Plate rolling heat exchange body, heat exchanger of modularly-assembled plate rolling heat exchange body and heat exchange method

A technology of heat exchangers and heat exchangers, applied to indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problems of high processing and manufacturing costs, complex overall structure, and enhanced practicability, and achieve manufacturing Low cost, improved heat transfer efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

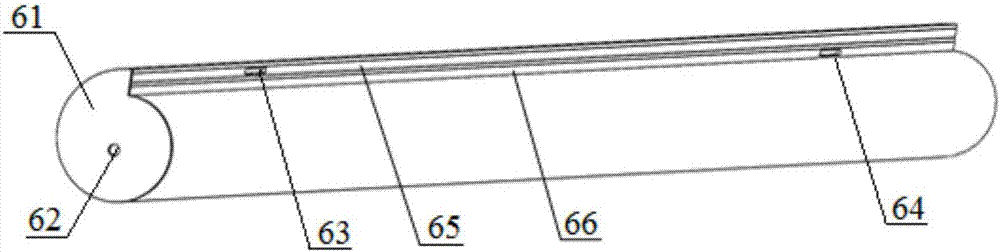

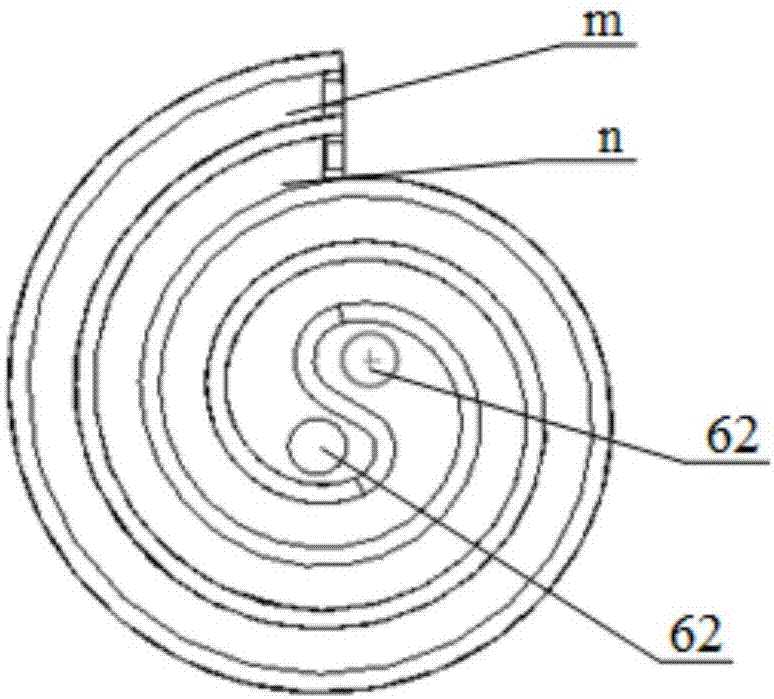

[0033] combine figure 2 and image 3 , a coiled plate heat exchange body in this embodiment, including a tube seal 61, a first horizontal plate 65, a second horizontal plate 66 and a flat plate, the coiled plate heat exchange body 6 is folded in half by a flat plate and the rear edge It is rolled in the same direction, and ring tracks m and n are formed inside the rolled tubular body. Pipe seals 61 are arranged on both sides of the tubular body, and a through hole 62 is opened on the pipe seal 61. One side of the through hole 62 communicates with the circular track m, and the other side of the through hole 62 communicates with the circular track n. The upper and lower outlets of the tubular main body along the axial direction The places are respectively closed by a first horizontal plate 65 and a second horizontal plate 66, the first horizontal plate 65 is provided with a first horizontal plate through hole 63, and the second horizontal plate 66 is provided with a second hor...

Embodiment 2

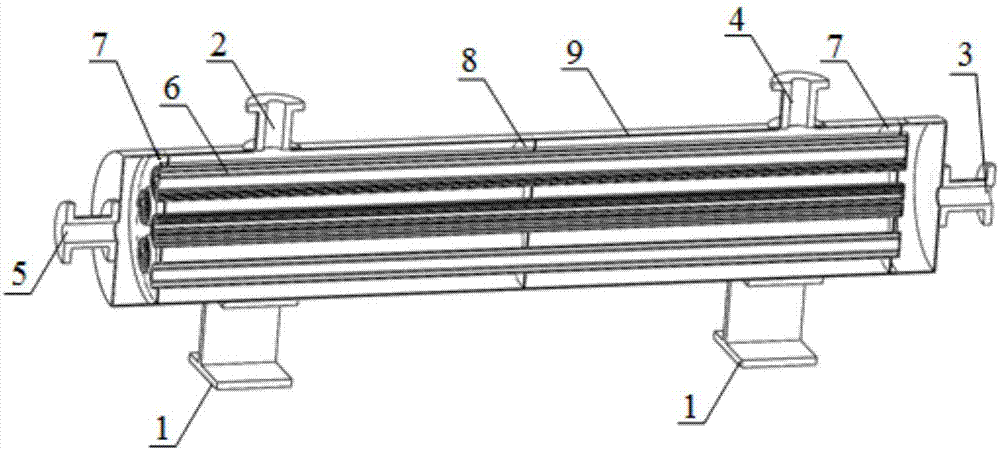

[0035] combine figure 1 , a heat exchanger of a modularly assembled coiled plate heat exchanger in this embodiment, including a support 1, a flow medium a inlet 2, a flow medium a outlet 3, a flow medium b inlet 4, a flow medium b outlet 5, such as The coiled plate heat exchanger 6 , the tube sheet 7 , the middle partition plate 8 and the heat exchanger shell 9 described in Embodiment 1. The heat exchanger of this embodiment is a horizontal heat exchanger, and the bottom of the heat exchanger shell 9 is symmetrically provided with two supports 1, and the horizontal heat exchanger is supported by the supports 1, and the middle partition 8 is set Inside the heat exchanger housing 9, see Figure 4, the intermediate partition 8 is provided with a plurality of mounting holes 81 that conform to the shape of the coiled plate heat exchange body 6, and the coiled plate heat exchange body 6 is inserted into the mounting holes 81, and through the tube plates 7 arranged symmetrically on ...

Embodiment 3

[0041] A coiled plate heat exchange body, a heat exchanger for modularly assembling a coiled plate heat exchange body, and a heat exchange method in this embodiment are basically the same as in Embodiment 2, except that the coiled plate heat exchange body in this embodiment The arrangement of 6 on the intermediate partition 8 is a corner triangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com