Method for preparing aluminium electrolytic capacitor

An aluminum electrolytic capacitor and capacitor core technology, applied in the field of capacitors, can solve the problems of time-consuming and laborious, inability to grasp the impregnation progress in real time, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

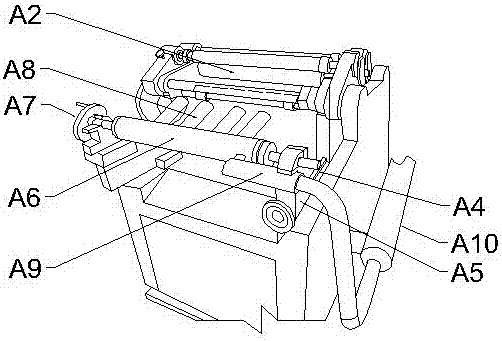

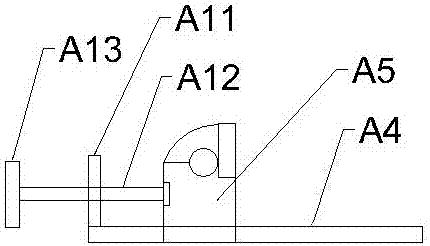

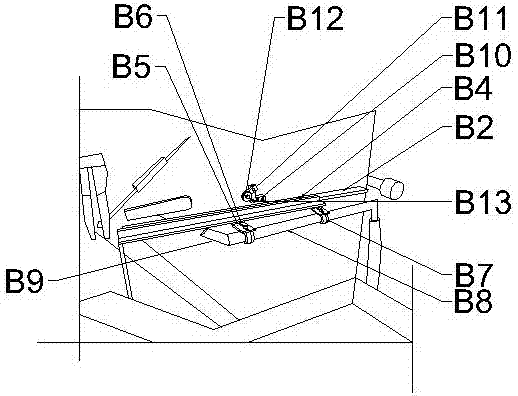

[0024] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach Figure 7 , the preparation method described in this embodiment includes the following steps: cutting-printing-nailing-winding-impregnation-assembly-washing-casing-aging-sorting-cutting-labeling-packaging-into library; among them,

[0025] Cutting, cutting by a cutting machine, the dust generated by cutting is absorbed by the cutting suction mechanism, and sent to the circulating dust reduction mechanism through the dust suction main pipe to settle the dust; the dust suction roller in the cutting suction mechanism can be adjusted according to the The paper cutting position rotates the overall angle of the suction port. At the same time, the screen at the suction port can block the entry of large pieces of core paper. The sliding seat in the cutting suction mechanism can adjust the fron...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap