Manual pressure relief type check valve

A one-way valve and pressure relief technology, applied in the field of manual pressure relief check valve, can solve the problem of abnormal pressure relief gas, backflow and other problems, reduce the requirements of materials and processes, facilitate two-way control, and increase the maximum value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

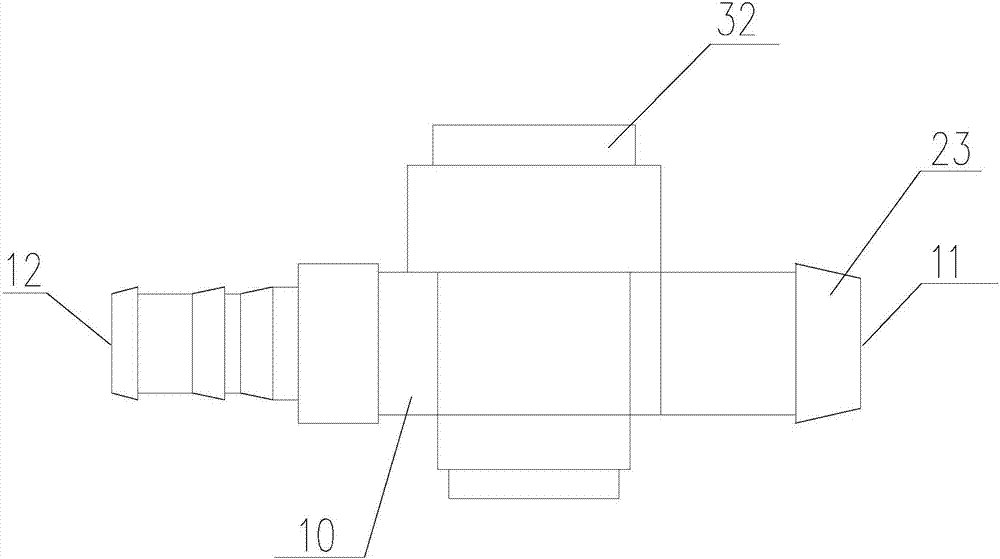

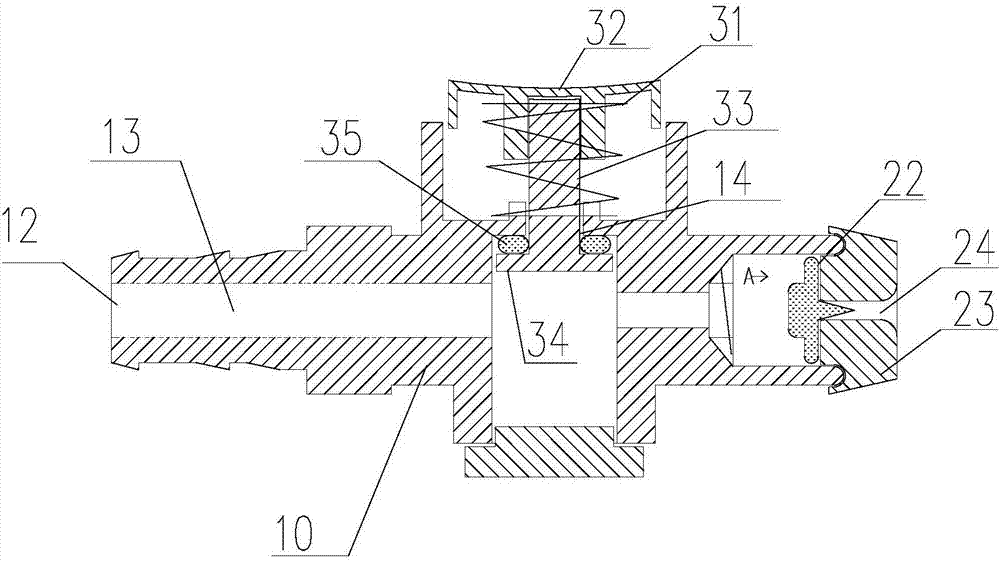

[0030] see Figure 1 to Figure 3 , the embodiment provides a manual pressure relief check valve, including a valve body 10, the valve body 10 has a first port 11 and a second port 12 that communicate with each other inside, and the first port 11 and the second port The channel between the ports 12 is a pressurized channel 13; a pressurization control device is installed at the first port 11.

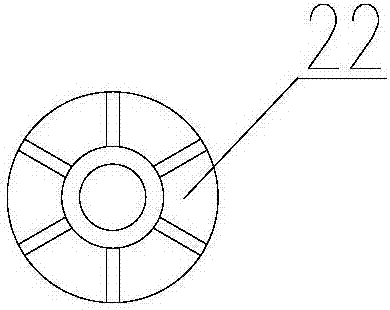

[0031] The pressure control device includes a closing element 22 and a sealing element 23; the sealing element 23 is fixed at the end face of the first port 11 (the sealing element 23 can be assembled on the first port 11 as an independent element, or can be assembled with the second port The end face of a port 11 is integrally formed), which has a pressurization through hole 24 that can communicate with the pressurization passage 13; the closure element 22 is elastically installed inside the pressurization passage 13, and the diameter of the closure element 22 is longer than the The di...

Embodiment 2

[0041] Such as Image 6 As shown, Embodiment 2 proposes a manually pressure-relief check valve, which differs from Embodiment 1 only in that the elastic element 31 is connected under the push rod to elastically support the push rod. The working principle of the second embodiment is similar to that of the first embodiment, and will not be repeated here.

Embodiment 3

[0043] Such as Figure 7 As shown, the manual pressure relief check valve proposed in Embodiment 3 differs from Embodiments 1 and 2 only in the design of the pressure relief control device. The pressure relief control device in Embodiment 3 includes a first screw cap 41 and the thimble 42 installed inside the first screw cap 41; the first screw cap 41 has an internal thread; the pressure relief port has an external thread that matches the internal thread of the first screw cap 41, so that the first screw cap 41 is screwed together On the pressure relief port; the pressure relief port has a connected middle passage 51 and a side hole 52, the middle passage 51 is connected with the pressurized passage; the thimble 42 is located in the middle passage 51, which is based on the first screw cap 41 and relative to the pressure relief The degree of screwing of the mouth opens or closes the side hole 52 accordingly.

[0044] In an optional solution, the pressure relief control device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com