Control device of transformer substation hot-line work robot

A technology of live operation and control device, applied in the field of power system, can solve the problems of equipment grounding fault, reduce the safety of robot operation, etc., and achieve the effect of improving stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

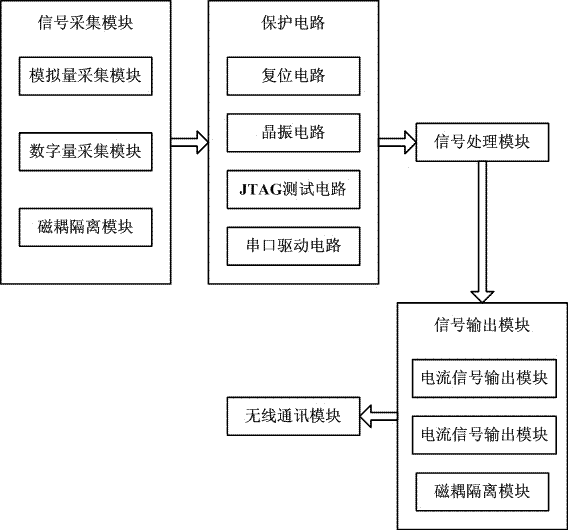

[0038] Please refer to figure 1 As shown, the embodiment of the present invention provides a control device for a live working robot in a substation, including:

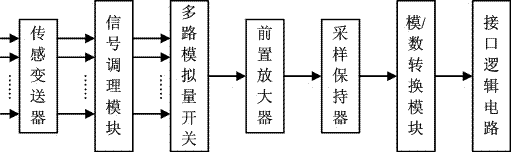

[0039] The signal acquisition module is used to obtain the walking status signal and working status signal of the live working robot in the substation through the wireless network;

[0040] The signal processing module is used to process the robot walking state signal and the working state signal obtained by the signal acquisition module, use the processing result as a comparison basis for control, and send a movement command of the mechanical arm to drive the corresponding proportional valve to complete the movement of the mechanical arm action;

[0041] The signal output module is used to receive and display the robot's walking state an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com