Laser Thermal Effect Compensation System

A compensation system and thermal effect technology, applied in the field of optoelectronics, can solve the problems of high cost, change of cavity structure, and difficult tuning, etc., and achieve the effect of low cost, simple tuning and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

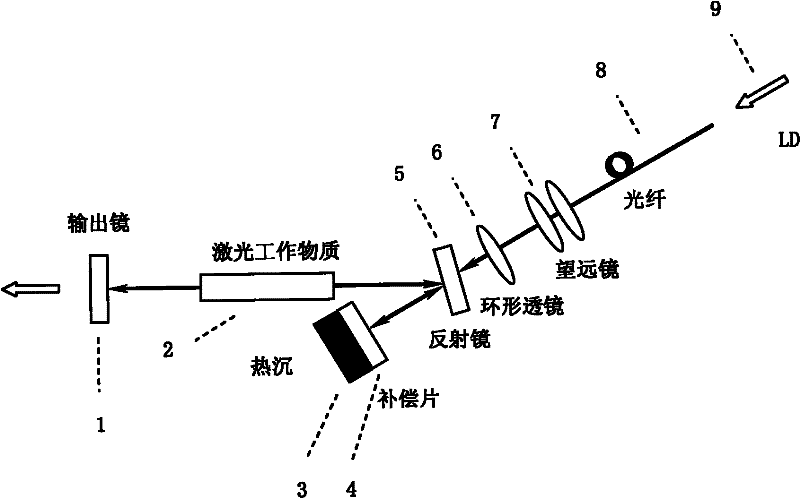

[0030] The following is attached figure 1 with 2 Embodiments of the present invention will be further described.

[0031] figure 1 The middle ring lens (6) converts the transmitted light of the LD (9) through the optical fiber (8) and the telescope (7) into a ring beam; it can be changed by replacing the ring lens with a different focal length or adjusting the distance between it and the telescope or the compensation sheet (4). Relative to the distance, adjust the size of the light spot it hits on the compensation sheet;

[0032] The mirror (5) is coated with a high-reflectance coating (High-reflectance Coating, HR Coating) for the laser beam on one side facing the resonator, and both sides are coated with an anti-reflection coating (Anti-reflectance Coating, AR Coating) for the beam emitted by the LD;

[0033] The compensator material itself is completely transparent to the laser beam, and has a high absorption rate (for example, greater than 90%) for the LD beam; and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com