Regenerated rice stubble righting device

A technology of ratooning rice and stubble retention, which is applied in the lifting device of agricultural machinery, agriculture, application, etc. It can solve the problems of heavy workload, affecting the germination of rice regeneration tillers, and not suitable for large-area paddy fields, and achieve the effect of increasing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

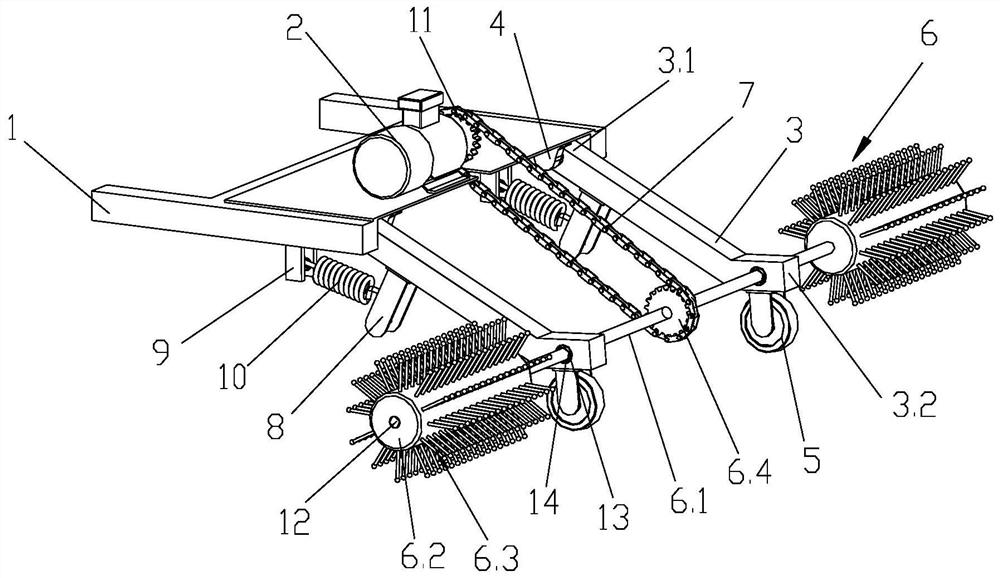

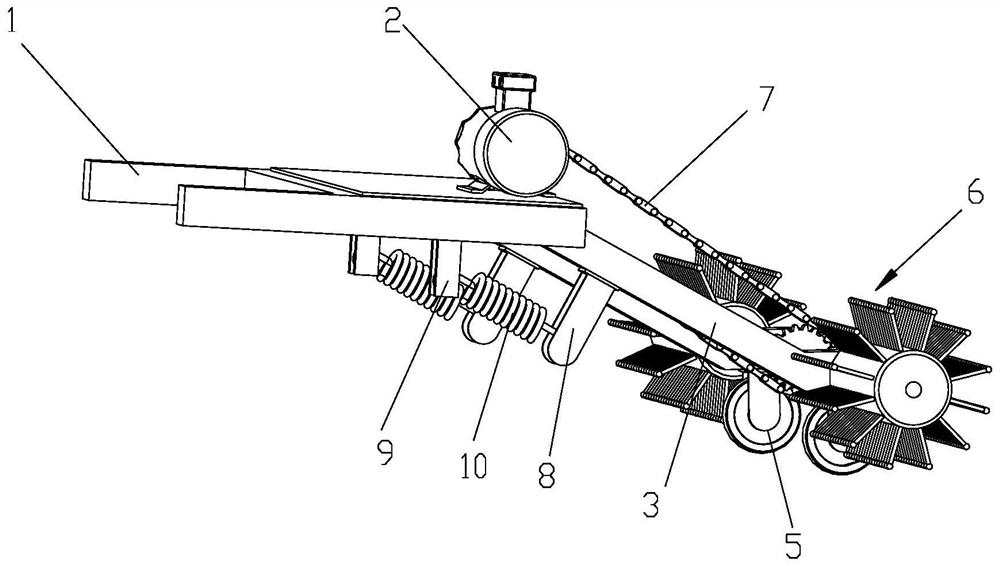

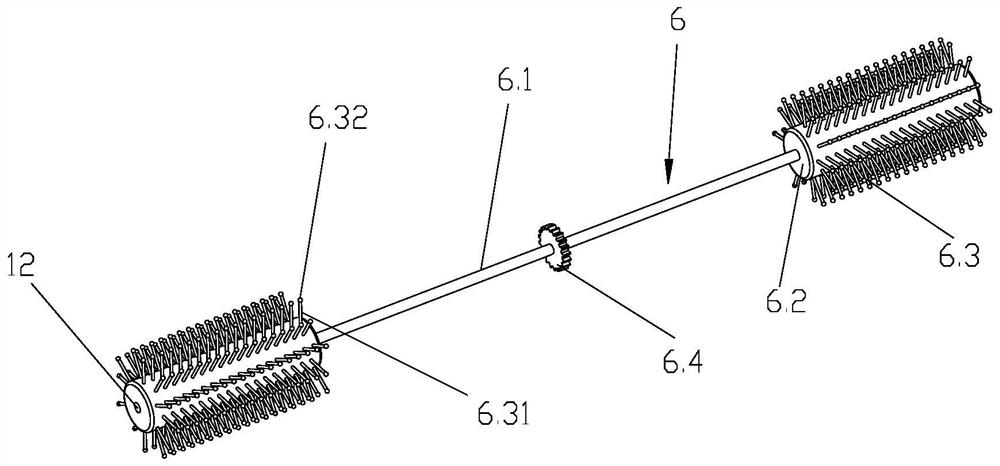

[0024] A kind of regenerative rice stubble straightening device of the present invention as shown in the figure is installed on the tail of harvester 15 for carrying out righting operation to ratooned rice stubble, and it comprises the frame platform 1 that is fixedly connected with harvester 15 tail chassis, The motor 2 arranged on the frame table 1, and two movable connecting rods 3 which are arranged obliquely on the lower side of the rear side of the frame table 1 and hinged thereto, the frame table 1 and the movable connecting rods 3 are all made of metal materials. member. Each movable link 3 has a hinged end 3.1 and a free end 3.2, the hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com