Footings for circular knitting machines for hosiery

A footing, circular technology applied in the field of footings of circular knitting machines for hosiery, capable of solving difficult contrasting, heavy, etc. problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

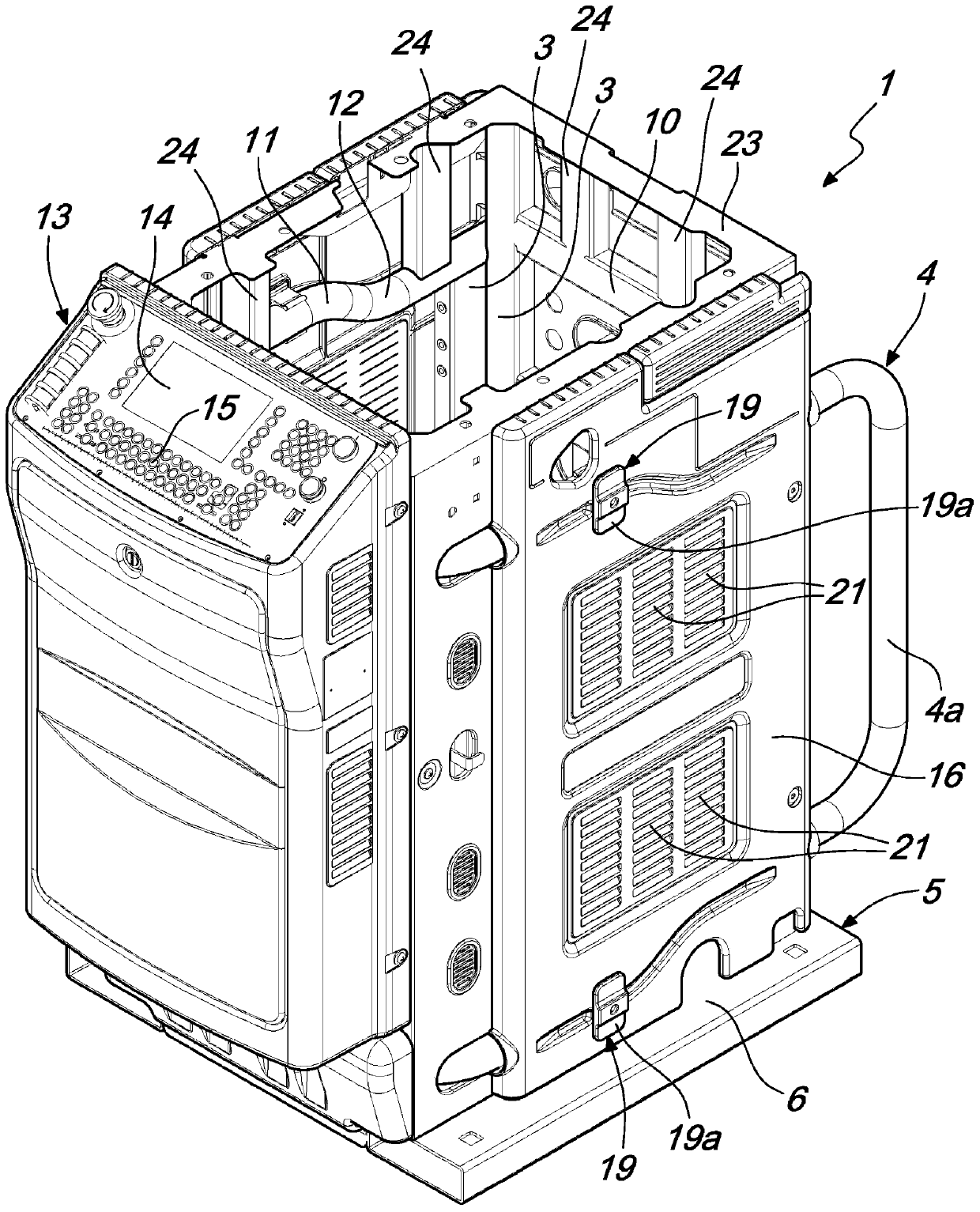

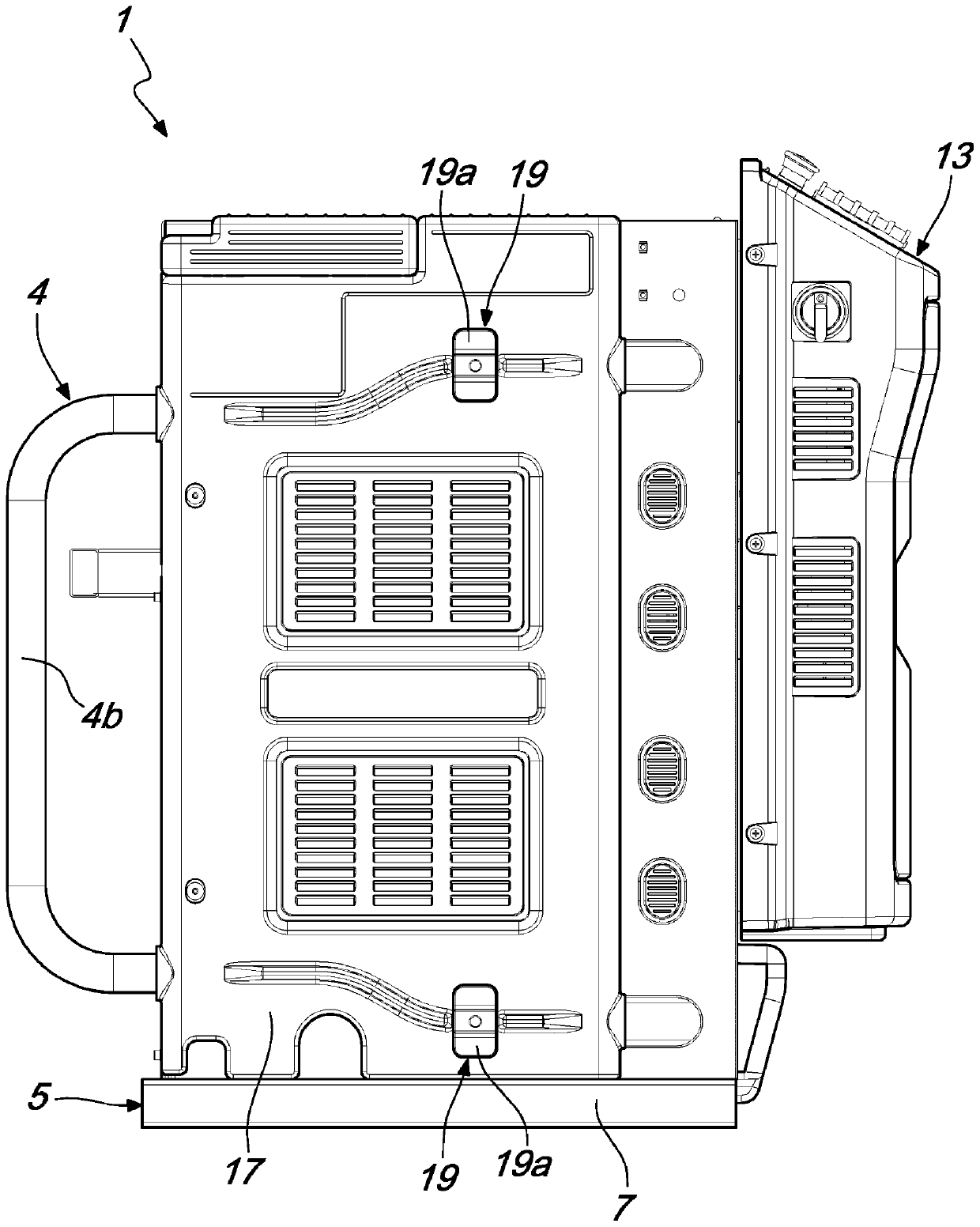

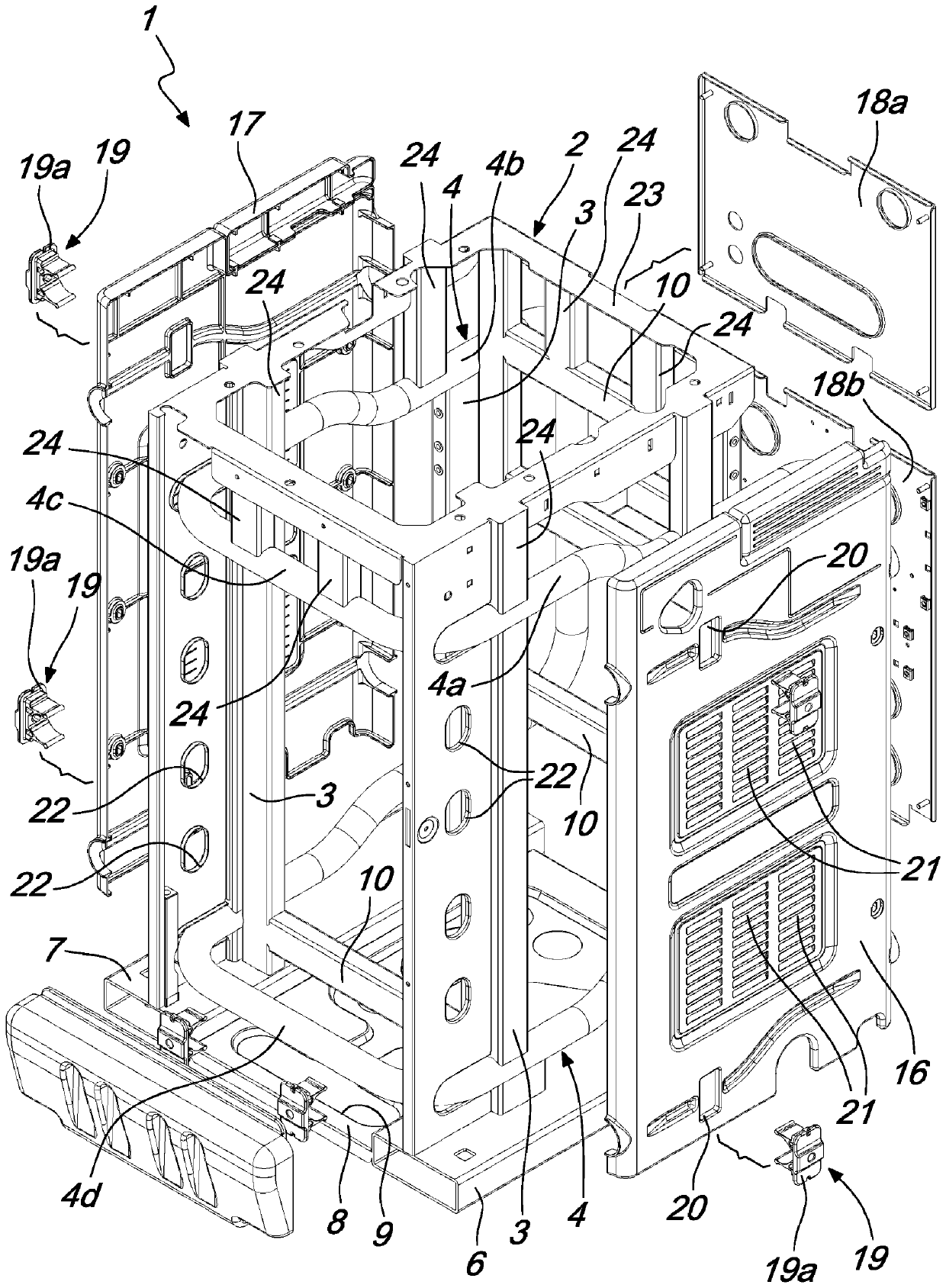

[0023] With reference to the drawings, according to the invention, the footing of a circular knitting machine for hosiery and the like generally indicated by the reference number 1 comprises a support structure 2 comprising, according to the invention, struts extending in a substantially vertical direction 3, and at least one tubular reinforcing element 4 rigidly connected to and interconnected with the strut 3.

[0024] Suitably, the struts 3 consist of metal tubular profiled elements and of elements made by bending sheet metal, preferably steel, which can be assembled to each other in a manner known per se, preferably by welding.

[0025] The struts 3 extend from a base member 5 having a rectangular plan shape and lying on a substantially horizontal plane. The struts 3 are arranged approximately along the four vertical edges of an imaginary parallelepiped (cuboid).

[0026] In more detail, the base element 5 consists of two tubular shaped elements 6, 7 with a rectangular cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com