Light spot layout structure, surface shape measurement method and exposure field control value calculation method

一种布局结构、测量方法的技术,应用在光刻领域,能够解决离焦、不能被采用等问题,达到提高扫描测量效率、运动速度提高、好通用性和适用性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention is described in detail below in conjunction with accompanying drawing:

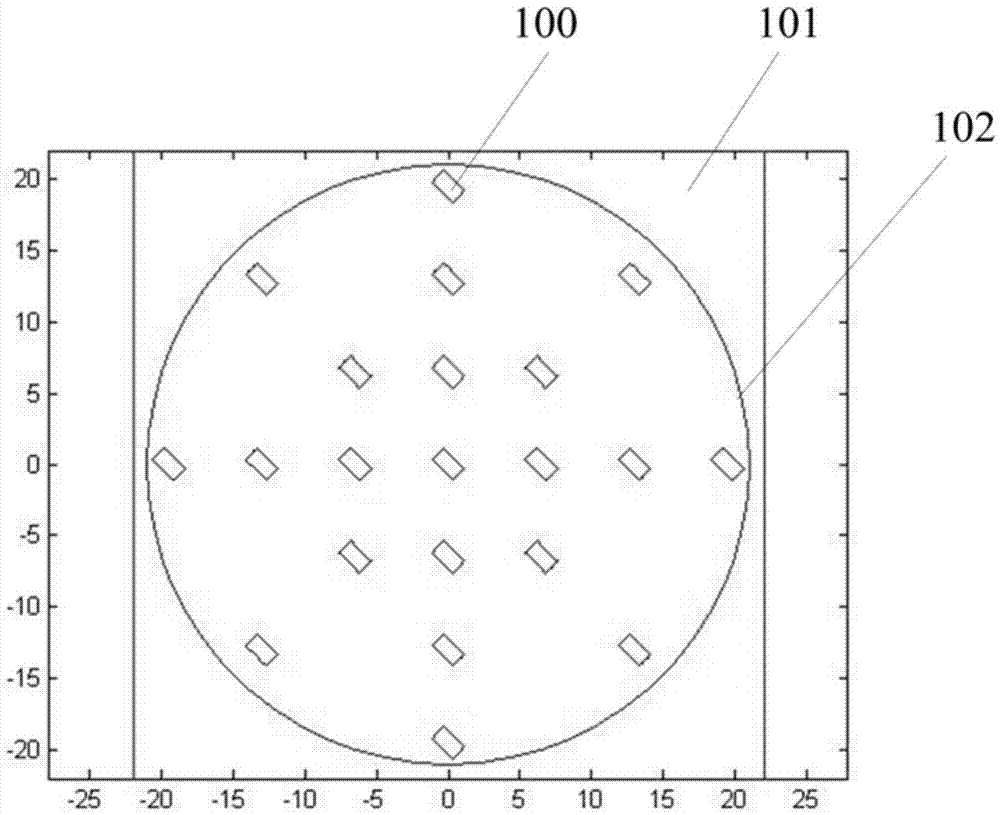

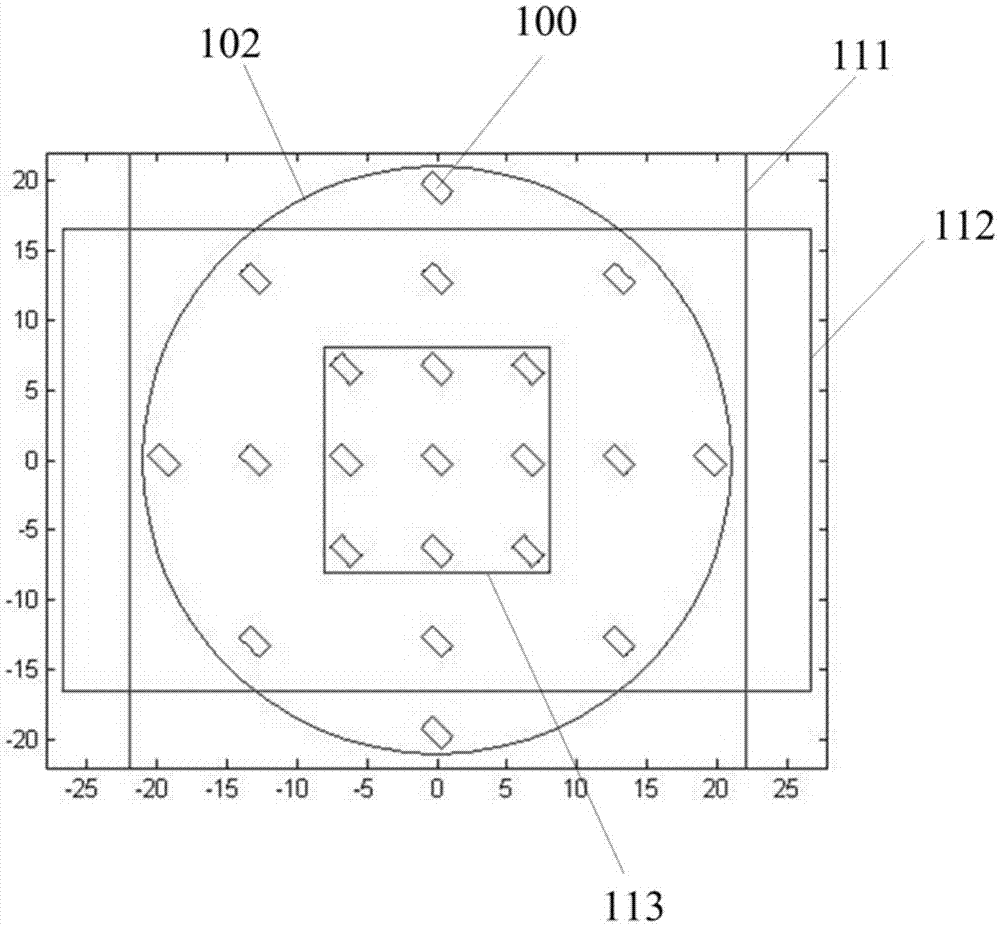

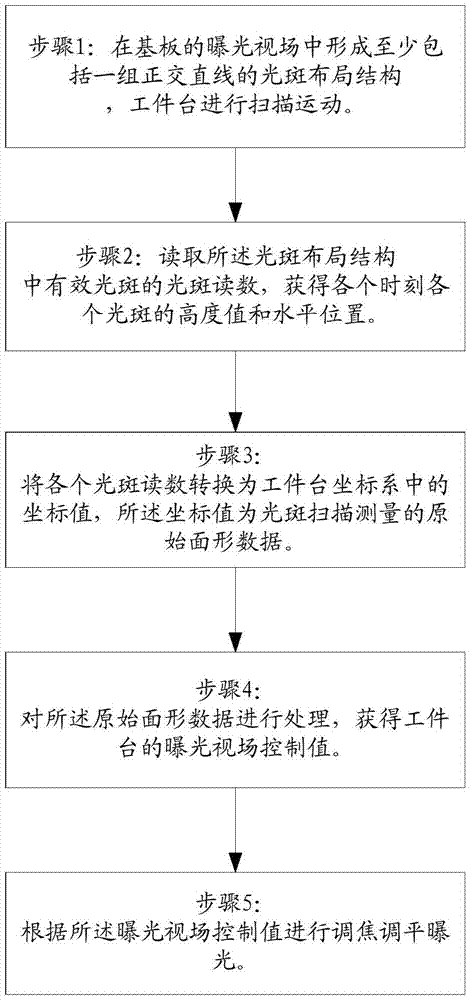

[0057] refer to figure 1 and Figure 4 , the light spot layout structure of the present invention includes a plurality of measurement light spots, the plurality of measurement light spots form at least one set of orthogonal straight lines, the measurement light spots on the orthogonal straight lines are arranged outwardly from the center, and the measurement on each straight line The number of light spots is at least 4, and the measurement light spots measure the shape of a plane. As a specific application, a light spot measurement system is proposed.

[0058] Specifically, the spot measurement system applied to the spot layout structure of the present invention includes a spot projector 400, a spot receiver, and a signal processing unit. The center of a group of orthogonal straight lines diverges outwards to form a light spot layout structure and reflection, the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com