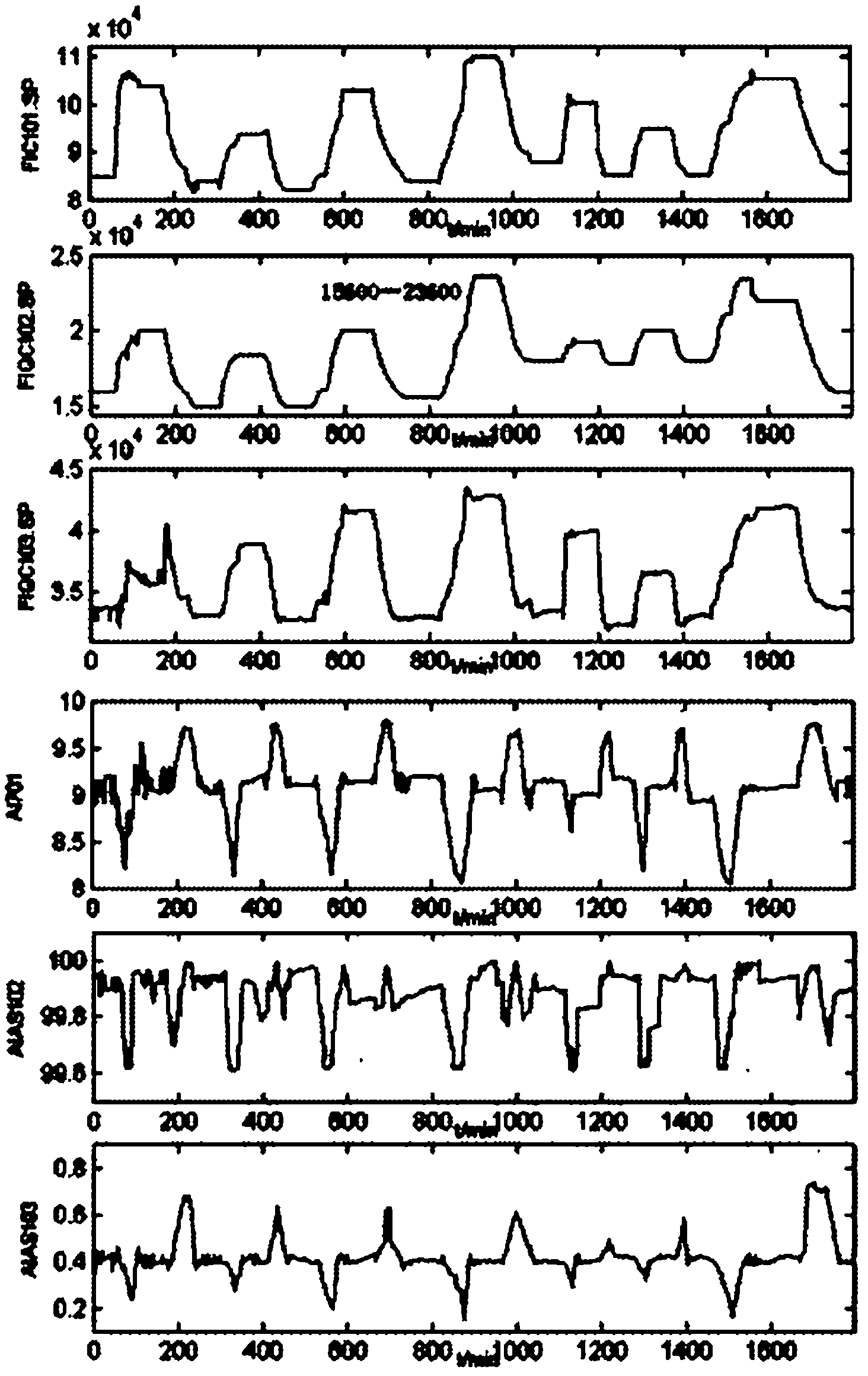

[0049] The principle structural diagram of the automatic variable load multivariable control method of the air separation plant of the present invention is as follows figure 2 As shown, the RTO module calculates the optimal steady state of the process variables (including high-pressure air flow, main passage air flow, expansion air flow, liquid oxygen flow and nitrogen flow) related to load changes according to the variable load requirements of the device The value is sent to the industrial MPC with a large controller structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com