Solenoid

A solenoid and coil technology, applied to electromagnets, valve details, electrical components, etc., can solve the problems of increased material costs and manufacturing costs, increased weight of movable parts, and increased axial length, etc., to achieve the suppression of material costs , Responsive deterioration is suppressed, and assembly property is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

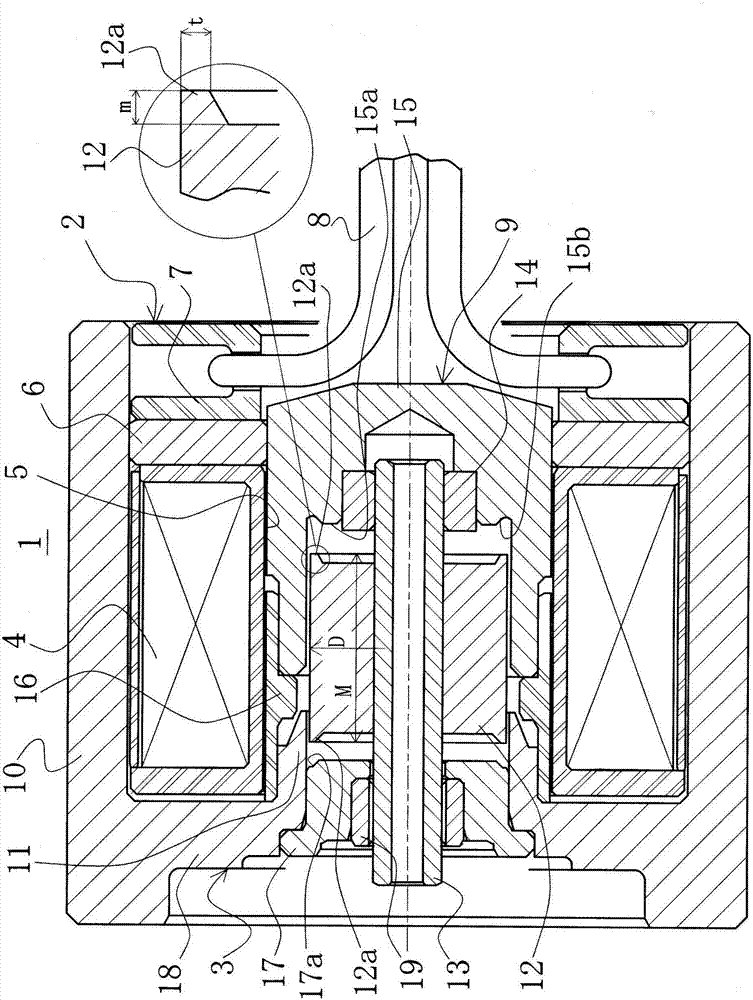

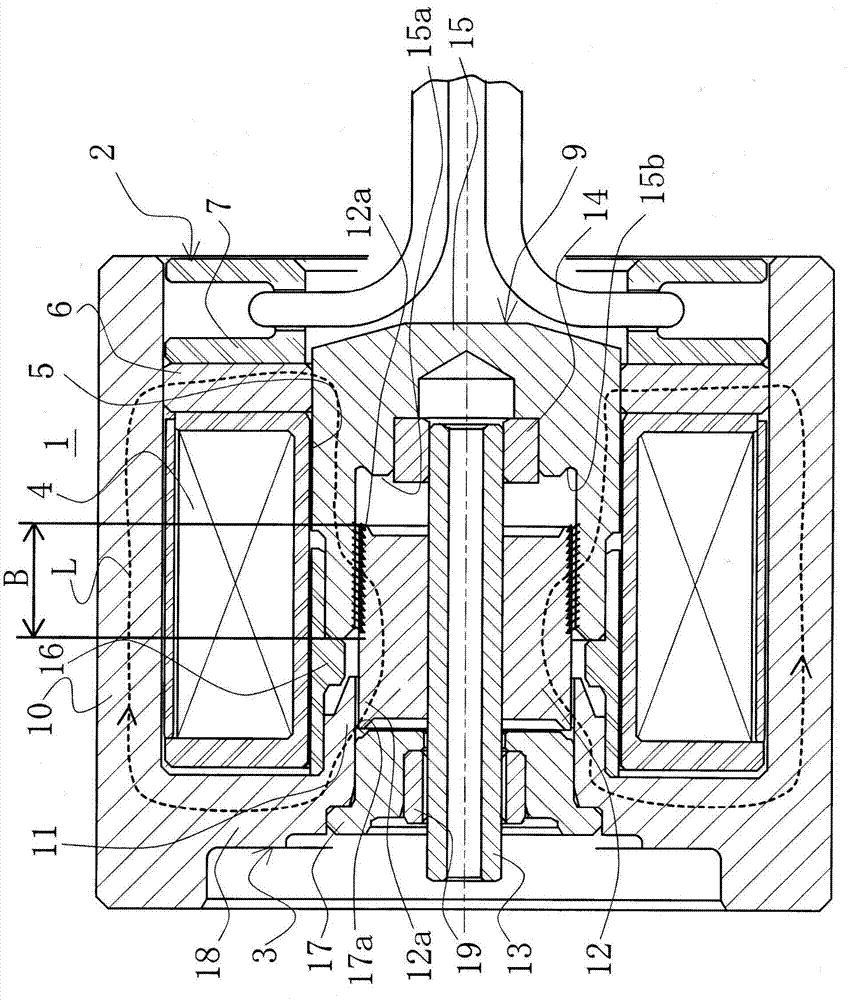

[0050] refer to figure 1 and figure 2 , the solenoid of Embodiment 1 of the present invention will be described.

[0051] The solenoid 1 is configured by integrating a molded coil 2 and a solenoid body 3 .

[0052] The molded coil 2 is wound with a coil 4, and a hole 5 recessed toward the solenoid main body 3 side is formed at the center of the coil 4. As shown in FIG.

[0053] In addition, on the side opposite to the solenoid main body 3 of the molded coil 2, an annular plate 6 is provided adjacent to the coil 4, and a molded portion 7 forming the bottom surface of the hole 5 is provided in front of the plate 6. . Inside the mold portion 7 , the coil wire drawn out from the coil 4 is connected to a lead wire 8 . The plate 6 is formed of a magnetic material.

[0054] On the other hand, the solenoid main body 3 is provided with: a column part 9 inserted into the hole 5 of the molded coil 2 at the axial center; A case 10 covering the outer periphery of the molded coil 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com