Novel spanner capable of replacing wobblers of spanner

A technology of torx head and wrench, which is applied in the field of ratchet wrench, can solve the problems that the ratchet wrench cannot replace the torx sleeve, is inconvenient for daily use, and has low practicability, and achieves the effects of simple structure, shortened service life and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

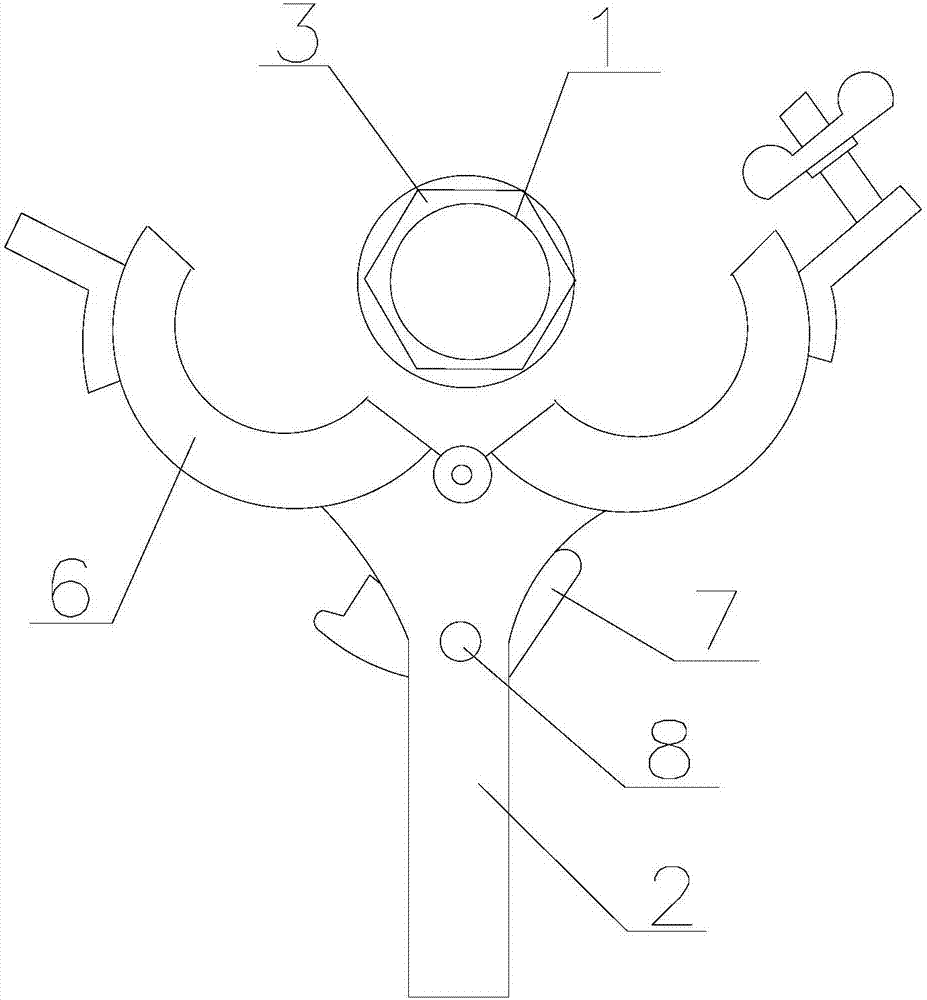

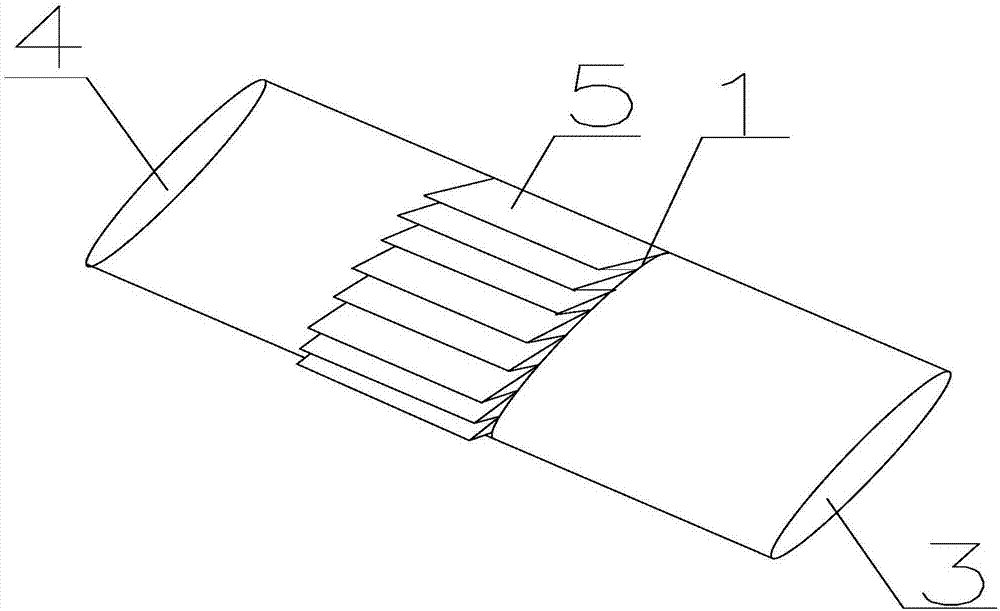

[0024] Such as Figure 1-3 As shown, the novel wrench of the present invention that can replace the wrench torx head includes a slave torx cover, a main torx cover, a handle 2 connected to the main torx cover, the main torx cover is used to fix the slave torx cover, and the main torx cover is composed of Two semi-cylinders 6, connecting hinge, support hinge seat, support hinge pin, support hinge screw rod, compression nut and compression buckle are composed, and the described plum blossom sleeve includes a circle whose diameter is the same as that of the circle formed by the two semi-cylinders 6. Fixed ring 1, the two sides of described fixed ring 1 are respectively connected with quincunx-shaped through-hole A3 and quincunx-shaped through-hole B4, and the diameter of described quincunx-shaped through-hole A3 is greater than the diameter of quincunx-shaped through-hole B4, and described fixed circle There is a ratchet 5 on the surface of the ring 1, and the fixed ring 1 of the...

Embodiment 2

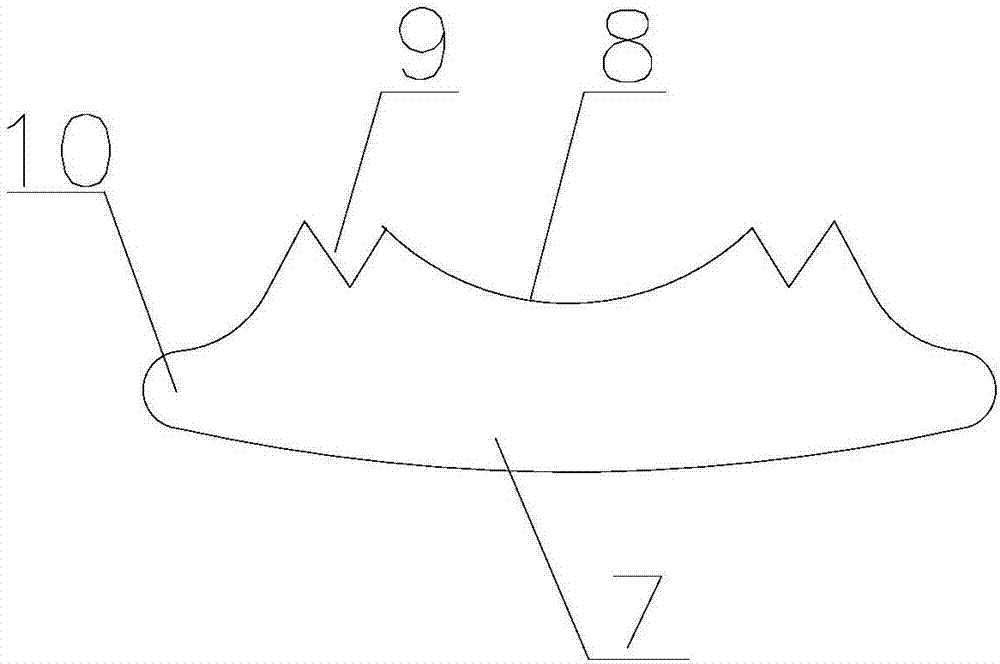

[0026] The new wrench with replaceable torx head of the wrench includes a slave torx sleeve, a main torx sleeve, and a handle 2 connected to the main torx sleeve. The main torx sleeve is used to fix the slave torx set. It is composed of half cylinder 6, connecting hinge, support hinge seat, support hinge pin, support hinge screw rod, compression nut and compression buckle. ring 1, the two sides of the fixed ring 1 are respectively connected with a quincunx-shaped through hole A3 and a quincunx-shaped through-hole B4, the diameter of the quincunx-shaped through-hole A3 is greater than the diameter of the quincunx-shaped through-hole B4, and the fixed ring 1 There is a ratchet 5 on the surface, and the fixed ring 1 of the secondary torx sleeve is fixedly connected between the two semi-cylinders 6 of the main torx sleeve; there is a through hole on the handle 2, and the pin shaft 8 is passed through the through hole. A positioning key 7 is connected to it, and the positioning key...

Embodiment 3

[0028] The new wrench with replaceable torx head of the wrench includes a slave torx sleeve, a main torx sleeve, and a handle 2 connected to the main torx sleeve. The main torx sleeve is used to fix the slave torx set. It is composed of half cylinder 6, connecting hinge, support hinge seat, support hinge pin, support hinge screw rod, compression nut and compression buckle. ring 1, the two sides of the fixed ring 1 are respectively connected with a quincunx-shaped through hole A3 and a quincunx-shaped through-hole B4, the diameter of the quincunx-shaped through-hole A3 is greater than the diameter of the quincunx-shaped through-hole B4, and the fixed ring 1 There is a ratchet 5 on the surface, and the fixed ring 1 of the secondary torx sleeve is fixedly connected between the two semi-cylinders 6 of the main torx sleeve; there is a through hole on the handle 2, and the pin shaft 8 is passed through the through hole. A positioning key 7 is connected to it, and the positioning key...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com