Sieve cleaners, sieve unit, and methods

A technology of screen cleaner and screen surface, applied in the field of screen cleaner, can solve problems such as screen surface blockage, and achieve the effect of reducing screen surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

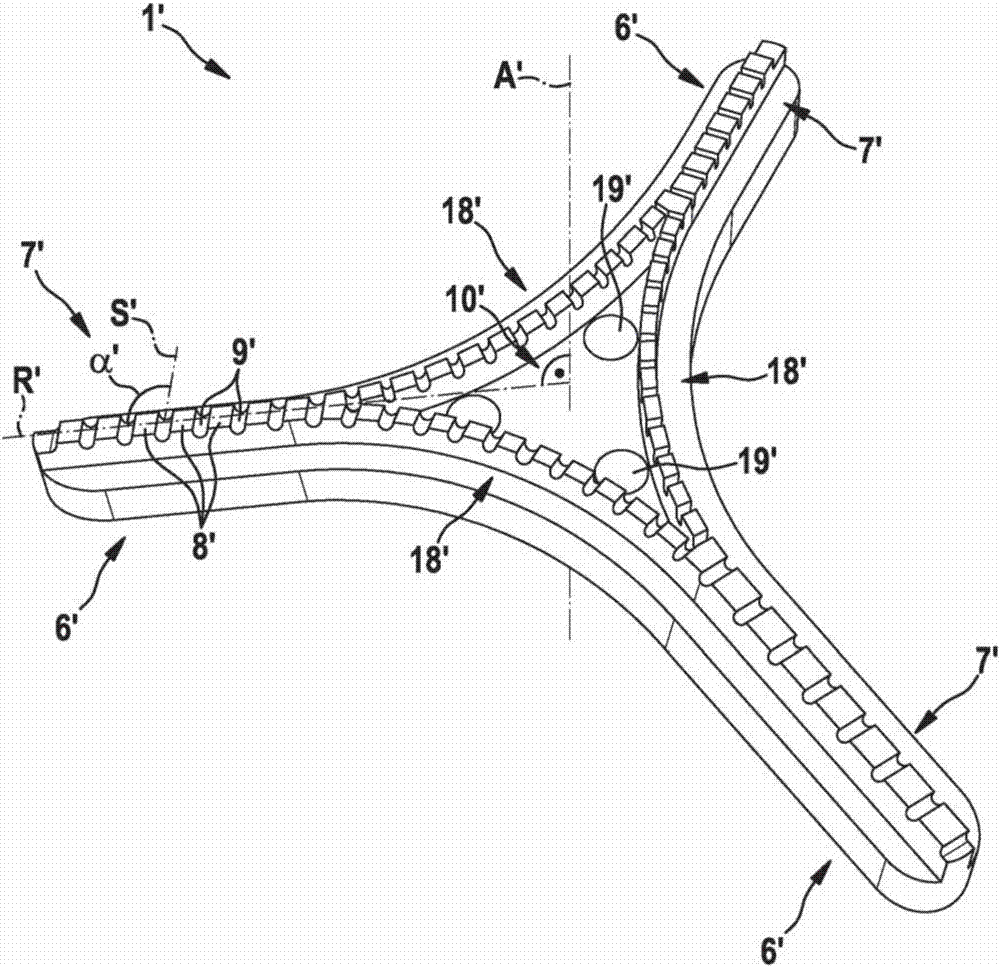

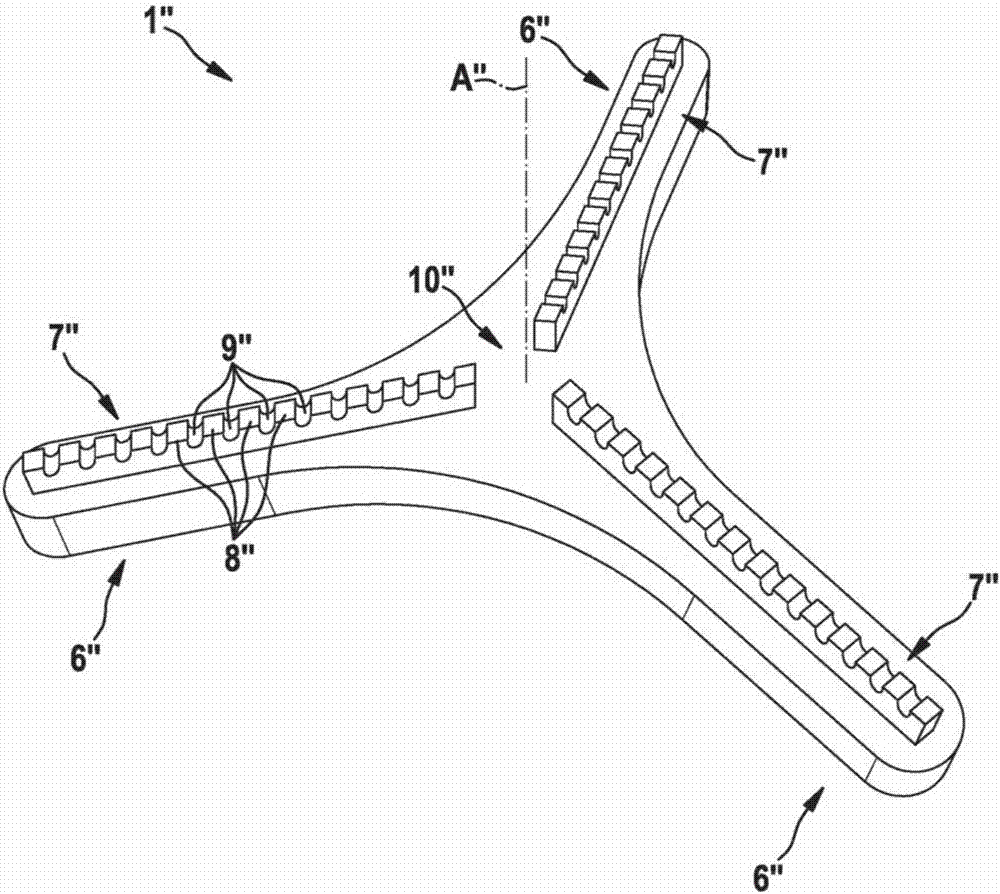

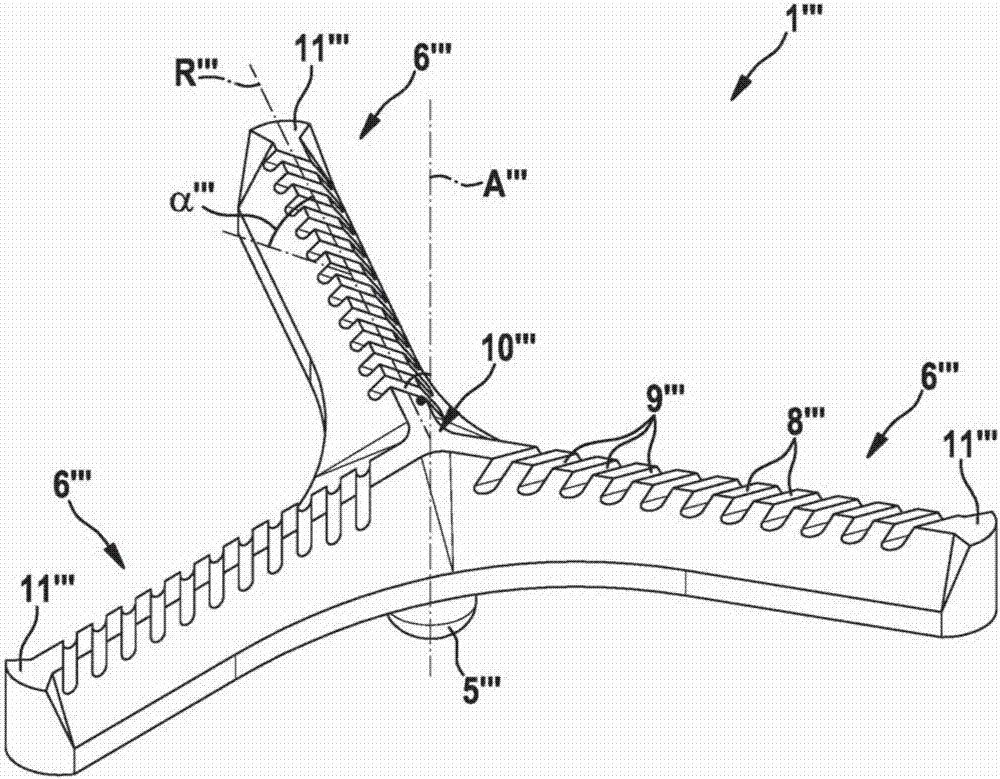

[0046] Such as figure 1 The shown first embodiment of the sieve cleaner 1 ′ includes rocking feet which are not visible here. The rocking foot extends along the main axis A' of the sieve cleaner 1', which at the same time also forms the axis of the center of gravity. it is in accordance with Figure 5 to Figure 9 The swing foot 5 in the fourth embodiment of the present invention is formed in the same way.

[0047] Extending from the central region 10 ′ of the sieve cleaner 1 ′ are three cleaning elements designed as cleaning arms 6 ′, which are distributed uniformly around the center of gravity axis A′ in the circumferential direction. Each of said cleaning arms 6' comprises a respective cleaning zone 7'. Each of said cleaning zones 7' has a plurality of rectangular cleaning surfaces 8', which extend perpendicularly to the axis A' of the center of gravity and are respectively configured to surface-contact a screen surface not shown here (see for this Figure 10 , which sho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap