A quick disassembly and assembly structure for furniture hinges

A furniture and hinge technology, applied in the field of quick disassembly and assembly structure, can solve the problems of difficult disassembly and assembly of users, inconvenient disassembly and assembly, and inability to meet the needs of use, and achieves the effect of stable assembly, avoiding difficulty in disassembly, rapid disassembly and assembly, and stable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

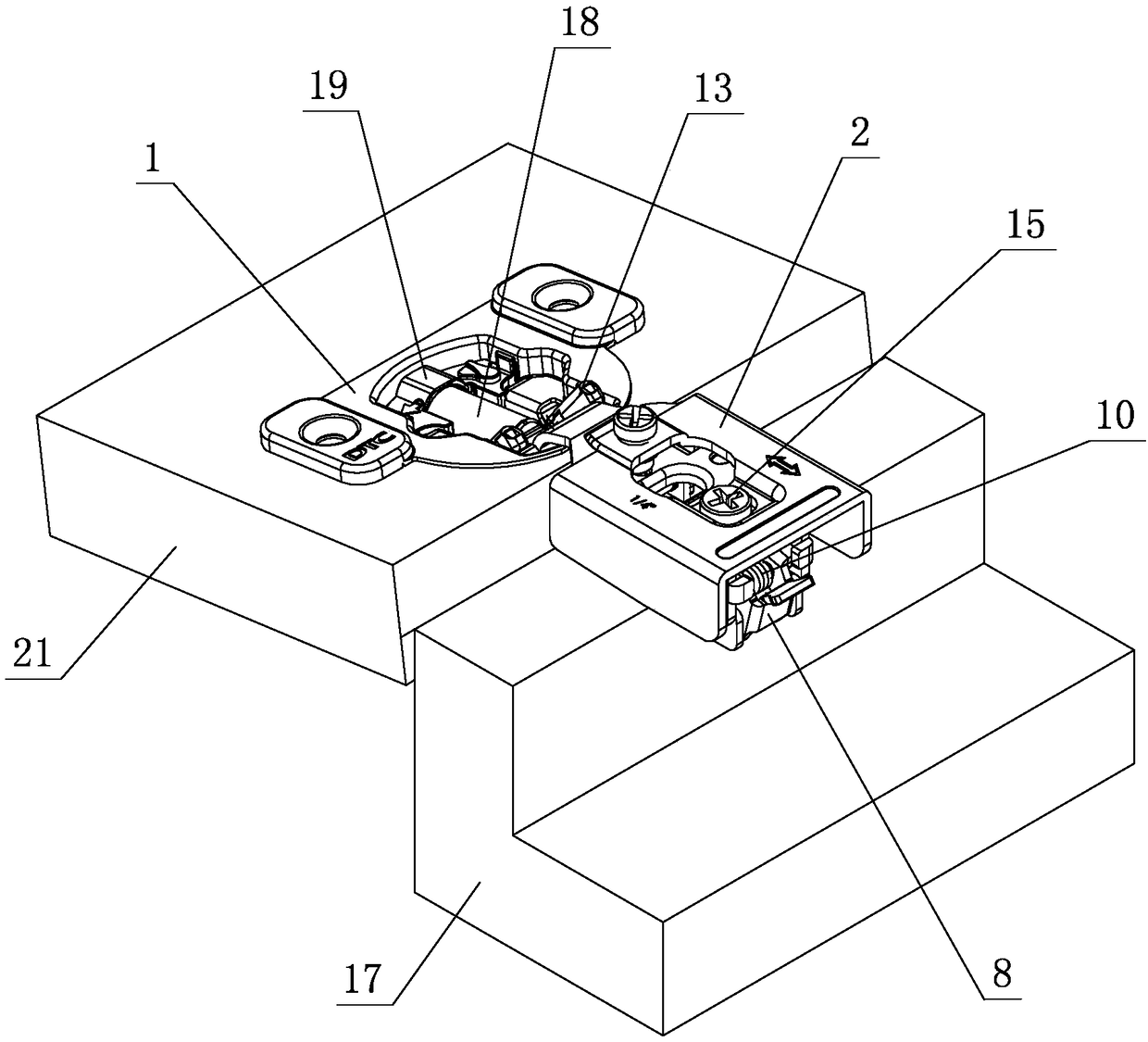

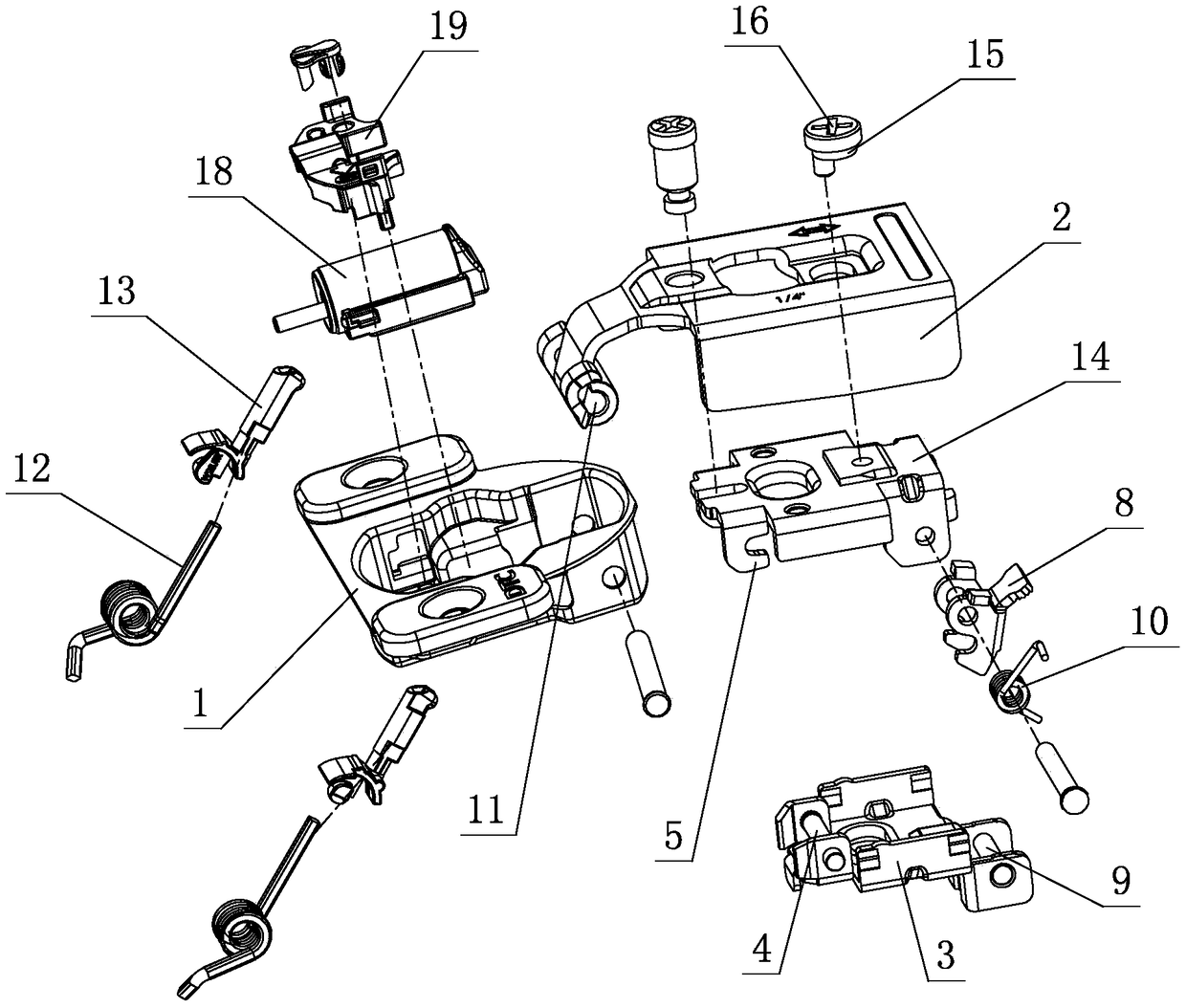

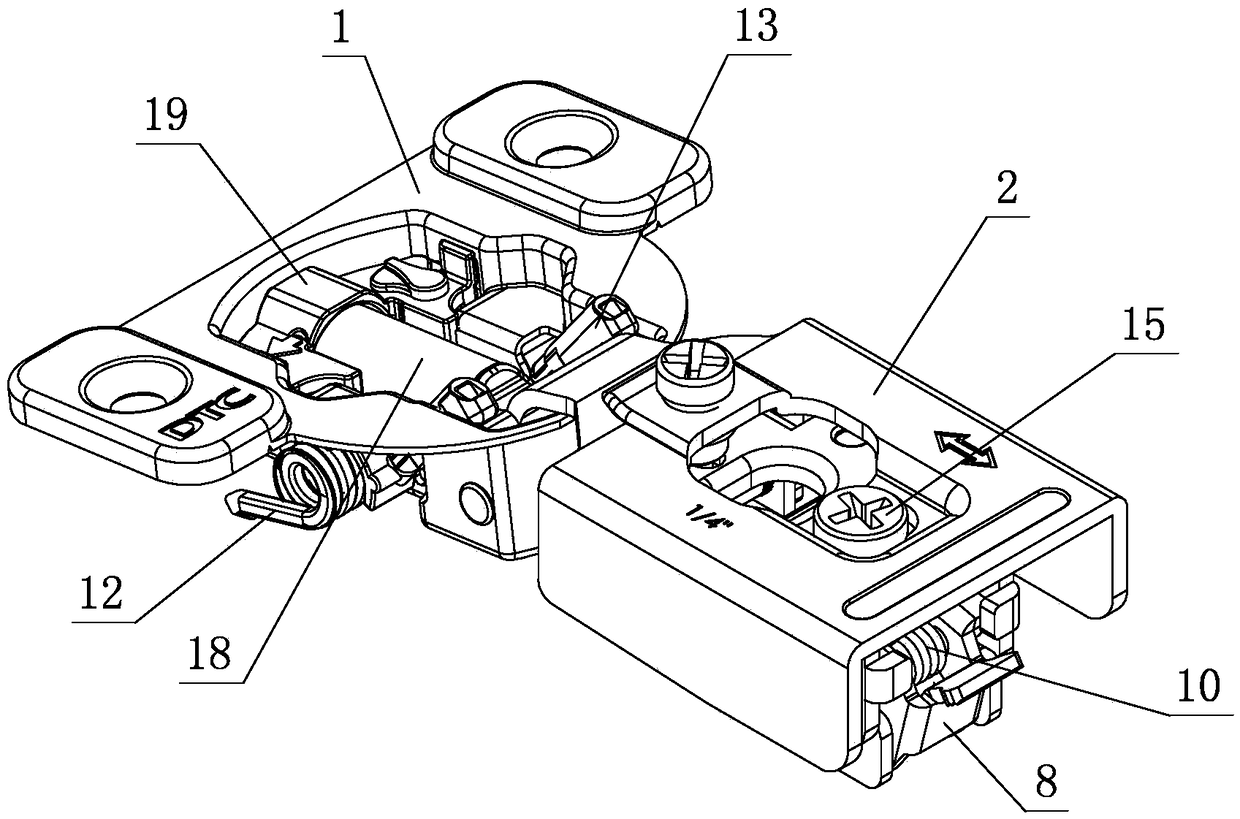

[0027] see Figure 1-Figure 5 , the quick disassembly structure of the furniture hinge, including the movable cup holder 1, the connecting arm 2 and the fixed base 3, one end of the connecting arm 2 is hinged with the movable cup holder 1, the other end is connected with the fixed base 3, and the front end of the fixed base 3 A positioning part 4 is provided, and the connecting arm 2 is provided with a positioning matching part 5 corresponding to the positioning part 4. An elastic clamping assembly is also provided between the rear end of the fixed base 3 and the connecting arm 2; the front end of the fixed base 3 is locked by the positioning part 4. Installed on the positioning matching part 5 of the connecting arm 2, the rear end of the fixed base 3 cooperates with the connecting arm 2 through an elastic clamping assembly, so as to realize the quick disassembly and stable connection of the fixed base 3 and the connecting arm 2.

[0028] Further speaking, the elastic clamping...

no. 2 example

[0038] see Figure 6-Figure 8 , the quick disassembly and assembly structure of the furniture hinge is different from the first embodiment in that:

[0039] One end of the elastic clamping component is swingably or slidingly arranged on the fixed base 3 , and the other end is clamped with the connecting arm 2 .

[0040] The adjustable wrench 8 is swingably arranged on the rear end of the fixed base 3, and the clamping part 9 is arranged on the rear end of the connecting arm 2, and the rear end of the fixed base 3 is detachable from the clamping part 9 at the rear end of the connecting arm 2 through the adjustable wrench 8. card loaded.

[0041] The return spring 10 at least includes a support leg acting on the fixed base 3 at one end and a support leg acting on the adjustable wrench 8 at the other end. The adjustable wrench 8 elastically swings on the rear end of the fixed base 3 through the return spring 10 .

[0042] The adjustment assembly includes a push element 14 and a...

no. 3 example

[0046] see Figure 9-Figure 12 , the quick disassembly and assembly structure of the furniture hinge is different from the first or second embodiment in that:

[0047] The adjustment assembly includes a push element 14, an intermediate element 20, a front and rear adjustment element 15, and a left and right adjustment element 22. The positioning fitting part 5 and the support limit fitting part 7 are arranged on the push element 14, and one side of the middle element 20 is connected to the arm 2 Sliding connection, the other side of the intermediate element 20 is slidably connected to one side of the push element 14, the front end of the other side of the push element 14 is clamped on the positioning portion 4 of the fixed base 3 through the positioning fitting part 5, and through the supporting position limiting fitting part 7 acts on the support limit portion 6 of the fixed base 3, and the rear end of the other side of the push element 14 is detachably clamped with the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com