Punching missing prevention detection device for small hole punching of punching die

A detection device and a technology for stamping dies, applied in the field of stamping dies, can solve problems such as misjudgment, unusable mechanical sensors, sensitivity effects of photoelectric sensors, etc., so as to reduce production costs, reduce waste of raw materials, improve production efficiency and product qualification rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more obvious and understandable, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

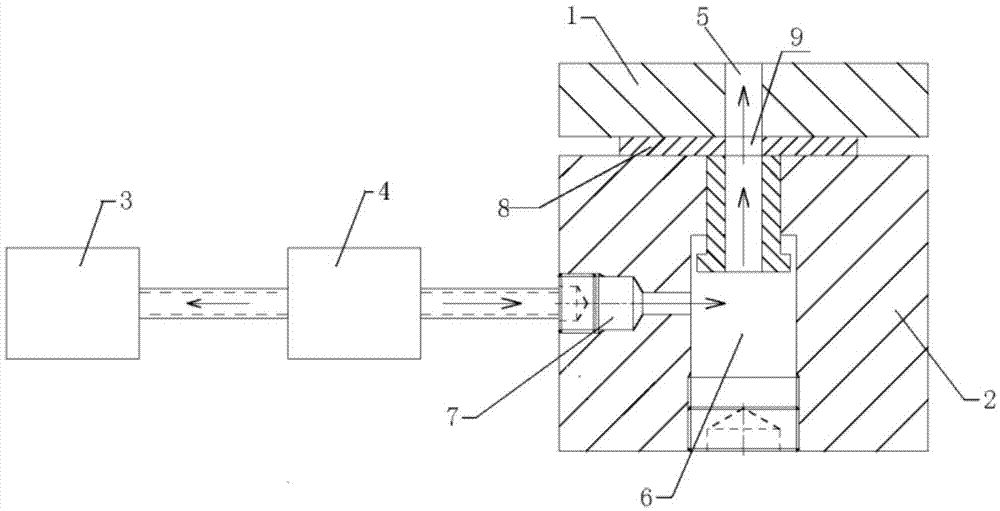

[0019] Such as figure 1 As shown, a punching die punching small hole leak-proof punching detection device is installed on the stamping equipment. The stamping equipment includes an upper die 1, a lower die 2 and a control system 3. The detection device includes an air pressure detection and feedback system 4, The first air hole 5 formed on the upper mold, the second air hole 6 and the third air hole 7 formed on the lower mold, the first air hole, the small hole 9 on the stamping part 8, the second air hole The air hole and the third air hole are connected in sequence to form an air flow channel, and the air flow channel communicates with the air outside the upper mold and the air pressure detection and feedback system, and the air pressure detection and feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com