Automatic cutting and forming device

A forming device and automatic technology, applied in the field of wire rod processing, can solve the problems of wire rod complex shape and low production cost, and achieve the effects of strong versatility, low production cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

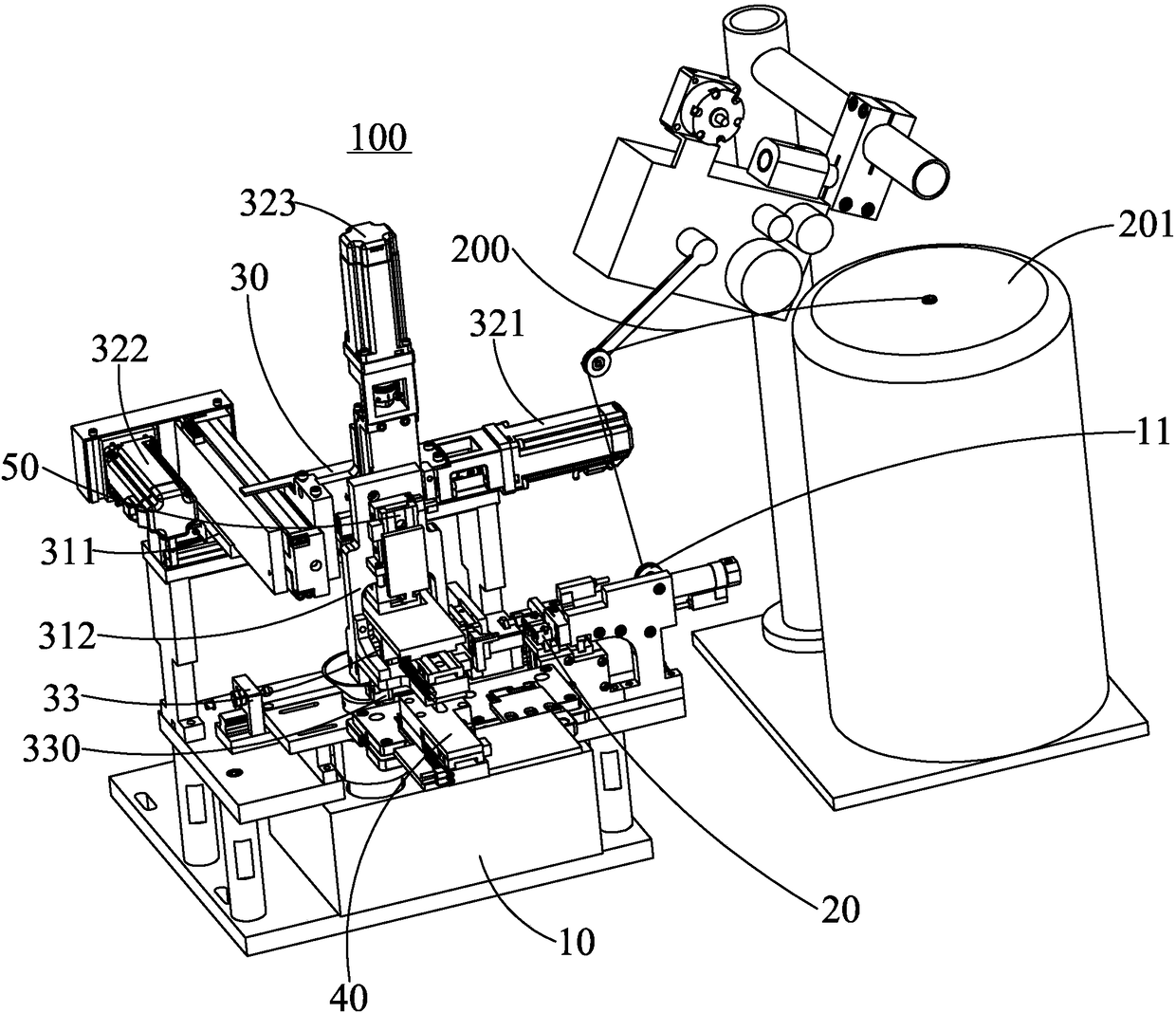

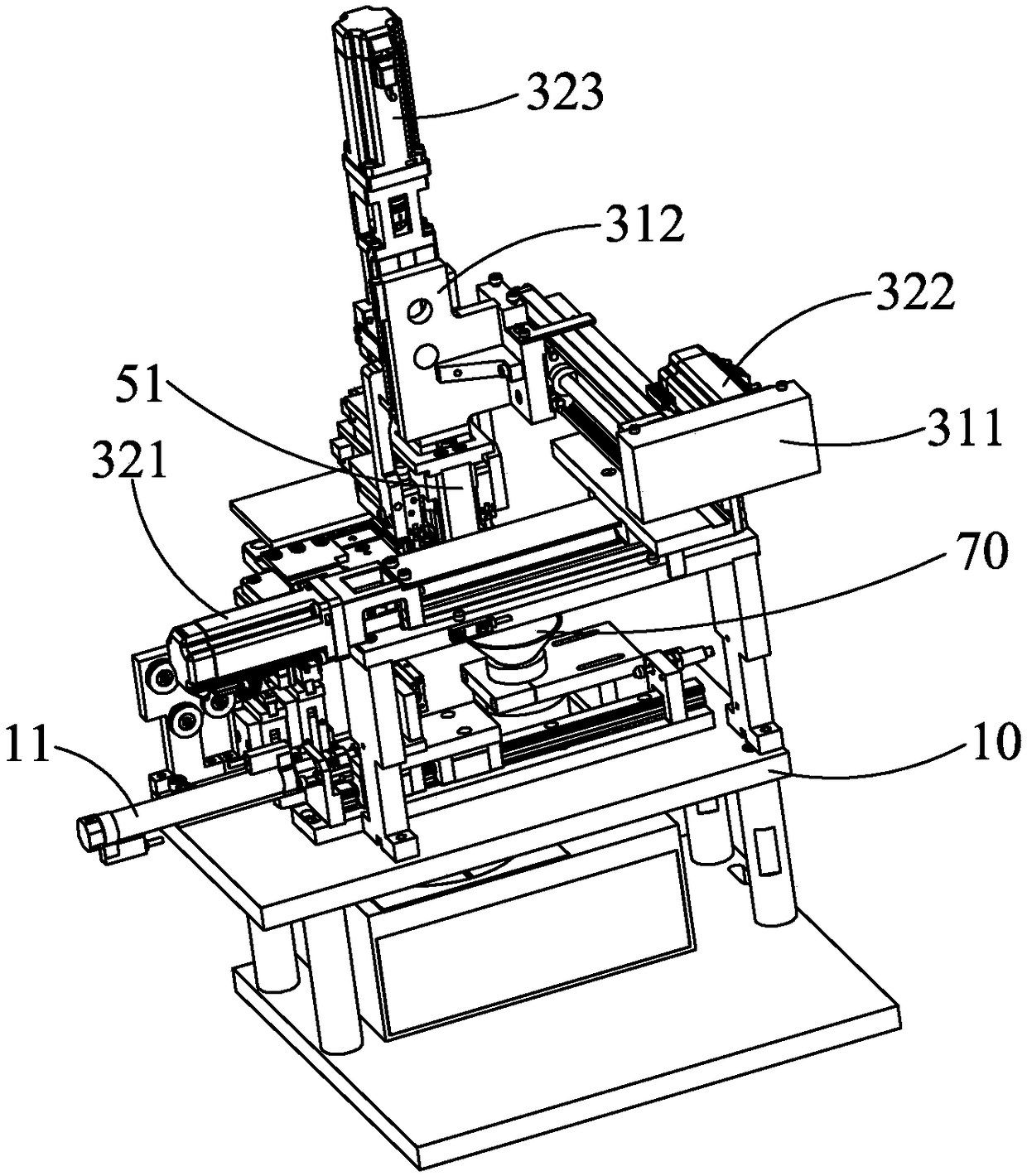

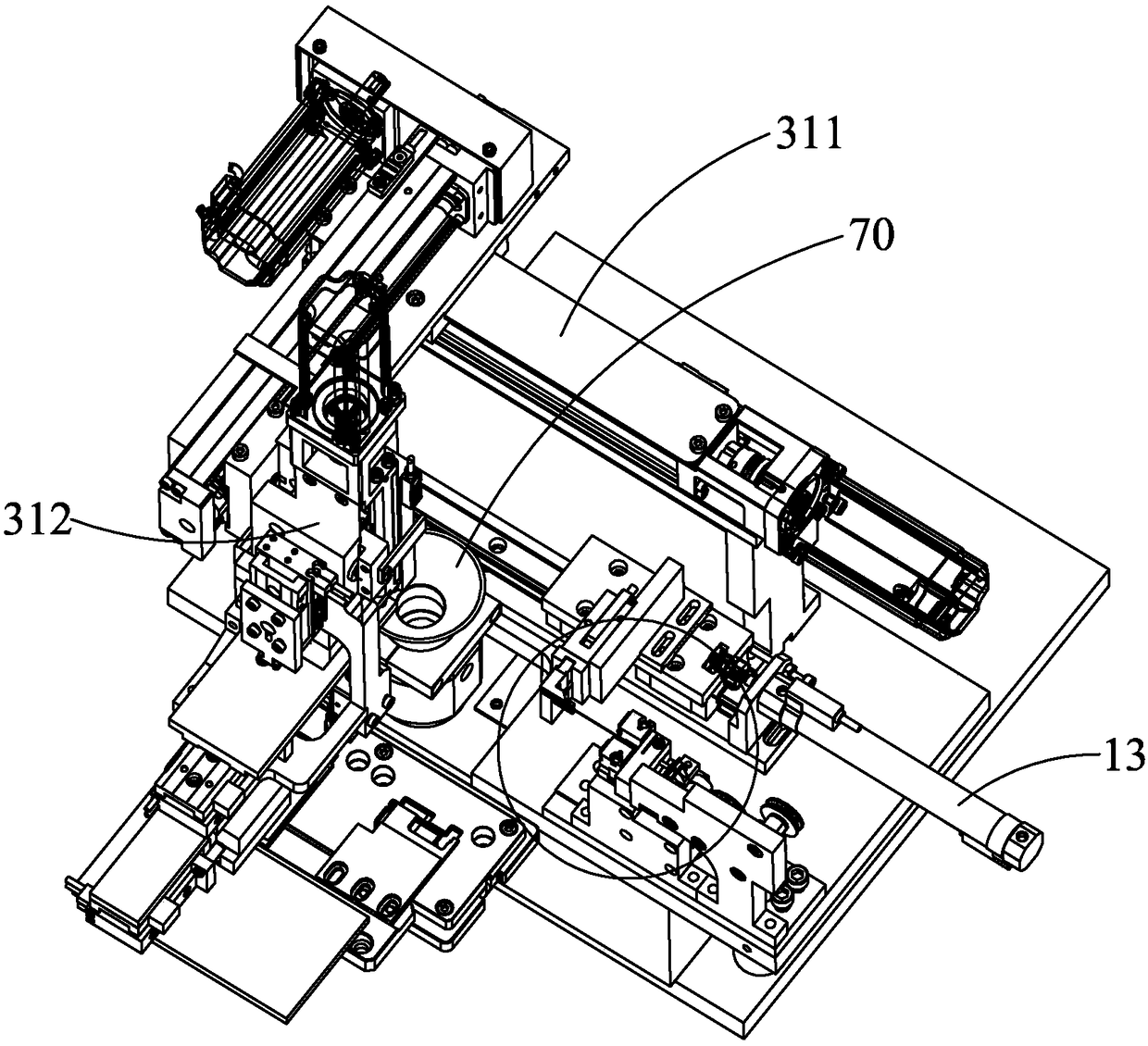

[0016] see Figure 1 to Figure 10 As shown, the automatic cutting and forming device 100 of the present invention includes a frame 10, a cutting mechanism 20, a feeding mechanism 30, a forming mechanism 40, a punching mechanism 50, a carrier 60 and a waste box 70, and the carrier 60 and the waste box 70 is fixed on the frame 10.

[0017] The frame 10 is provided with a reel 11, a wire conduit 12 and a pen-shaped cylinder 13, and the wire barrel 201 for storing the wire 200 is placed on the underside of the reel 11, and the wire 200 enters the cutting mechanism 20 through the reel 11, and the wire The tube 12 extends horizontally along the front-to-back direction for the wire 200 to pass through.

[0018] The cutting mechanism 20 includes the first and second finger cylinders 21 and 22 spaced apart front and rear, and the cutting cylinder 23 between the first and second finger cylinders 21 and 22. The first finger cylinder 21 is connected with a With the closed first jaw 210,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com