A stacking device for corrugated cardboard

A corrugated cardboard and finishing device technology, which is applied in stacking receiving devices, thin material handling, transportation and packaging, etc., can solve the problems of uneven heat dissipation, inconvenient board taking, damage, etc. Utilization, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

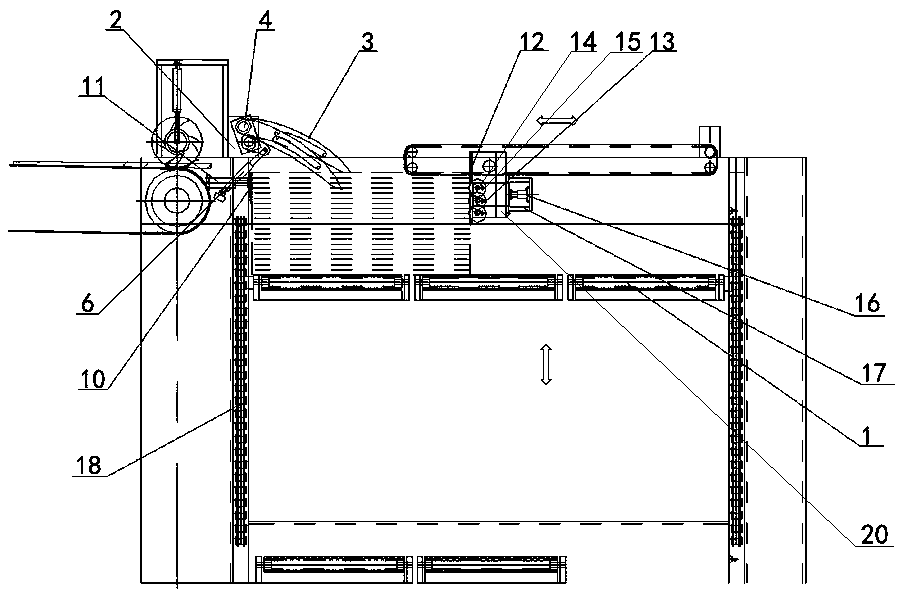

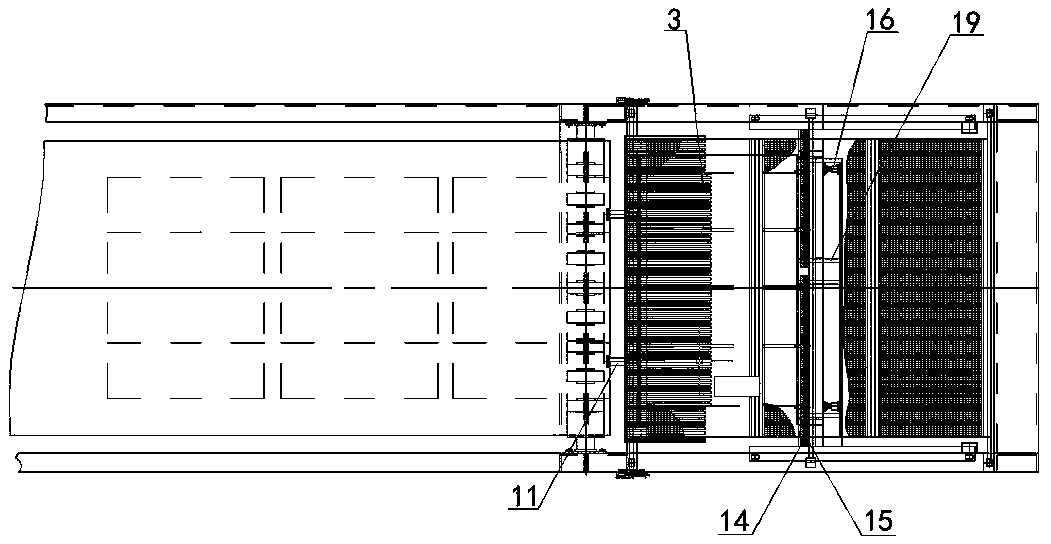

[0022] As shown in the figure: a stacking and sorting device for corrugated cardboard, including a stacking lifting platform 1, a paper pressing mechanism set at the feeding end of the stacking lifting platform 1, a clapping and sorting mechanism set under the paper pressing mechanism, and a The front baffle mechanism at the end opposite to the paper pressing mechanism on the stacking lifting platform 1 and the cardboard separation mechanism arranged on the front baffle mechanism, the stacking lifting platform 1 moves up and down through the lifting chain 18, and the bottom of the stacking lifting platform 1 is set Conveyor assembly for moving corrugated cardboard out of the stacker lift 1.

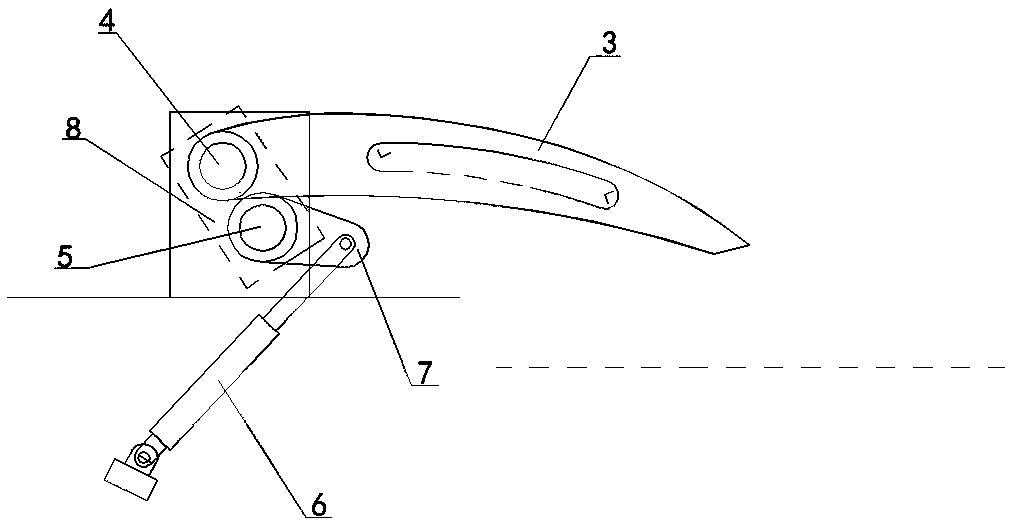

[0023] The press mechanism includes a support plate 2, a press plate 3, a rotating shaft 4, a retaining shaft 5, and a press cylinder 6 for driving the retaining shaft 5 to rotate. The shaft 5 is set between the two supporting plates 2, and the two ends of the blocking shaft 5 protrude fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com