Rotation garage

A garage and rotary lever technology, applied in the field of bicycle garages, can solve problems such as bicycle damage to the upper parking structure, and achieve the effects of high space utilization, guaranteed stability and safety, and convenient car pickup.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

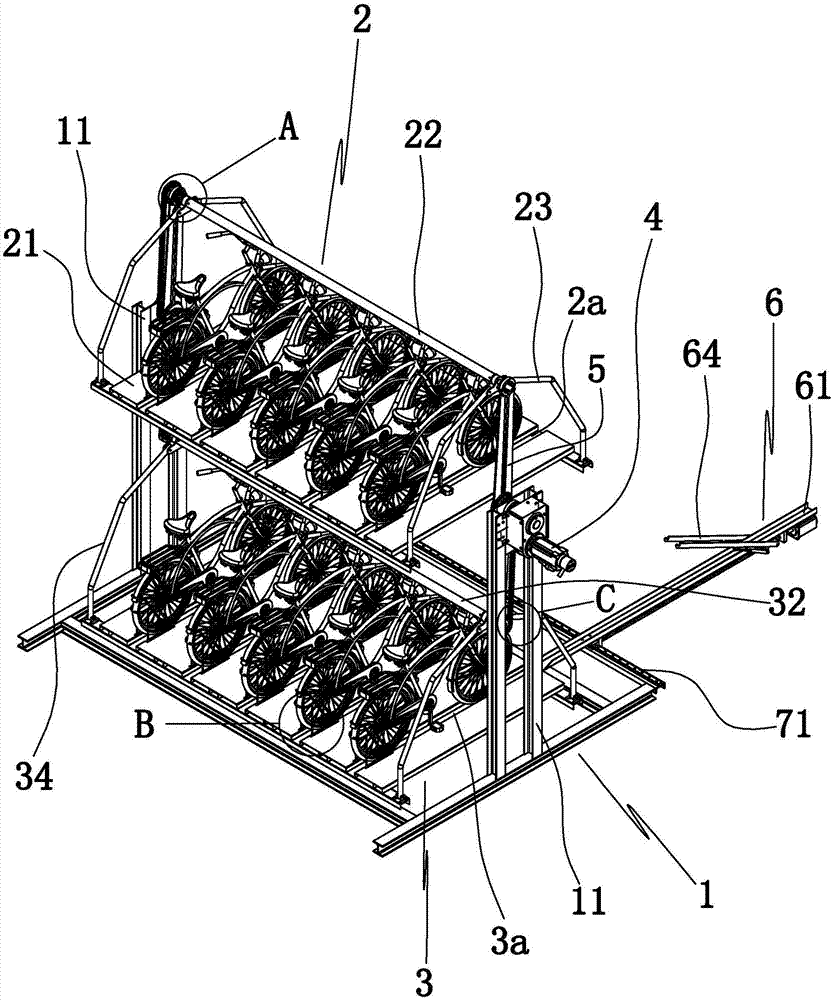

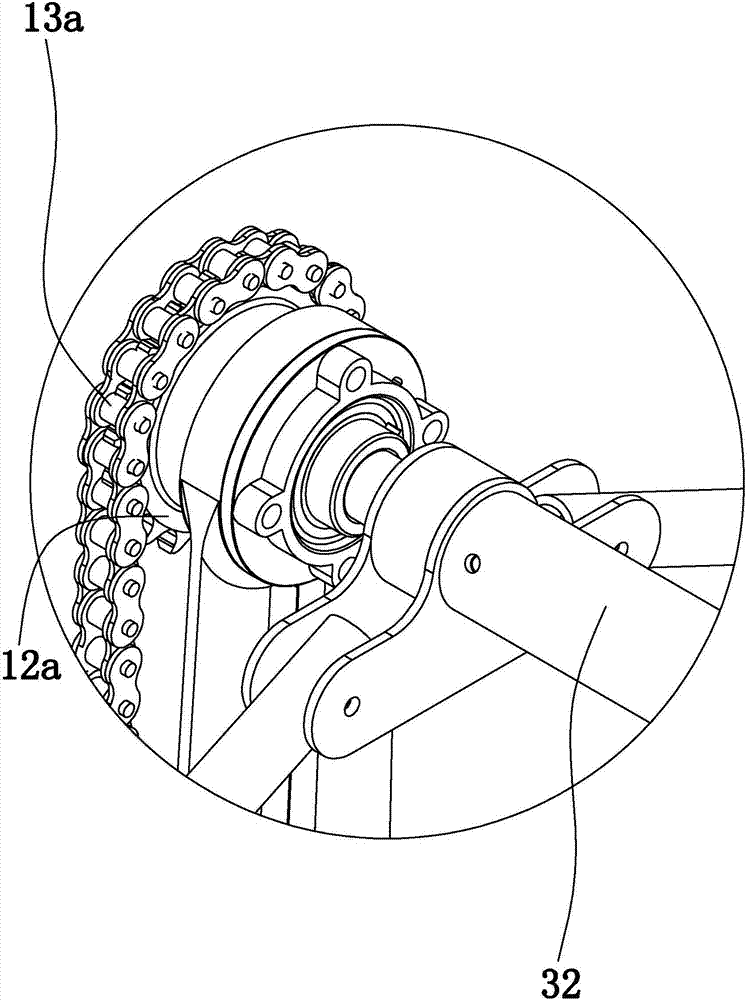

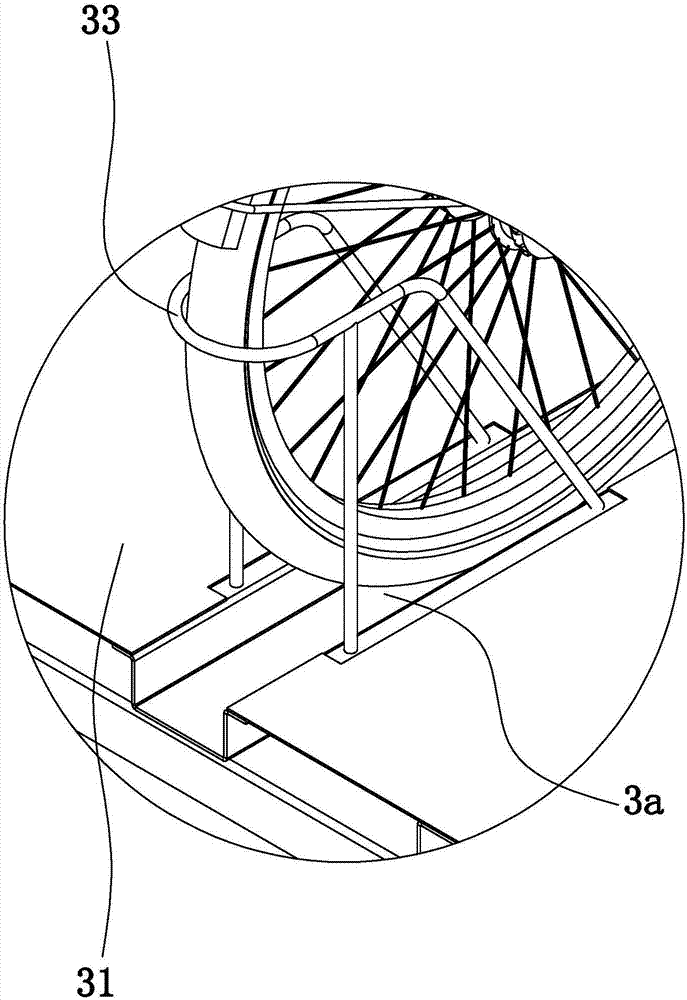

[0023] Such as Figure 1 to Figure 7 As shown in , a rotary garage includes a main frame 1, an upper frame 2, a lower frame 3, a rotary structure and a servo motor 4, and the upper frame includes an upper parking plate 21, an upper top shaft 22 and several The upper truck frame on the upper parking plate, the upper jacking shaft is fixed with the upper platform through the upper link frame 23, and the lower platform includes the lower parking plate 31, the lower jacking shaft 32 and some lower truck frames arranged on the lower parking plate 33. The lower jacking shaft is fixed to the lower frame through the lower link frame 34. The rotary structure includes two symmetrically arranged rotary rods 5. The upper frame and the lower frame are both located between the two rotary rods. One end of the rotary rod is set There is an upper bearing 51 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com