Gripping mechanism for waste filtering core replacement and transfer unit device

A technology of unit device and grasping mechanism, applied in the directions of transportation and packaging, conveyor objects, etc., can solve problems such as being susceptible to radiation, and achieve the effect of improving safety and improving safety level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

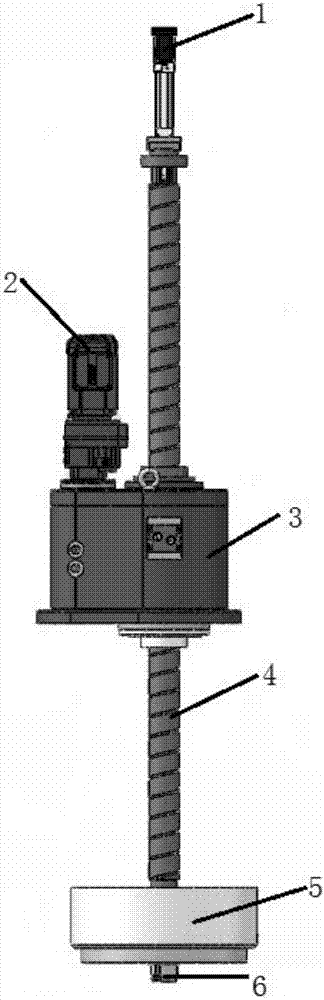

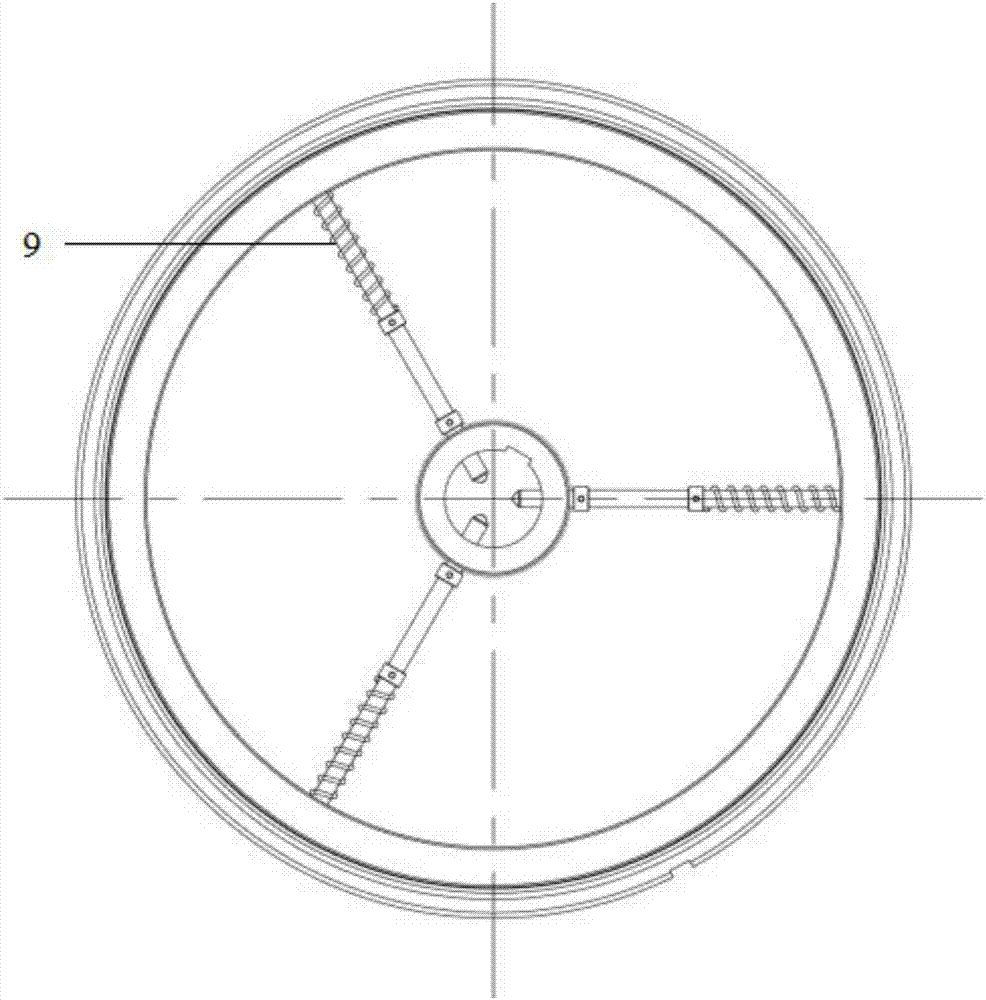

[0024] This embodiment provides a grasping mechanism for a waste filter element replacement transfer unit device, including: a grasper electric cylinder, a reduction motor, a transmission gearbox, a lead screw, a sealing ring, and a grasper claw; the lead screw passes through the transmission gear There is a gripper electric cylinder on the top of the lead screw, and a sealing ring at the bottom. The gripper claw is placed under the sealing ring, and the deceleration motor is installed on the transmission gear box, which can remotely control the movement of the lead screw Lifting, the transmission gearbox is fixed on the waste filter element replacement transfer unit device.

