Heavy-duty vehicle frame road simulation test device

A test device and road simulation technology, which is applied in the direction of measuring device, vehicle test, machine/structural component test, etc., can solve the problems that are not easy to obtain, and the requirements for test personnel's technical reserves are high, so as to release the degree of freedom and shorten the test cycle, and the effect of improving the accuracy of fatigue tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

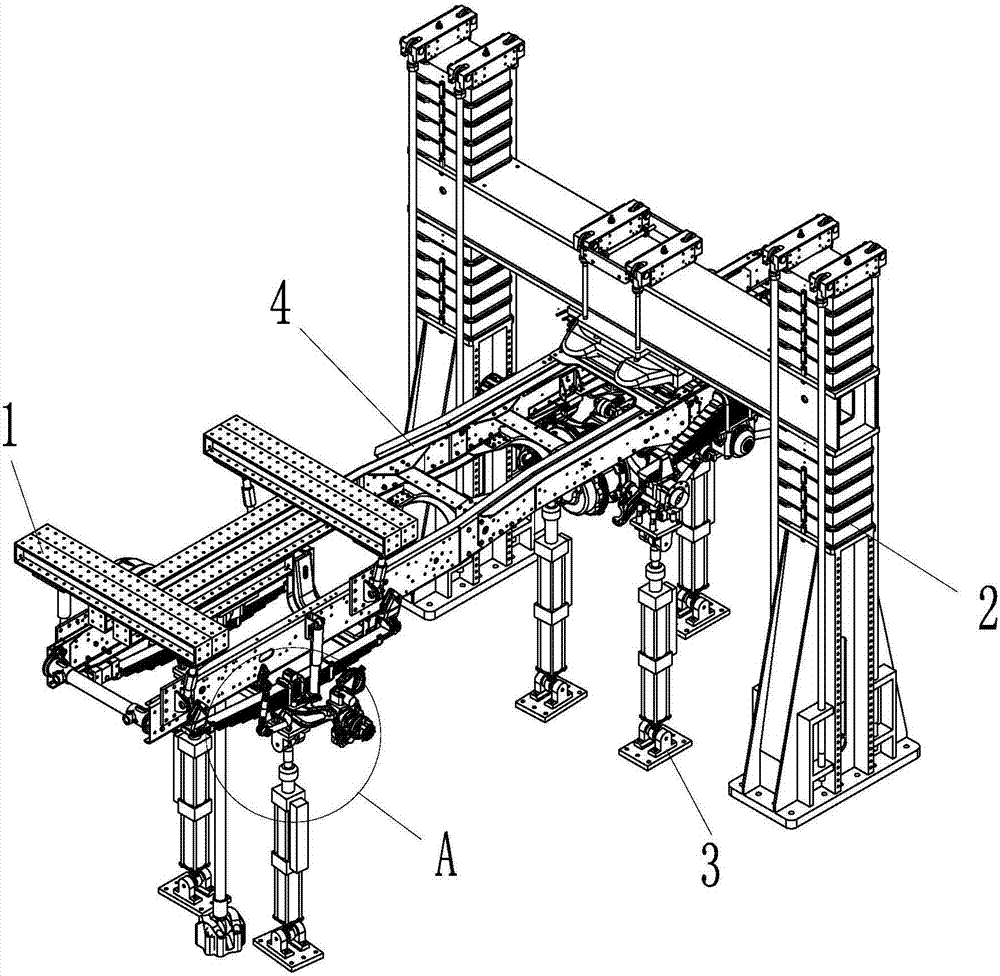

[0019] Such as figure 1 As shown, a heavy-duty vehicle frame road simulation test device is composed of a front-end fixing mechanism 1, a gantry 2 and six servo loading mechanisms 3. The front end fixing mechanism 1 is used to fix the front end of the vehicle frame assembly 4, the gantry frame 2 is used to fix the rear end of the vehicle frame assembly 4, and the six servo loading mechanisms 3 correspond to the six wheels of the vehicle frame assembly 4 one by one. The servo loading mechanism 3 loads the vertical load.

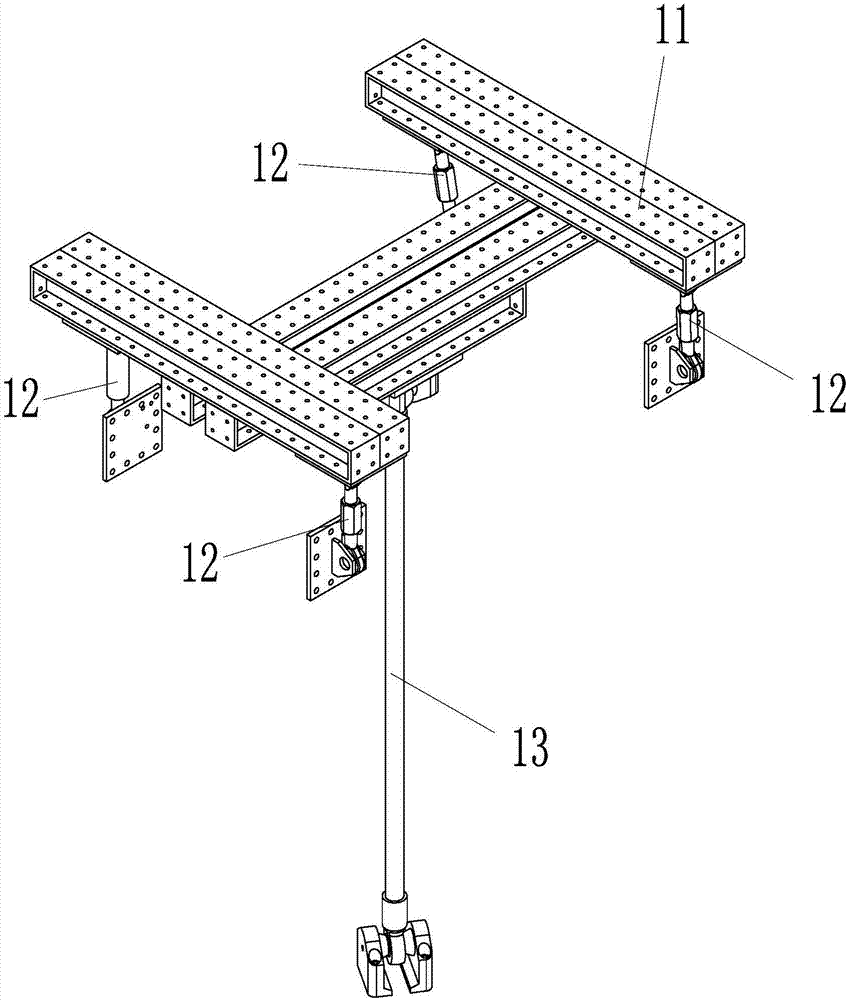

[0020] combine figure 1 — figure 2 As shown, the front end fixing mechanism 1 is composed of a horizontal fixing beam 11 , four vertical connecting rods 12 and a grounding connecting rod 13 . The four vertical connecting rods 12 are arranged in a rectangular shape, and the vertical connecting rods 12 and the grounding connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com