Scraping and conveying mechanism

A conveying mechanism and scraping technology, applied in conveyors, transportation and packaging, containers, etc., can solve the problems of unsmooth conveying of materials, time-consuming and labor-intensive, affecting service life, etc., to ensure smooth conveying and avoid dirt. The effect of accumulating and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

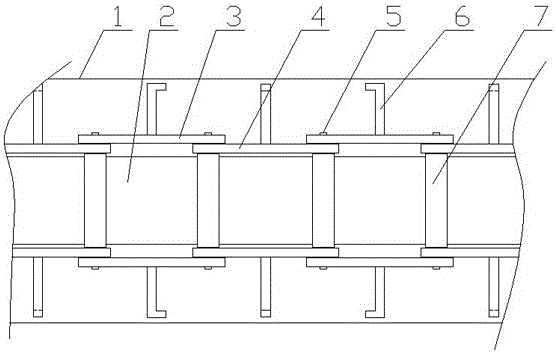

[0013] The specific implementation, structure, features and functions of the scraping and conveying mechanism proposed according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0014] see figure 1 , the scraper conveying mechanism of the present invention comprises connecting plate A3, connecting plate B4, and scraper 6, wherein: connecting plate A3 and connecting plate B4 are interleavedly detachably connected, and connecting plate B4 two ends are equipped with roller 7, and roller 7 is placed on the top of the slideway 2, and both sides of the connecting plate A3 and the connecting plate B4 are equipped with scrapers 6, and the scrapers 6 are located in the material box 1. Connecting plate A3 and connecting plate B4 are connected by the revolving pin 5 at two ends, and cylinder 7 is contained on the revolving pin 5. The scrapers 6 are evenly distributed in the middle of the connection plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com