Profile supporting system used for car door window frame reworking

A surface support and working technology, applied in workbenches, manufacturing tools, etc., can solve problems such as affecting the mechanical properties and service life of the final product, unable to completely eliminate sheet metal waves, poor flatness of window frames, etc., and reach the scope of use. Wide, automatic control, flexible use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

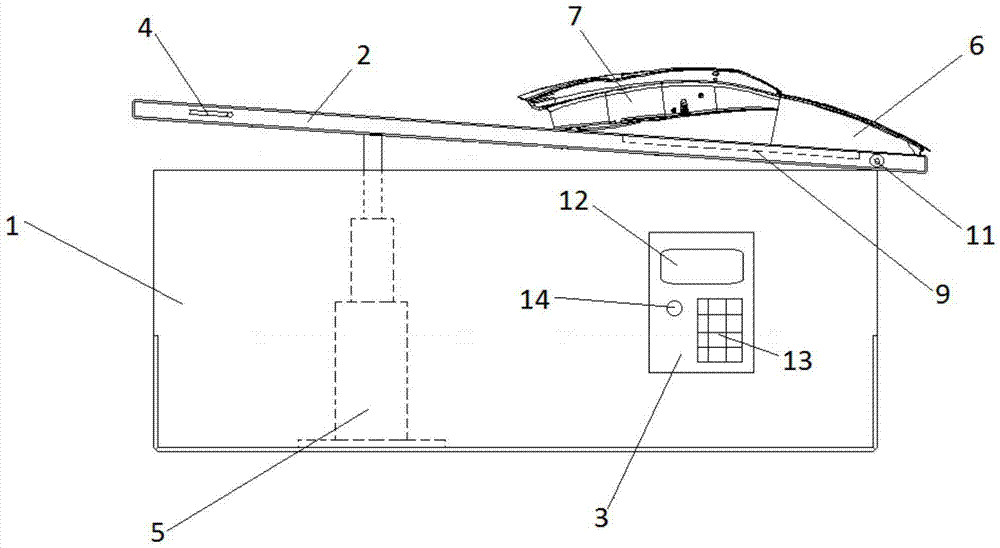

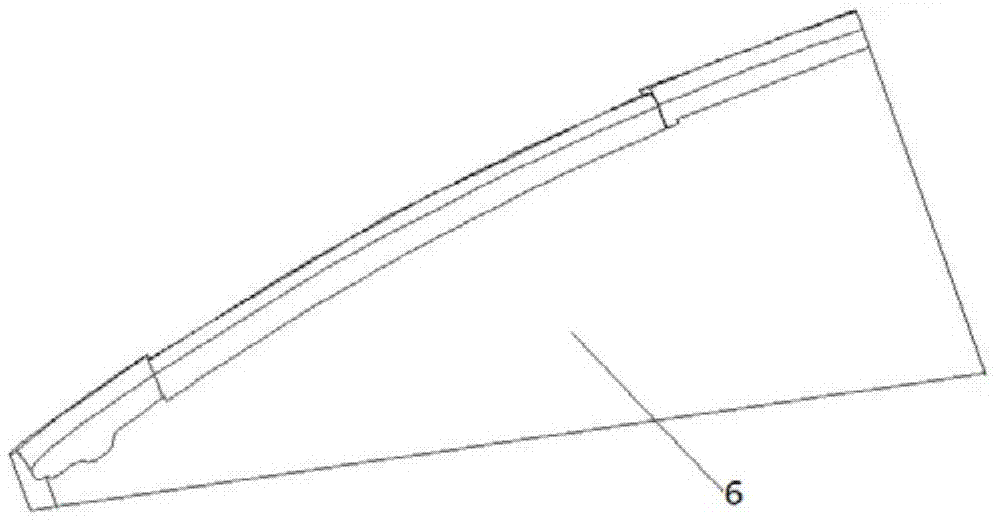

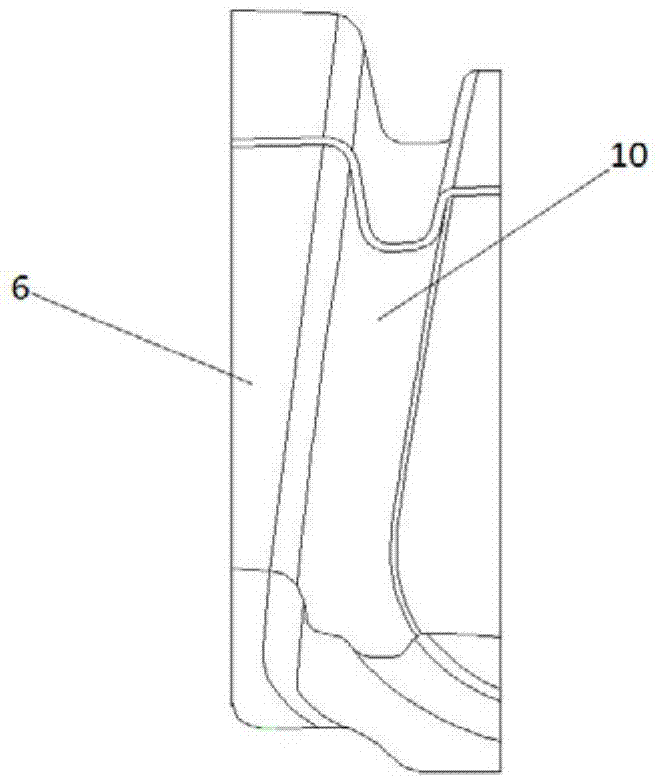

[0030] Such as figure 1 As shown, a profile support system for the rework of car door and window frames, the profile support system includes a rework base 1, a rework rework set on the rework base 1 and hinged to the rework base 1 through a hinge shaft 11 at one end. Table 2, the angle sensor 4 arranged on one side of the rework table 2, the telescopic hydraulic cylinder 5 arranged in the rework base 1 and connected to the rework table 2 in transmission, the telescopic hydraulic cylinder 5 and the angle sensor 4 electrically connected respectively The electrical control box 3 and the profile support block 6 arranged on the rework table 2 are pushed by the telescopic hydraulic cylinder 5 , and the rework table 2 is reciprocally rotatable around the hinge shaft 11 and is set on the rework base 1 . Wherein, the rework table 2 is also provided with a built-in sliding guide rail 9, and the bottom of the profile support block 6 is provided with a slider matching with the built-in sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com