High-energy pipeline whipping limiting system and method

A technology of high-energy pipelines and restricting devices, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., and can solve the problems of low resistance of high-energy pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

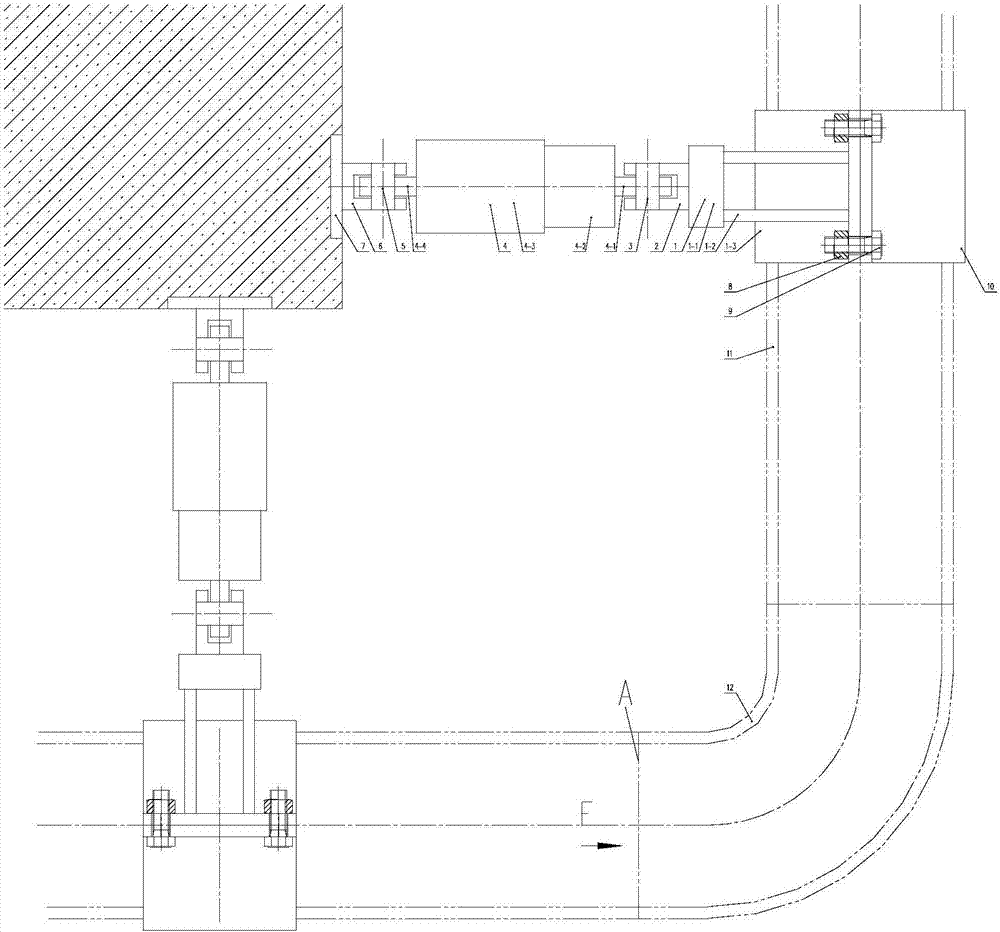

[0012] Such as figure 1 As shown, a high-energy pipeline slam limiting system includes several groups of slam limiting devices, two of which are respectively installed on both sides of the high-energy pipeline elbow 12, and the sling limiting devices include brackets Component 1, first pin seat 2, first pin shaft 3, speed-sensitive hydraulic damper 4, second pin shaft 5, second pin seat 6, nut 8, bolt 9, plate type arc pipe collar 10; Bracket assembly 1 comprises bracket bottom plate 1-1, bracket vertical plate 1-2, arc-shaped supporting plate 1-3, the right end of bracket vertical plate 1-2 is welded with bracket bottom plate 1-1, bracket vertical The left end of the plate 1-2 is welded to the arc-shaped supporting plate 1-3, and the bracket bottom plate 1-1, the bracket vertical plate 1-2, and the arc-shaped supporting plate 1-3 are welded to each other to form a bracket assembly 1; the speed Sensitive hydraulic damper 4 includes damper moving part pin head 4-1, damper movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com