Preparation method of tomato hot pot bottom material

A technology of hot pot bottom material and tomato, which is applied to the functions of food ingredients, food ingredients as antimicrobial preservation, food ingredients as antioxidants, etc. It can solve the problems of high technical requirements for operation and low efficiency, and avoid splashing around, The effect of increasing appetite, appetizing and invigorating spleen appetite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Taking embodiment 1 as an example, its specific implementation method:

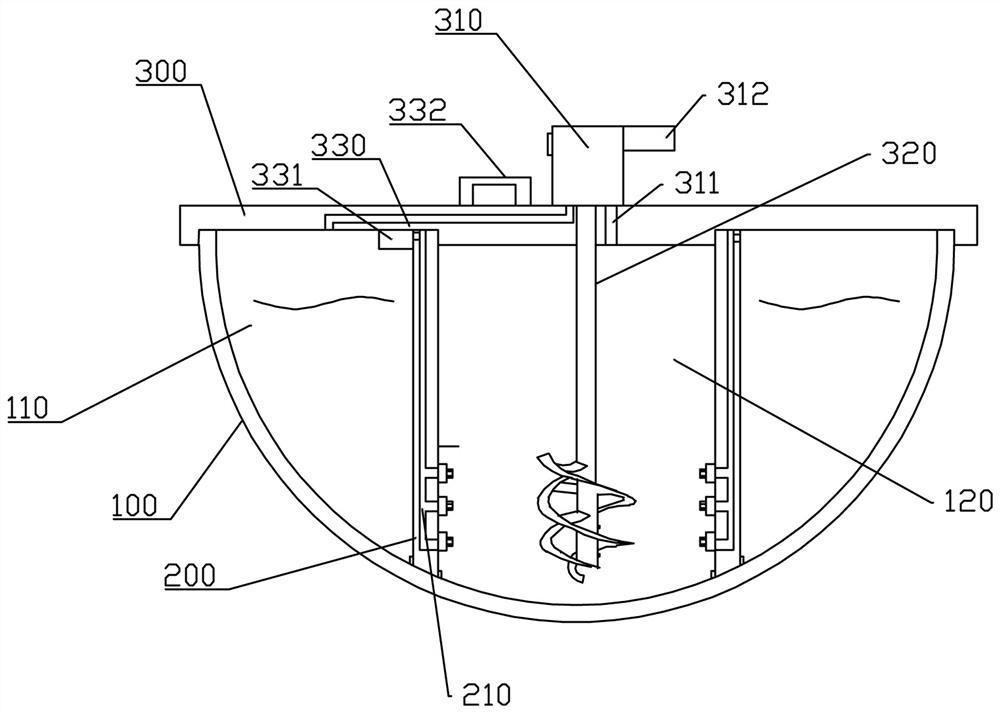

[0026] The method is carried out using the following equipment, such as figure 1The stir frying pot shown includes a pot body 100, a partition 200 and a pot cover 300. The pot body 100 is provided with a slot connected to the partition 200, and the pot body 100 is separated by the partition 200 into an outer poaching area 110. With the frying area 120 inside, the pot cover 300 seals the opening of the pot body 100, the pot cover 300 is clamped to the partition 200, the partition 200 is provided with an air jet channel 210, and the inlet of the air jet channel 210 is arranged on the upper part of the outer side of the partition plate 200, The outlet of the jet channel 210 is arranged at the lower part of the inner side of the partition 200. The pot cover 300 includes a cover body 330, a stirring shaft 320 and an air outlet head 310. The air outlet head 310 is arranged on the upper end of the cover b...

Embodiment 2

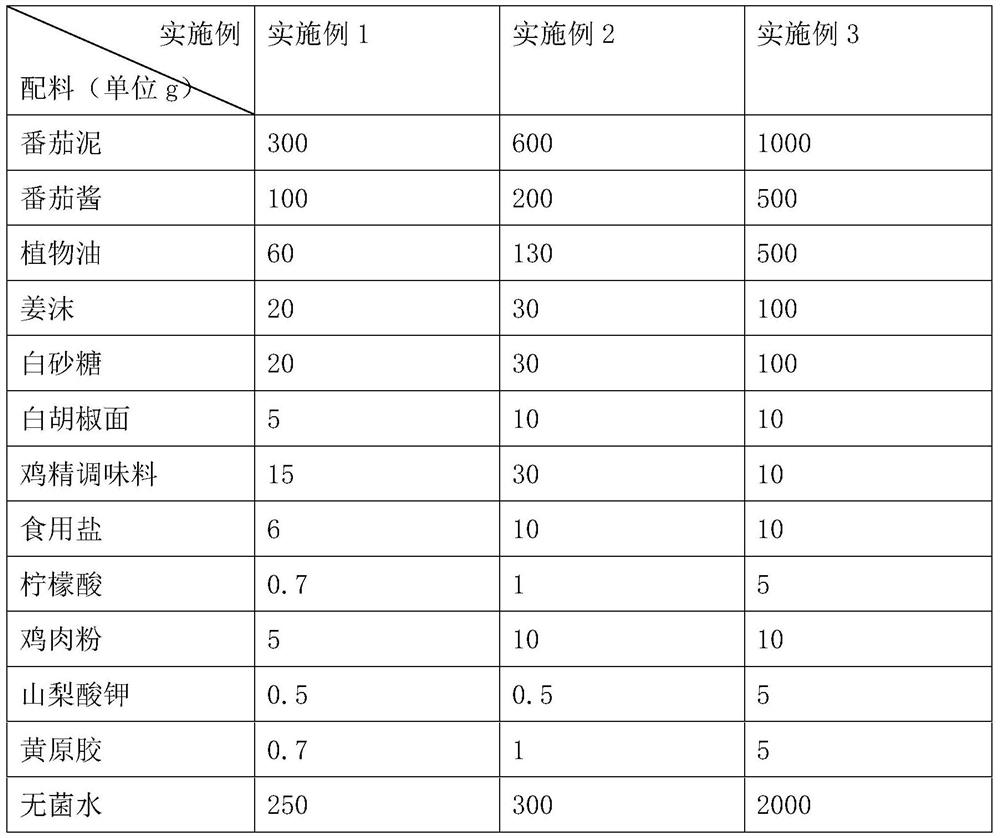

[0028] The difference between Example 2 and Example 3 and Example 1 lies in the difference of the component parameters in Table 1.

[0029] experiment:

[0030] Experimental method (single-blind method):

[0031] Divide 30 tasters into 3 tables, 10 people per table, one table has two pots, No. 1 pot and No. 2 pot, and no other markings will be made. Choose 18:00-22:00 on the same day, the dishes are the same, and the person who tastes before the meal does not know which pot has the bottom of the pot made by the method of embodiment 1.

[0032] Pot No. 1: The hot pot base is prepared from step 1, the hot pot base is 500g, and water is 2L;

[0033] Pot No. 2: commercially available tomato hot pot base, hot pot base 500g, water 2L;

[0034] Experimental results: 1. The experimental results showed that 26 testers thought that the taste of the No. 1 pot was better, and 4 testers thought that the taste of the No. 2 pot was better.

[0035] 2. After the test, measure the acid val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com