Recovery device of deep water submarine pipeline

A submarine pipeline and recovery device technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as tearing of submarine pipeline pins, and achieve the effect of reducing risks and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

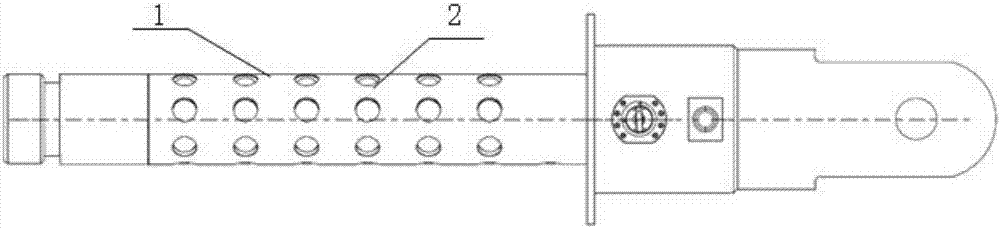

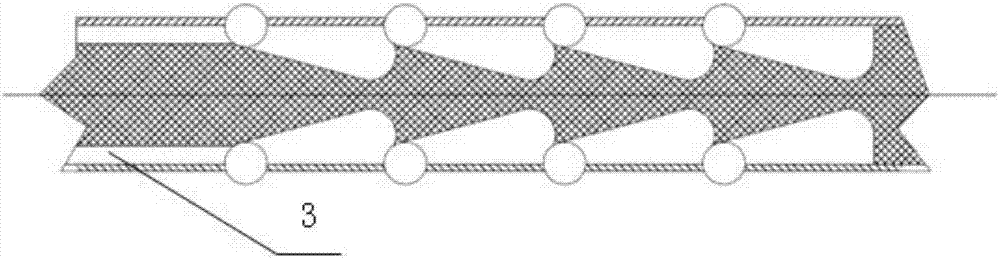

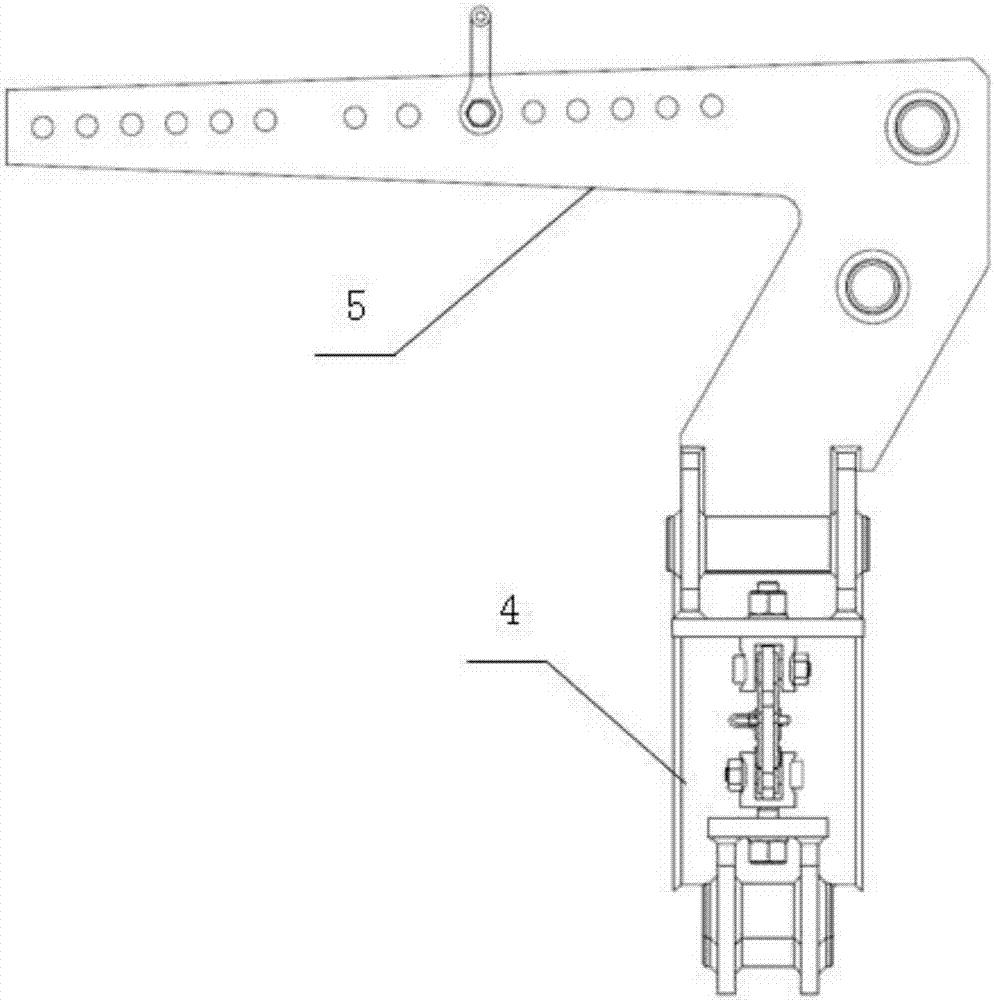

[0021] like figure 1 — Figure 6 As shown, the present invention includes: a shaft sleeve 3, an excitation device 6 connected to one end of the shaft sleeve 3 by bolt connection, a quick release mechanism 4 mounted on the excitation device 6 in a clamping manner, and a quick release mechanism 6 mounted on the shaft sleeve 3. The mechanical arm 5; wherein, the bushing 3 includes: a bushing shell 1, several bushing holes arranged on the bushing shell 1, load-bearing steel balls 2 set in the bushing holes, through the shaft bushing 3 Shrink or stretch, so that the load-bearing steel ball 2 is hidden in the bushing hole or contacts with the inner wall of the submarine pipeline 8 through the bushing hole.

[0022] The inside of the above-mentioned shaft sleeve 3 is wedge-shaped, the head of the shaft sleeve 3 is equipped with a seal, and the tail of the shaft sleeve 3 is made into a U-shaped hook for connecting the snap ring and the sling 9 .

[0023] like Figure 7 As shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com