High-voltage solid-closed type cable intermediate joint

A technology for cable intermediate joints and intermediate joints, applied in the direction of cable joints, etc., can solve the problems of hidden safety hazards and poor sealing performance of power cables, and achieve the effect of ensuring fireproof and explosion-proof effect, good fireproof performance and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

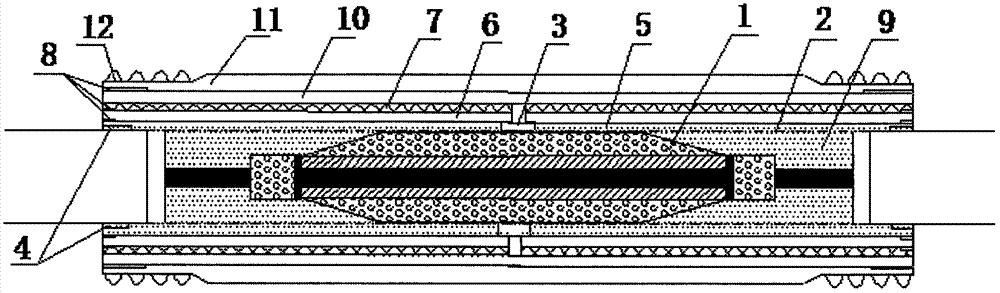

[0017] Such as figure 1 As shown, a high-voltage solid-sealed cable intermediate joint includes an intermediate joint main body 1, and a nano-cage bone mesh 2 is provided on the outer surface of the intermediate joint main body 1, and the nano-cage bone mesh 2 is fixed by a cable tie. The three-port glue filling valve 3, the two ends of the nano-cage mesh 2 are respectively provided with two exhaust pipes 4 horizontally, the nano-cage mesh 2 is wrapped with an anti-static film 5, and the anti-static film 5 is wrapped with a PVC tape 6, The PVC tape 6 is sealed with waterproof tape 7, and the sealant 8 is used to seal the antistatic film 5 and the ports on both sides of the PVC tape 6, and the sealant 8 is also used to seal the ports on both sides of the PVC tape 6 and the waterproof tape 7. seal.

[0018] The antistatic film 5, the PVC tape 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com