Energy-saving type rubber fender sand blasting machine

A technology of rubber fenders and sandblasting machines, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc. It can solve the problems of human injury, sand material loss, and large sandblasting room occupation, so as to save resources , to avoid the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

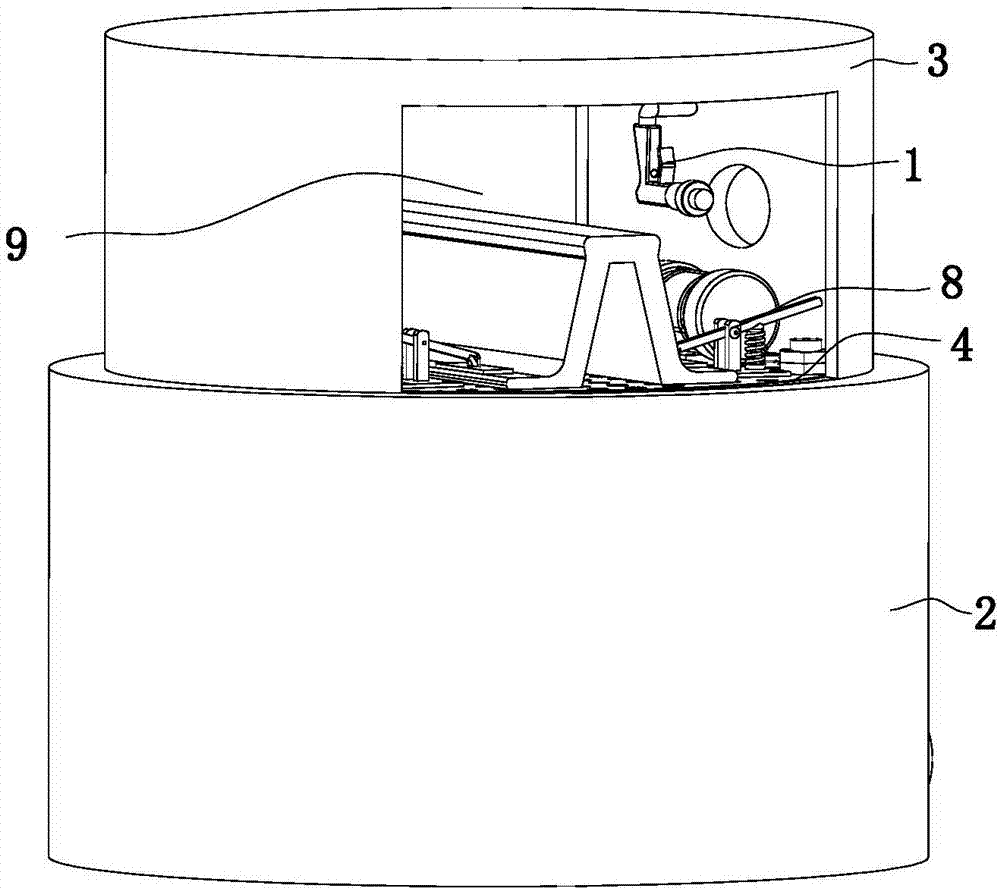

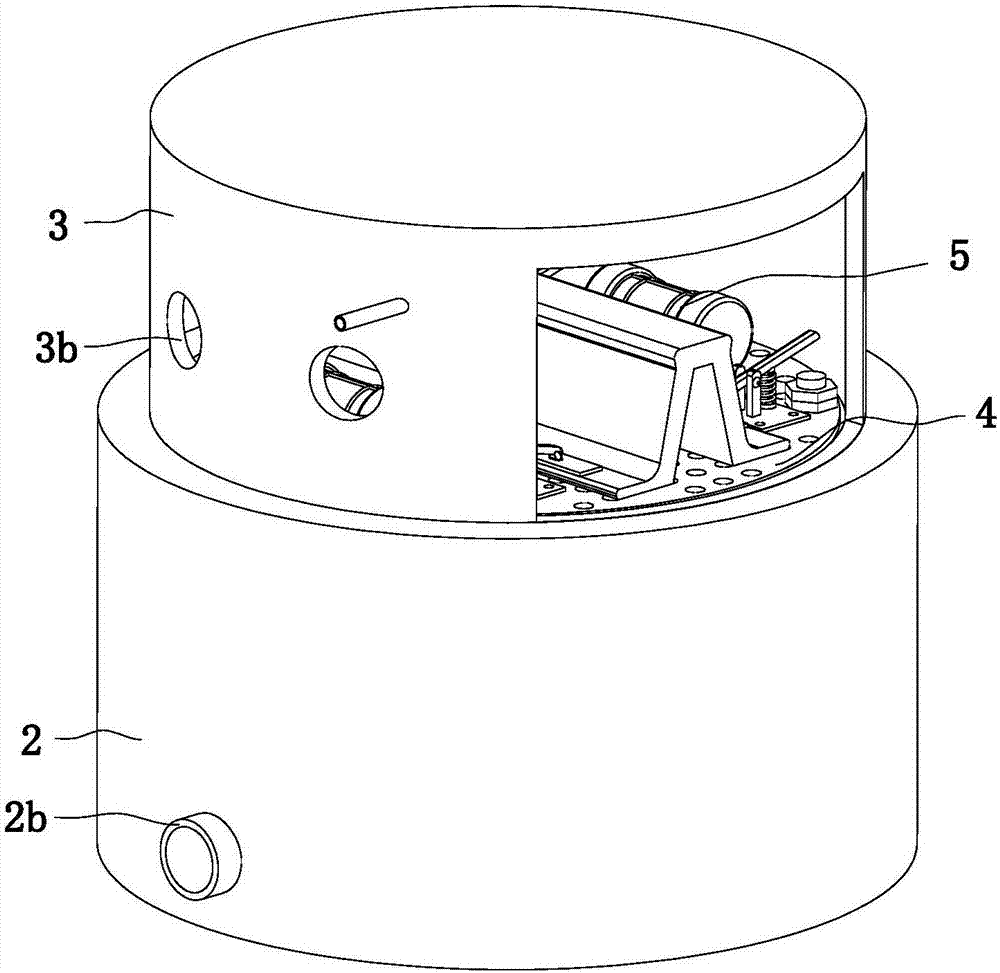

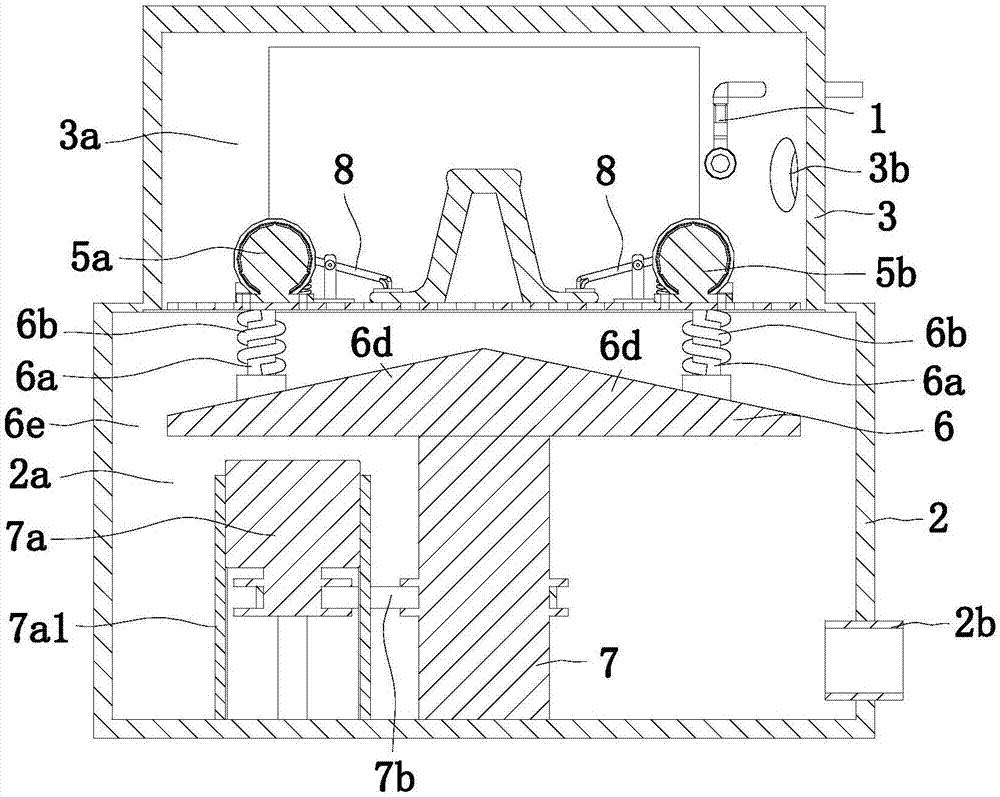

[0040] The second specific embodiment of the present invention: an energy-saving rubber fender sandblasting machine, including a sandblasting machine body and a spray gun 1, a lower casing 2 is provided on the side of the sandblasting machine body, and the lower casing 2 is fixedly installed with an upper casing 3, the upper casing 3 is provided with a sandblasting chamber 3a, and the lower casing 2 is provided with a sand collection chamber 2a, the sandblasting chamber 3a and the sand collection chamber 2a A storage board 4 is arranged between them, and the storage board 4 is fixedly connected with the lower casing 2. A plurality of sand passage holes 4a are provided on the storage board 4. A vibration motor 5 is installed on the upper end surface of the storage board 4. The upper housing The side wall of the body 3 is provided with a plurality of pairs of hand holes 3b, the spray gun 1 is hung on the inner wall of the upper shell 3, the spray gun 1 communicates with the sandb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com