Automatic shrimp shelling device capable of separating and collecting shrimp shells and shrimp meat

A collection device and shrimp peeling technology, which can be used in shrimp/lobster processing, crustacean processing, slaughtering, etc., and can solve the problems of waste, falling in, falling out of shrimp or shrimp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiment of the automatic shrimp peeling device for separating and collecting shrimp shells and shrimp meat of the present invention will be further described below in conjunction with the accompanying drawings.

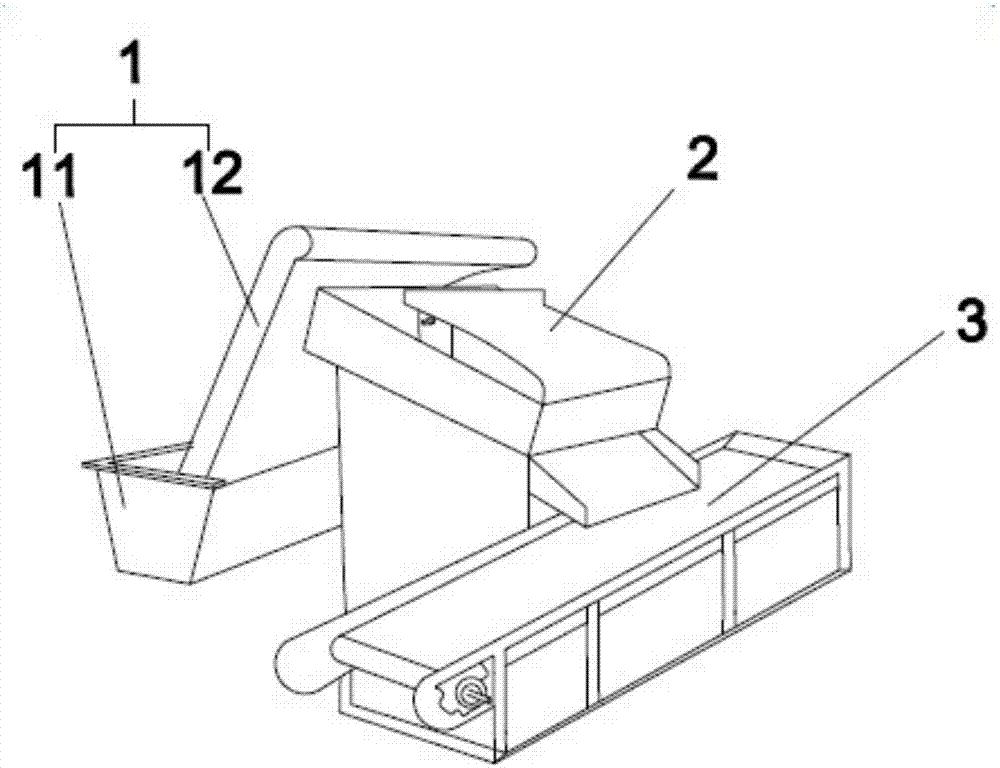

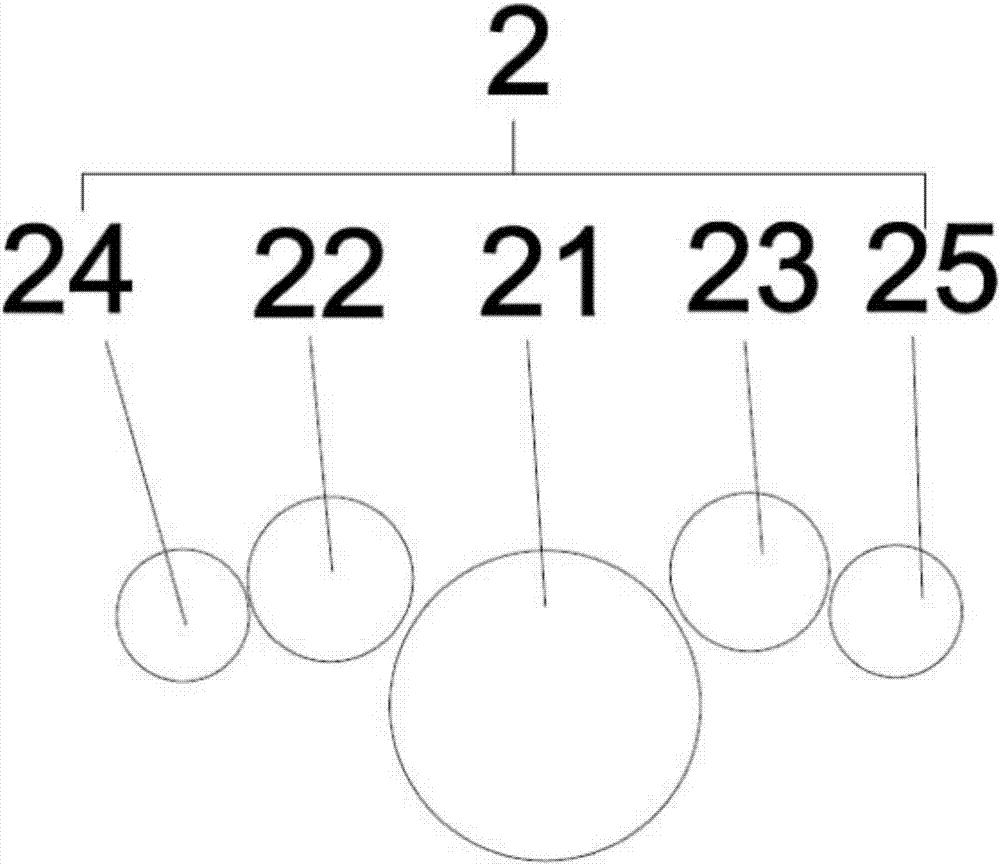

[0016] An automatic shrimp peeling device that separates and collects shrimp shells and shrimp meat, including a shrimp feeding mechanism 1, a shrimp peeling mechanism 2, and a collecting mechanism 3. The shrimp peeling mechanism 2 includes a large roller 21, two small rollers and two hairs The brush roller, the big roller 21 rotates reciprocally, the two small rollers are the left roller 22 and the right roller 23 respectively, the left roller 22 is located at the upper left of the large roller 21, and the right roller 23 is located at the bottom of the large roller 21 On the upper right, the rotation directions of the left roller 22 and the right roller 23 are opposite and both face the big roller 21, and the distance between them and the big roller 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com