High-precision slight-adjustment fine boring tool

A high-precision, fine-boring technology, applied in the direction of tool holders, etc., can solve the problems of affecting the accuracy of processing, prone to vibration, and expensive processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

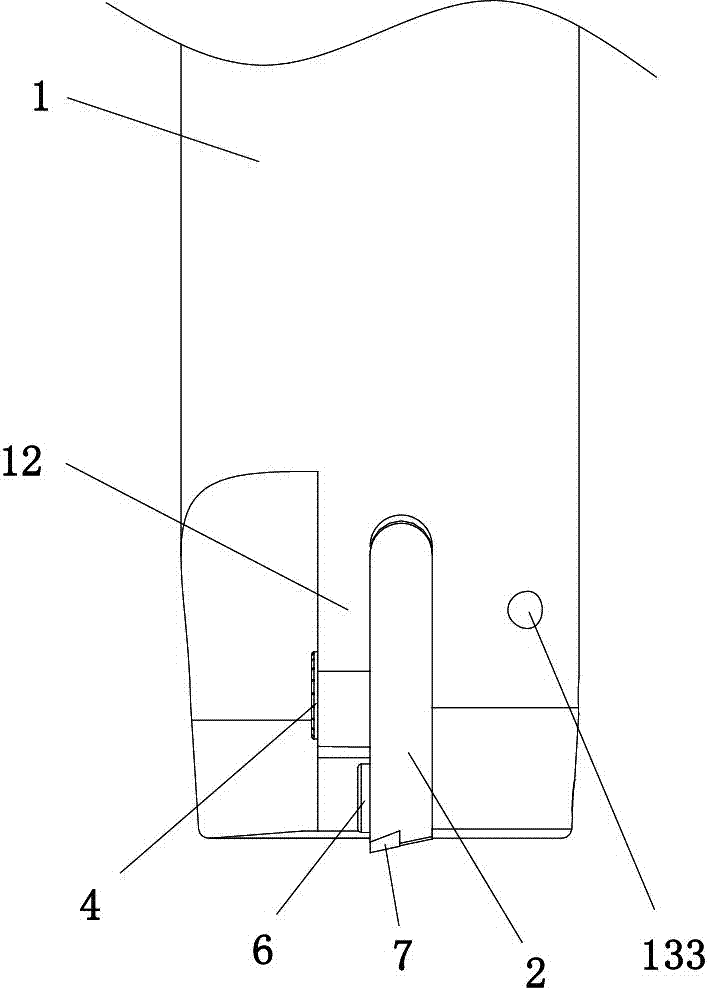

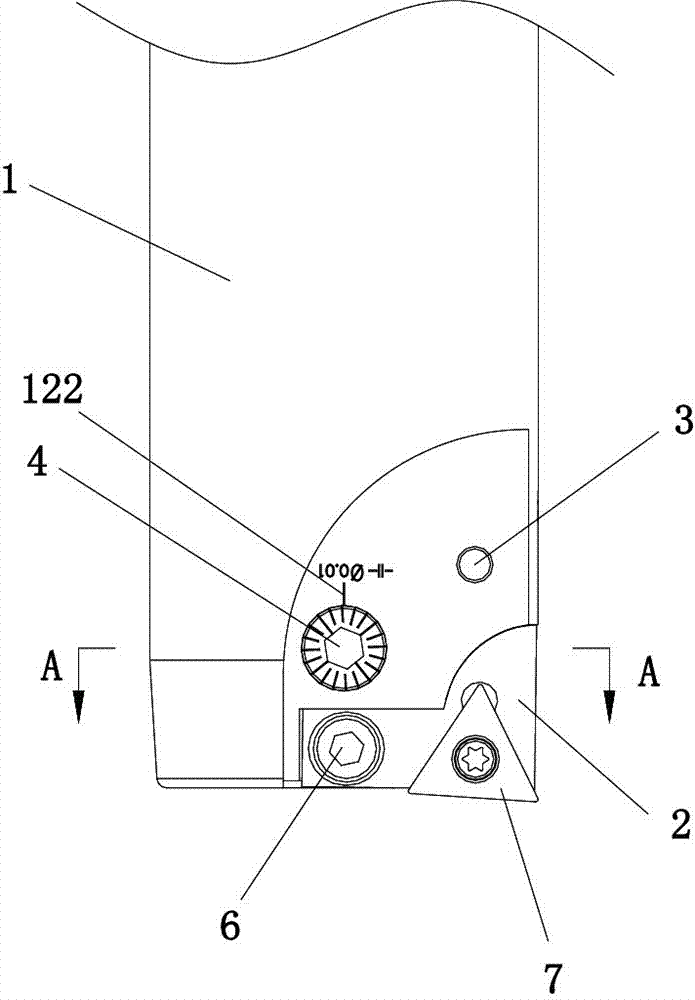

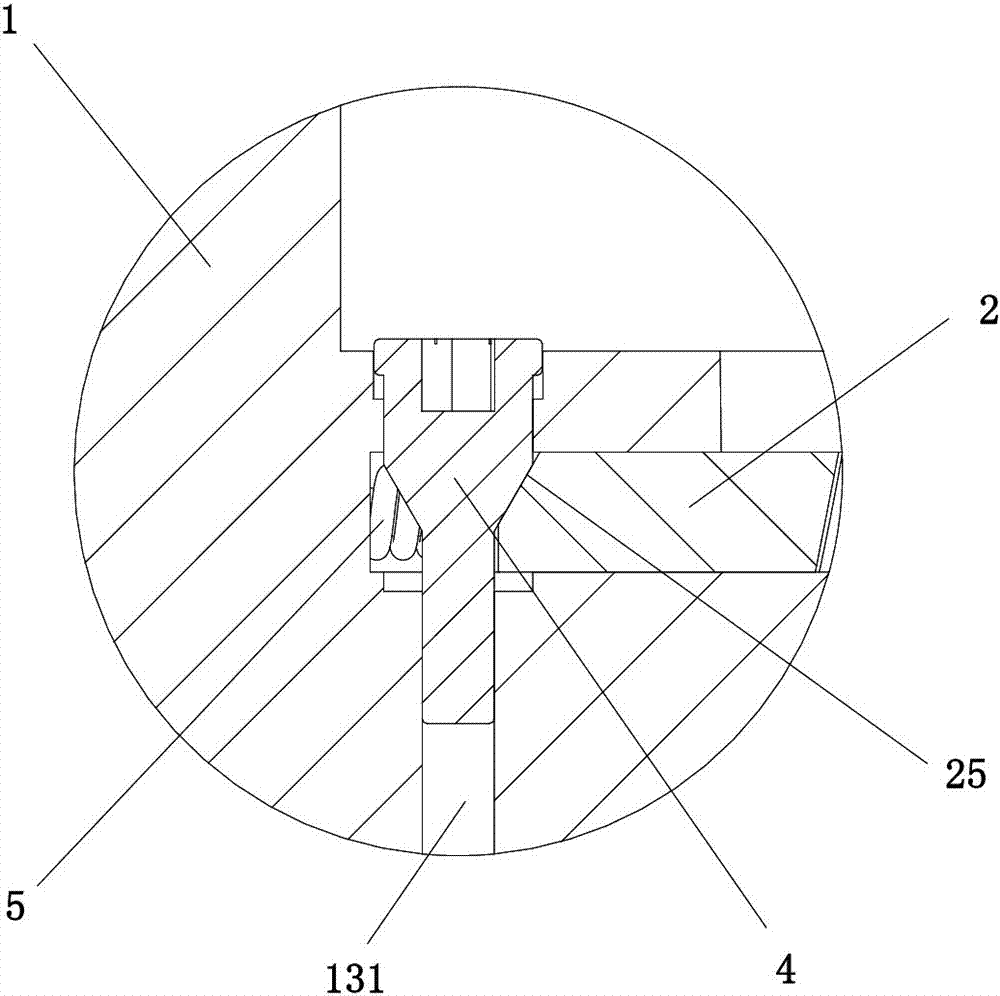

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: Figure 1 to Figure 5 As shown, a high-precision fine-tuning fine boring tool includes a tool bar 1 and a blade seat 2. The guide bar 1 is provided with a mounting part 13, and the mounting part 13 is provided with a fine-tuning screw hole 131 and a fastening screw. hole 132, the blade seat 2 is connected and installed on the installation part 13 by a pin 3, a locking hole 22 is arranged on the blade seat 2, and a locking bolt 6 is arranged in the locking hole 22 and the lock The stop bolt 6 is screwed into the fastening screw hole 132 so as to fasten and lock the blade seat 2 on the installation part 13, and the fine-tuning screw hole 131 is provided with a fine-tuning bolt 4, and the fine-tuning bolt 4 is provided with The fine-tuning conical surface 42, the blade seat 2 is provided with a fine-tuning pressure-bearing inclined surface 25, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com