Liquid ejection head and liquid ejection apparatus

A liquid ejection head, liquid technology, applied in printing and other directions, can solve the problem of difficult to increase the width of the flow path, and achieve the effect of suppressing the change of circulation flow and pressure change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

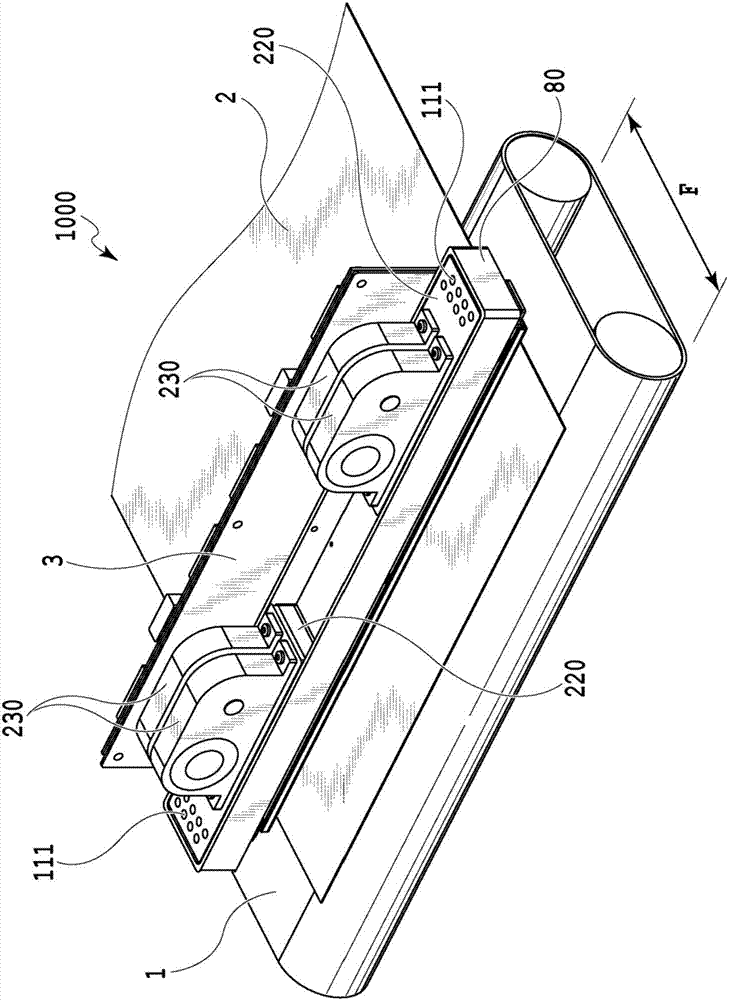

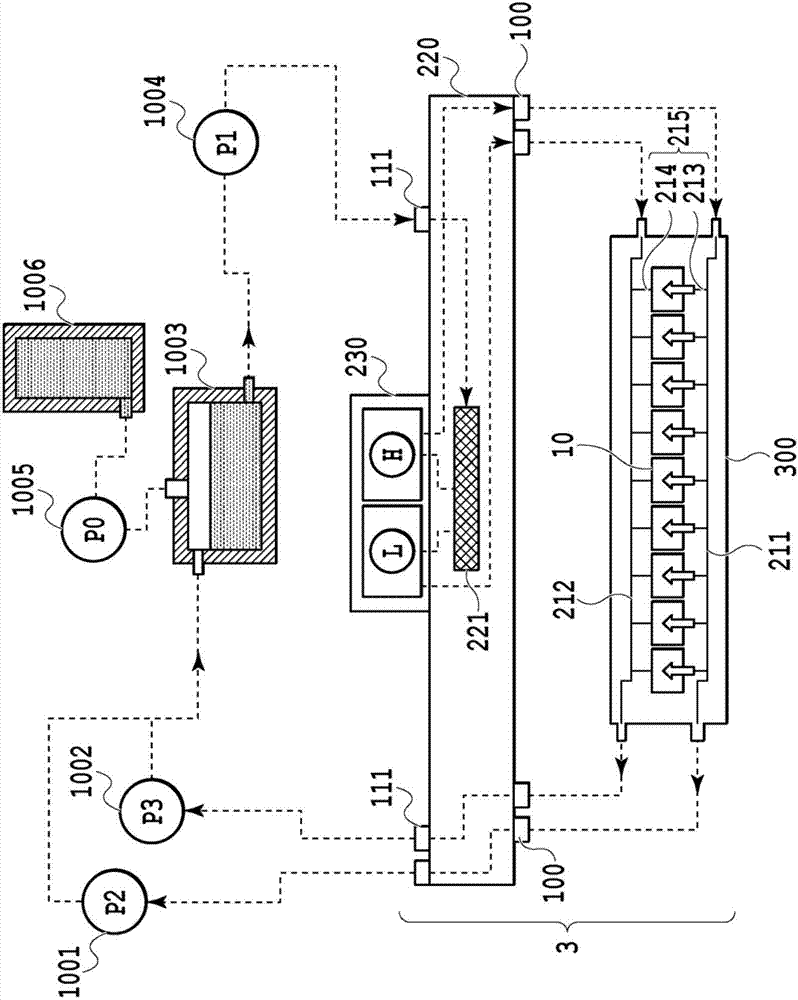

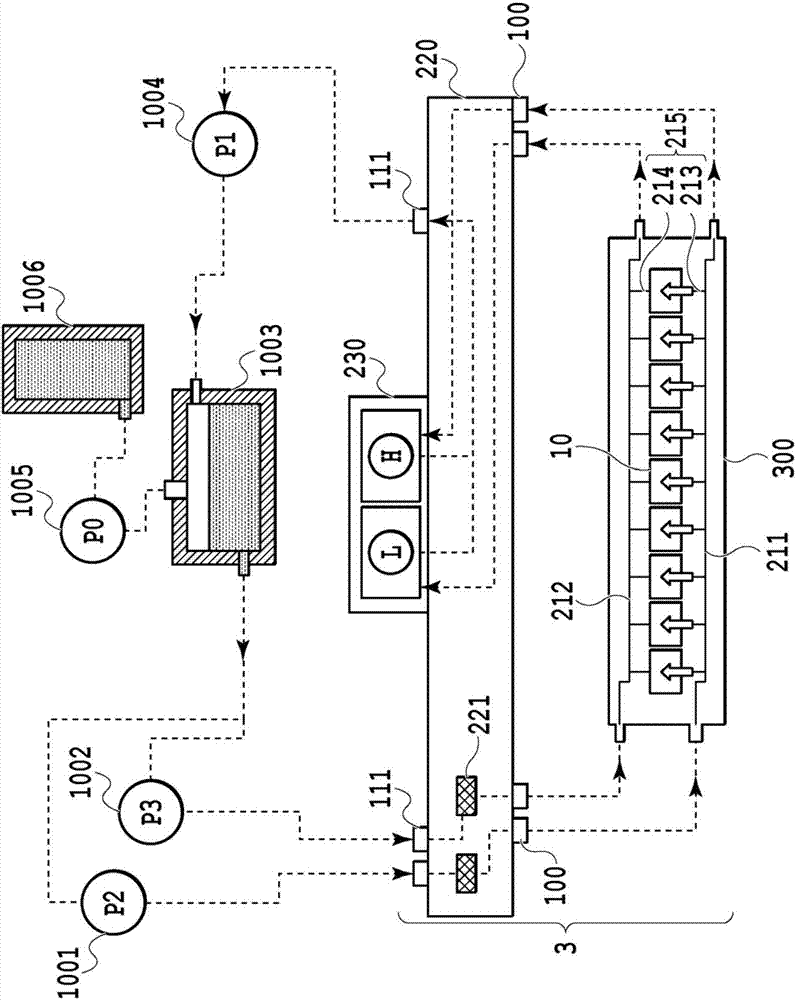

[0188] refer to Figure 22A to Figure 28C , the liquid ejection head according to the first embodiment of the present invention will be described. In addition, the liquid supply path of the above-mentioned application example corresponds to the first common supply flow path of this embodiment. Likewise, the liquid recovery path corresponds to the first common recovery flow path, the first communication port corresponds to the opening, the common supply path corresponds to the third common supply flow path, and the common recovery path corresponds to the third common recovery flow path.

[0189] Figure 22A to Figure 22M is an exploded view showing a liquid ejection head according to an embodiment of the present invention. Figure 22A to Figure 22G It is an exploded perspective view showing constituent parts. Figure 22H to Figure 22M are components shown corresponding to the Figure 22B to Figure 22G exploded top view. Figure 23A to Figure 23G is showing Figure 22A A s...

no. 2 approach

[0276] refer to Figure 29A to Figure 32D , a liquid ejection head according to a second embodiment of the present invention will be described. The same reference numerals will be given to the same constituent elements as those of the above-described embodiment, and descriptions thereof will be omitted.

[0277] Figure 29A to Figure 29M is an exploded view showing a main part of the liquid ejection head according to the embodiment of the present invention. Figure 29A to Figure 29G is an exploded perspective view showing constituent parts, Figure 29H to Figure 29M is an exploded plan view showing constituent parts.

[0278] Figure 30 It is a plan view showing the shape of the printing element substrate of the liquid ejection head according to this embodiment. Figure 31 is a schematic perspective view showing the liquid ejection head and showing the end of the ejection port row. FIG. 32 is a graph showing changes in circulation flow rate in this embodiment. Figure 3...

no. 3 approach

[0306] Figure 33A to Figure 33L is a diagram showing a liquid ejection head according to a third embodiment of the present invention. The same reference numerals will be given to the same constituent elements as those of the above-described embodiment, and descriptions thereof will be omitted. Figure 33A to Figure 33L is an exploded view showing a main part of the liquid ejection head according to the embodiment of the present invention. Figure 33A to Figure 33F is a stereogram. Figure 33G to Figure 33L is a top view.

[0307] In this embodiment, if Figure 33G with Figure 33H As shown, one first common supply channel 5313 communicates with the pressure chambers 3023 arranged at the two discharge port rows 3024 . Likewise, one first common recovery channel 5314 communicates with the pressure chambers 3023 arranged at the two discharge port rows 3024 . That is, if Figure 33G with Figure 33H As shown, a first common supply flow path 5313 or a first common recovery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com