Real-time detection system for weld surface defect video and detection method of real-time detection system

A real-time detection and weld surface technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of unsatisfactory detection results and complex detection methods, and achieve the effect of improving detection accuracy, compact structure, and satisfying detection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

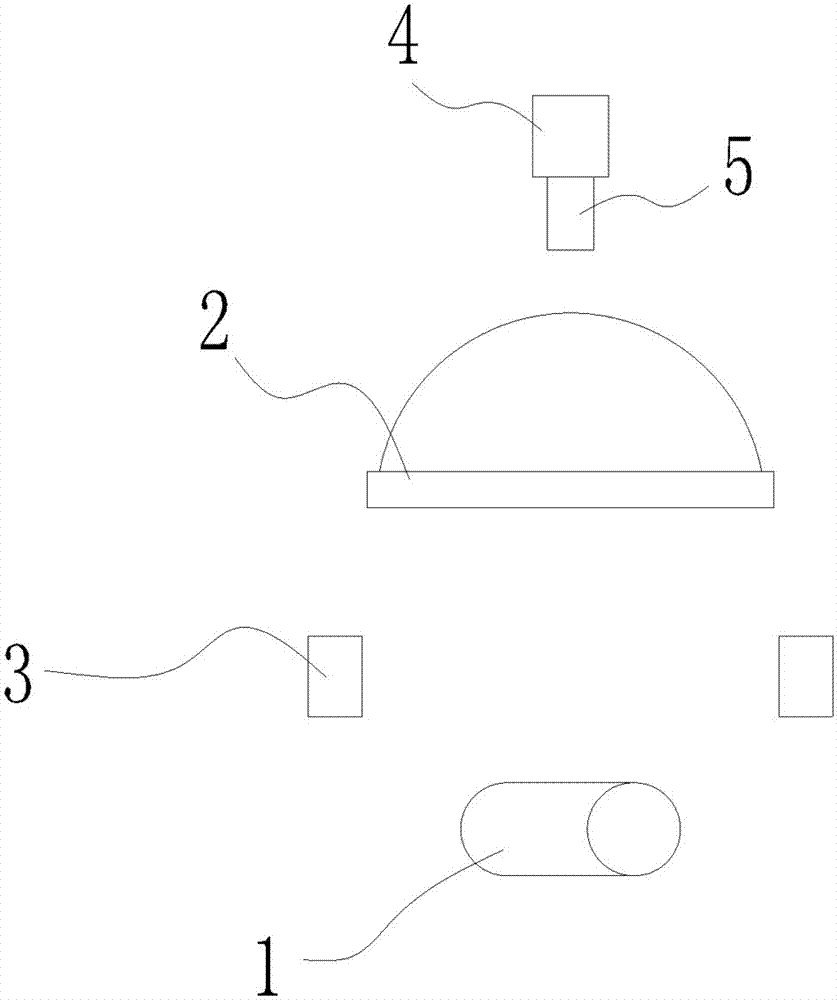

[0020] Example 1: as figure 1 As shown, a video real-time detection system for weld surface defects includes a detection object 1, a lens assembly, a ring light source 2 and a bar light source 3, the lens assembly includes a camera 4, and the camera 4 is provided with lens 5;

[0021] The lens 5 is located above the ring light source 2 , the strip light source 3 is located below the ring light source 2 , and the detection object 1 is located in the middle of the bottom of the strip light source 3 .

[0022] The distance between the lens 5 and the ring light source 2 is 100-120mm, the width of the ring light source 2 is 180-220mm, the width of the strip light source is 60-100mm, the ring light source and the strip light source are 100-120mm wide. The distance between the light sources is 80-100mm, and the distance between the strip light source and the detection object is 40-60mm.

[0023] A detection method for a video real-time detection system for weld surface defects is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com