[0025] Preferably, the transmission gearbox is provided with a transmission mechanism overload protector and a safety nut; the transmission mechanism overload protector prevents the reduction motor from being overloaded and fails, and the safety nut prevents the lead screw from falling due to long-term we...

Embodiment 2

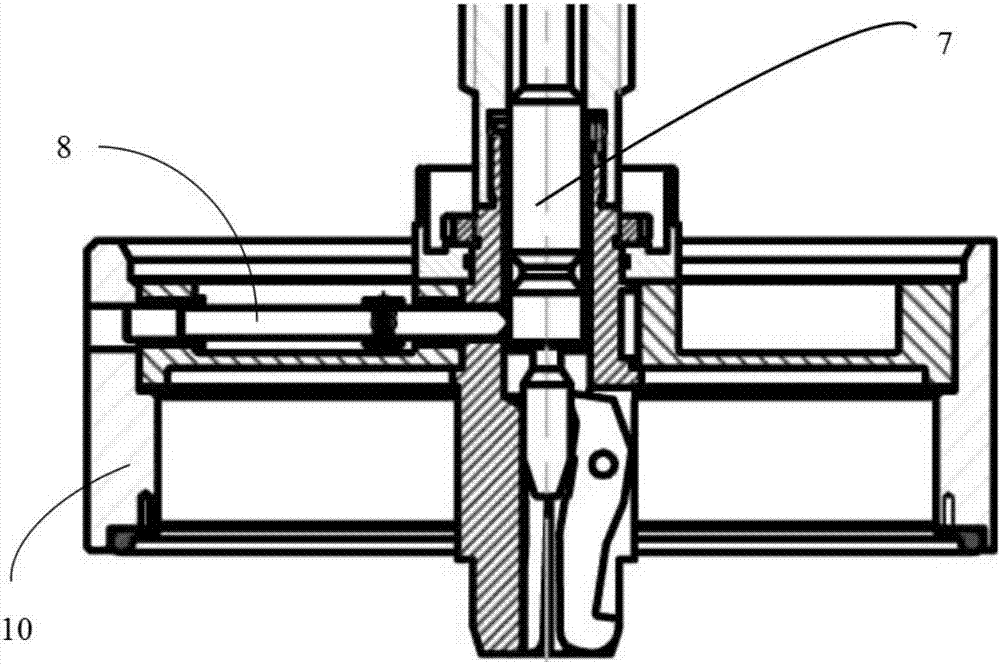

[0027] As a further supplement to Embodiment 1, the application provides a sealing ring, including a sealing disc and a shielding container ring, and the shielding container ring is respectively connected with the waste filter element replacement transfer unit device and the filter element chamber to play a sealing role; the sealing disc There is a pin hole on the side, and the pin rod is fixed by a compression spring. One end is against the connecting rod inside the lead screw, and the other end passes through the pin hole to block the shielding container ring. The electric cylinder of the gripper is connected to one end of the connecting rod inside the lead screw. The other end of the connecting rod is against the claw of the gripper and has a V-groove matching the size of the pin rod. The shielding container ring falls automatically when the claws of the gripper grab the lid of the shielding container, and is automatically retracted when the claws of the gripper break away f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com