Energy-saving submerged boiler

A boiler and boiler body technology, applied in the field of boilers, can solve the problems of waste, boiler condensed water cannot be recovered, singleness, etc., and achieve the effects of high heat absorption efficiency, reducing impact force, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

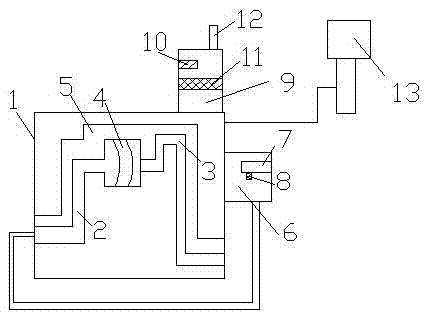

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] A sinking energy-saving boiler, comprising a boiler body, the boiler body 1 is provided with a lower liquid passage 2, the lower liquid passage 2 is connected to the upper liquid passage 3, and a buffer member 4 is provided between the upper liquid passage 3 and the lower liquid passage 1, and the buffer Part 4 is a spiral structure, and the two ends of the buffer part 4 are riveted with the upper liquid channel 3 and the lower liquid channel 2 respectively. within Road 5;

[0014] A water collector 6 is provided outside the boiler body 1, and the water collector 6 is a condensed water collection device, which is connected to the lower liquid channel 3, and a liquid level control rod 7 is arranged inside the condensed water collection device, and the liquid level control rod 7 There is a liquid sensor 8 on it, the liquid sensor 8 touches the water source to sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com