Packaging box room and point angle piece thereof

A technology of vertices and box houses, which is applied in the direction of construction and building construction, can solve the problems of inconvenient installation, waste of materials, increase of production and transportation costs, etc., and achieve simple structure, reduction of production materials, and reduction of production and transportation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention can directly weld the two side wings and the two vertical sides of the connecting unit to the upper beam and the corner post respectively through the provided connecting unit, and the structure is simple. The first flank and the second flank are required for welding, which reduces manufacturing materials and lowers manufacturing and transportation costs. The present invention will be described in detail below in conjunction with specific implementation methods and accompanying drawings.

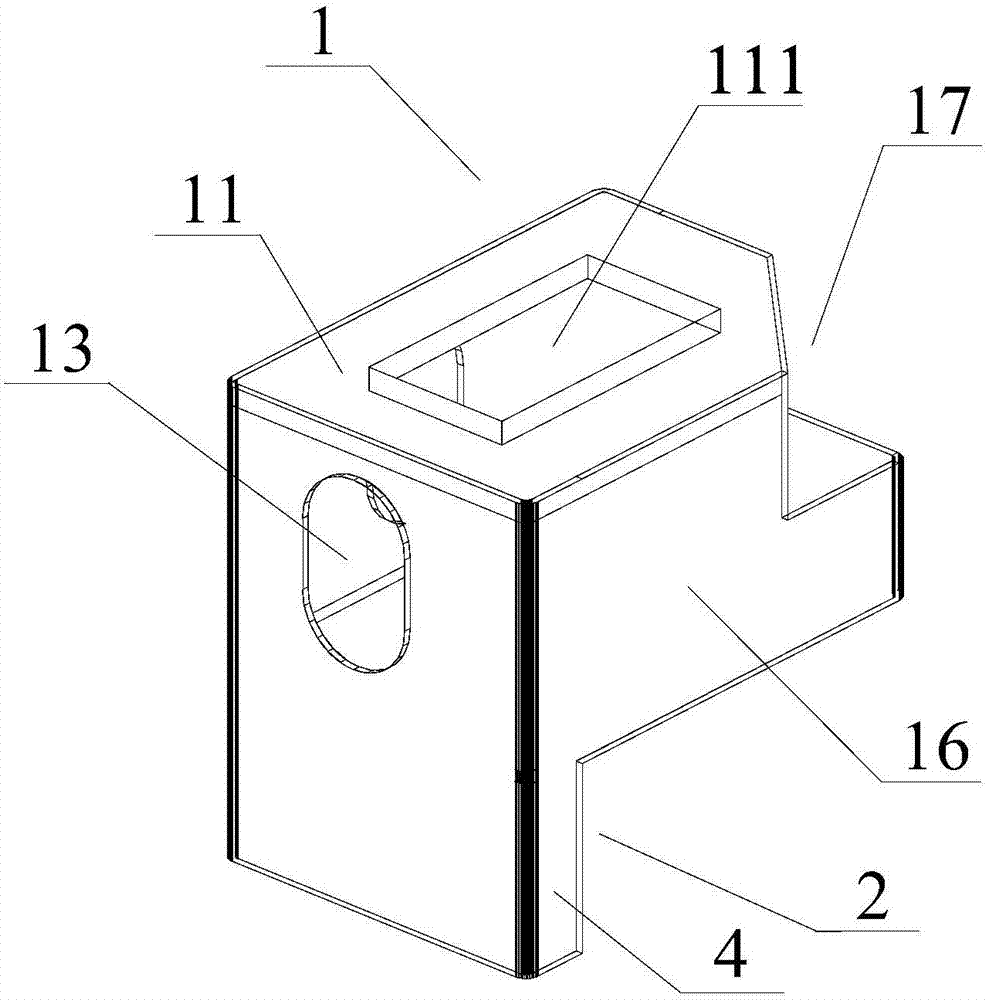

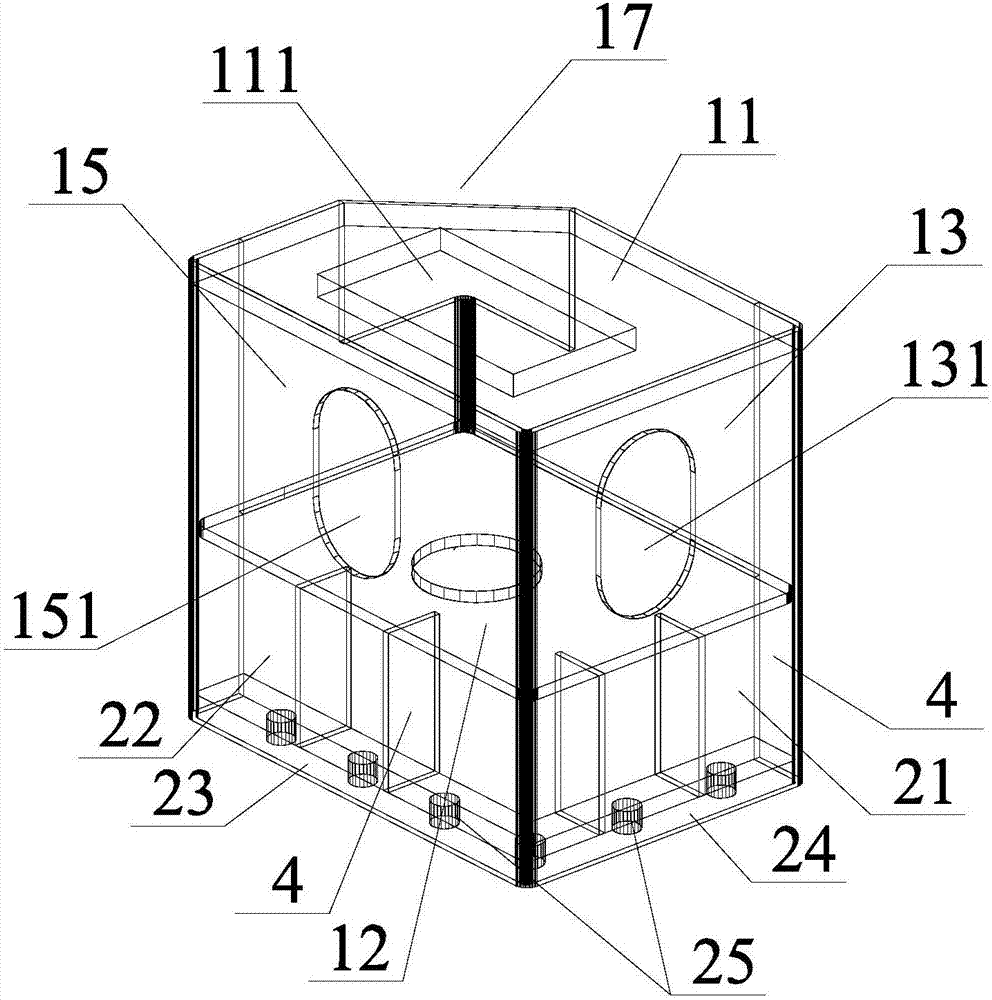

[0028] Such as Figure 1-4 As shown, the present invention provides a corner piece, including: a hoisting unit 1 for hoisting with a cavity in the middle; a connecting unit 2 for fixed connection with the upper beam and the corner post;

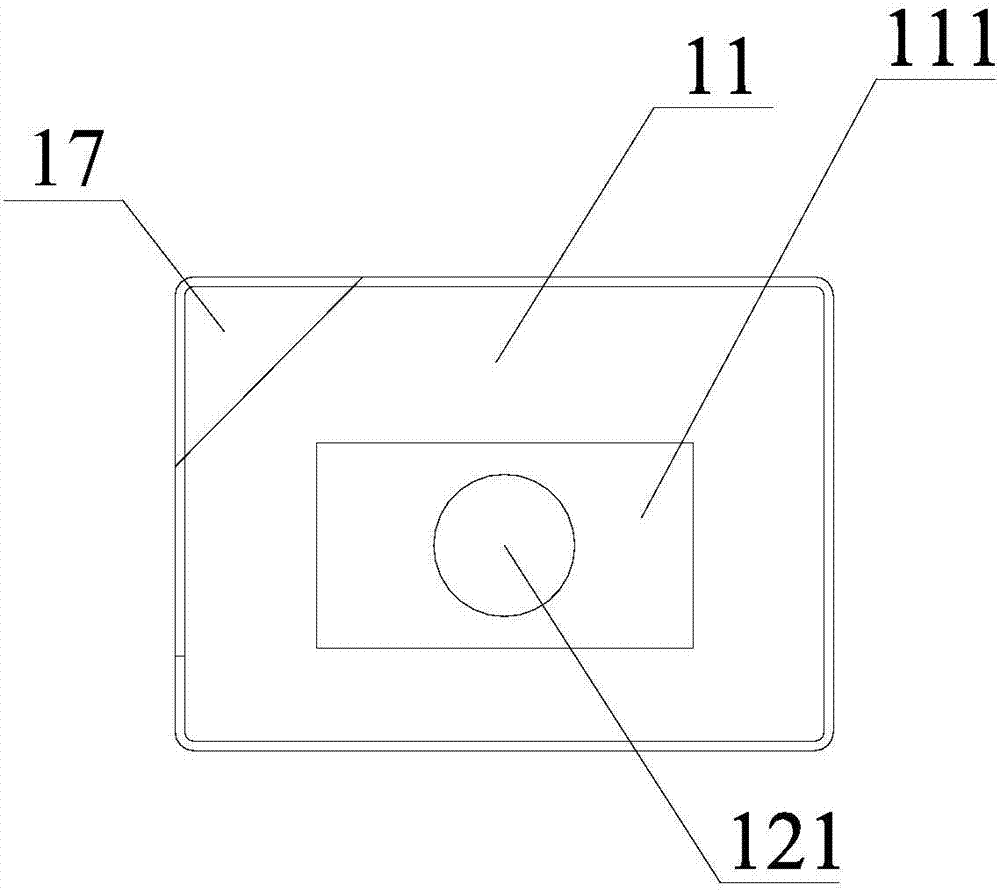

[0029] The hoisting unit 1 can be set in the shape of a cuboid or a cube according to requirements. This embodiment takes a cuboid as an example for illustration; the hoisting unit 1 includes a top surface 11, a bottom surface 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap